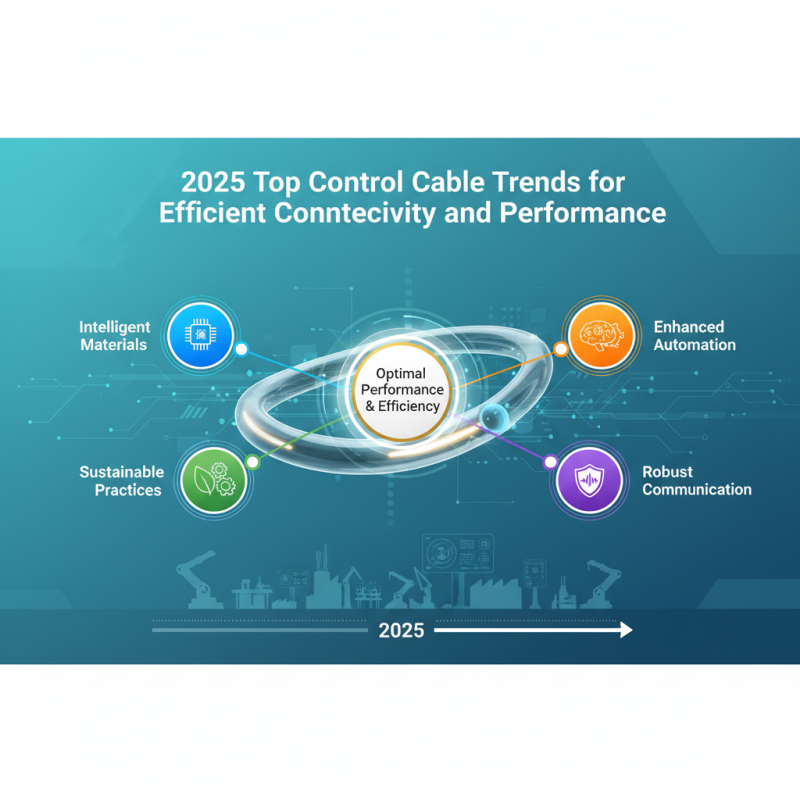

2025 Top Control Cable Trends for Efficient Connectivity and Performance

In the rapidly evolving world of industrial connectivity, the significance of control cables is becoming increasingly pronounced. As we look toward 2025, industry experts predict that advancements in control cable technology will play a critical role in enhancing both efficiency and performance across various sectors. Renowned control cable specialist, Dr. Emily Thompson, emphasizes this trend, stating, "The future of control cables lies in their ability to provide seamless connectivity while ensuring optimal performance under demanding conditions." Her insights highlight the necessity for innovation in materials and design to meet the growing demands of automation and smart systems.

As industries embrace digital transformation, the role of control cables in facilitating robust communication and automation will become ever more vital. Emerging trends such as the integration of intelligent materials and the shift toward sustainable practices are set to redefine how control cables are manufactured and utilized. This drive for greater efficiency and performance not only promises to optimize operational workflows but also ensures that businesses remain competitive in an increasingly interconnected world.

In conclusion, the landscape of control cables is on the brink of significant change, with promising developments on the horizon. Understanding these emerging trends will be essential for industry stakeholders looking to harness the full potential of control cables in their operations, ultimately paving the way for a smarter and more efficient future.

Emerging Materials in Control Cable Technology for 2025

As we look ahead to 2025, the landscape of control cable technology is set to be transformed by the introduction of innovative materials that enhance connectivity and performance. One of the most promising developments is the utilization of advanced polymers and composites, which offer superior insulation properties and resistance to environmental factors. These materials not only contribute to improved durability but also facilitate greater flexibility, allowing for more versatile applications in various industries.

Tip: When selecting control cables for your projects, consider materials that provide resistance to chemicals and extreme temperatures to ensure longevity and reliability in demanding environments.

Additionally, the integration of smart materials, such as self-healing polymers, is gaining traction. These materials can automatically repair minor damages, thus reducing maintenance costs and downtime. As industries move towards automation and smart technologies, incorporating these advanced materials into control cables will be crucial to maintain efficiency and performance standards.

Tip: Keep an eye on developments in smart material research, as these innovations can lead to significant advancements in control cable applications, potentially revolutionizing how we approach connectivity and automation.

The Role of Smart Sensors in Enhancing Control Cable Performance

The integration of smart sensors into control cable systems is revolutionizing performance and connectivity across various industries. These advanced sensors provide real-time monitoring of cable conditions, ensuring that any issues, such as wear or connection failures, are detected swiftly. By facilitating immediate feedback, smart sensors enable preventive maintenance strategies, reducing downtime and extending the life of control cables. As industries strive for greater efficiency and reliability, the adoption of these technologies is becoming increasingly vital.

Moreover, the data collected by smart sensors can be analyzed to optimize cable designs and installations. This feedback loop not only improves the immediate performance of control cables but also informs future innovations in cable technology. Enhanced metrics, such as temperature, pressure, and electromagnetic interference levels, can guide engineers in developing more resilient and efficient cable solutions. In this evolving landscape, smart sensors are key players in driving the next generation of control cable performance, ensuring seamless operation in complex systems.

Trends in Eco-Friendly Manufacturing Practices for Control Cables

The manufacturing landscape for control cables is undergoing a transformative shift with a strong emphasis on eco-friendly practices. As environmental regulations become increasingly stringent, manufacturers are focusing on sustainable material sourcing and production techniques.

According to a recent industry report by MarketsandMarkets, the global green cable market is expected to grow from $1.5 billion in 2020 to $3 billion by 2025, highlighting the significant demand for environmentally conscious products. This shift not only caters to consumer preferences but also aligns with a broader commitment to reducing carbon footprints in industrial production.

Eco-friendly practices now encompass the use of recyclable materials, such as thermoplastics and biodegradable additives, which replace traditional, less sustainable options.

Furthermore, innovations in manufacturing processes, including energy-efficient machinery and waste reduction systems, are being adopted. A detailed analysis by ResearchAndMarkets indicates that companies implementing sustainable practices can reduce operational costs by up to 25%, providing a compelling case for manufacturers to invest in green technologies.

By prioritizing ecological responsibility, the control cable sector is enhancing both its marketability and performance, ultimately contributing to more efficient connectivity solutions in the long run.

Advancements in Connectivity Solutions for Industrial Applications

The industrial sector has witnessed rapid advancements in connectivity solutions, driven by the increasing need for reliable and efficient communication systems. According to a report by Market Research Future, the global industrial connectivity market is projected to reach $90 billion by 2025, reflecting a compound annual growth rate (CAGR) of 25.5%. This surge is largely attributed to the rise of Industry 4.0, where smart factories are utilizing control cables to enhance connectivity between machines, sensors, and control systems.

One of the pivotal trends in control cable technology is the integration of IoT (Internet of Things) capabilities. As reported by the International Data Corporation (IDC), over 41 billion connected devices are expected to be operational by 2025, necessitating robust and efficient networking solutions. This has led to the development of advanced control cables that support faster data transfer rates and improved signal integrity.

Manufacturers are increasingly focusing on creating cables that are not only durable but also resistant to environmental factors such as temperature fluctuations and electromagnetic interference, ensuring uninterrupted performance in various industrial applications.

Moreover, as industries embrace automation, the demand for high-speed data communication has surged. A study by Grand View Research indicates that the demand for industrial control cables will grow significantly, driven by the need for secure and efficient data exchange in automated systems. This evolving landscape emphasizes the importance of innovative connectivity solutions that can meet the increasing performance demands of modern industrial environments. As a result, advancements in control cable technology will play a crucial role in enhancing operational efficiency and ensuring seamless connectivity across various industrial applications.

Future-Proofing Control Cables: Adaptability and Versatility Needs

In the rapidly evolving landscape of technology, the future of control cables hinges on their adaptability and versatility. As industries strive for automation and increased efficiency, control cables must be designed to accommodate a wide range of applications and environments. This adaptability ensures that manufacturers can easily integrate new technologies without overhauling existing infrastructure, ultimately leading to significant cost savings and reduced downtime.

Moreover, the versatility of control cables is essential in meeting the diverse needs of various sectors, from manufacturing to telecommunications. Increasing demand for smart solutions means that control cables must support enhanced functionalities, such as data transmission and power delivery, within the same system. These multifunctional capabilities not only streamline operations but also future-proof the connectivity solutions, allowing companies to remain agile in an ever-changing technological landscape.

As a result, the emphasis on innovation in control cable design will play a crucial role in fostering future developments across multiple industries.

Related Posts

-

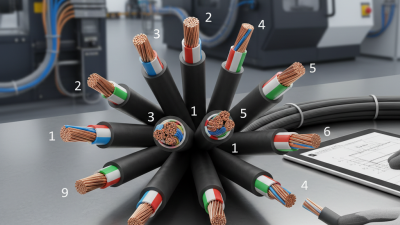

Top 10 Control Cable Types for Optimal Performance in Industrial Applications

-

Understanding Multi Conductor Cables: Essential Tips for Effective Electrical Wiring

-

Understanding Lead Cables: Essential Insights for Safe Electrical Installations

-

2025 Top 5 Industrial Electric Wire and Cable Solutions for Every Business Need

-

Essential Automotive Cable Maintenance Tips for a Smooth Ride

-

10 Essential Tips for Choosing the Right Automotive Wire for Your Needs