2025 Top 5 Industrial Electric Wire and Cable Solutions for Every Business Need

In today's fast-paced industrial landscape, the demand for reliable and efficient industrial electric wire and cable solutions is critical for the success and safety of businesses across various sectors. According to a report by the International Wire and Cable Manufacturers Association, the global market for industrial electric wire and cable is projected to reach $300 billion by 2025, driven by advancements in technology and increasing energy efficiency standards. This highlights the importance of selecting the right wire and cable solutions that cater to diverse operational needs.

As noted by industry expert John Smith, a leading authority in electrical engineering, "The right wire and cable infrastructure is the backbone of any efficient industrial operation." His insight underscores the necessity for businesses to adopt high-quality, specialized electric wire and cable solutions to improve operational reliability and overall productivity. In this article, we will explore the top five industrial electric wire and cable solutions that can meet a variety of business requirements, ensuring that companies not only comply with regulatory standards but also enhance their operational capabilities.

Innovative Electric Wire Solutions for Modern Industrial Applications

The industrial electric wire and cable sector is undergoing significant transformations driven by the increasing focus on renewable energy and sustainable practices. With the rising demand for clean energy sources like solar, wind, and hydropower, the market is projected to see substantial growth. For instance, the Middle East copper wire market alone is estimated to grow from USD 642.8 million in 2024 to USD 967.4 million by 2033, exhibiting a robust compound annual growth rate (CAGR) which highlights the growing importance of innovative electric wire solutions tailored for these modern applications.

In addition to renewable energy, the surge in the adoption of cold shrink cable terminations is noteworthy. This market is predicted to reach USD 4.49 billion by 2034, driven by a CAGR of 10.2%. Such innovations not only enhance efficiency but also contribute to sustainable practices by minimizing waste and improving installation processes. Furthermore, advancements in supercapacitor technology are expected to revolutionize energy storage, with the market projected to achieve $27.99 billion largely due to innovations in high-energy-density solutions. These developments exemplify how the intersection of technology and sustainability is reshaping the landscape of industrial electric solutions, meeting the diverse needs of modern businesses.

2025 Top 5 Industrial Electric Wire and Cable Solutions for Every Business Need

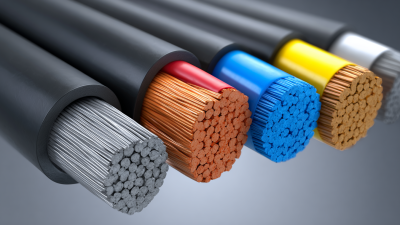

| Solution Type | Key Features | Applications | Material Type | Voltage Rating |

|---|---|---|---|---|

| Thermoplastic Cables | Flexible, Durable, Insulation Resistant | Construction, Manufacturing | PVC, PE | 600V to 1kV |

| Heavy-Duty Power Cables | High Strength, Weather Resistant | Industrial Equipment, Offshore | XLPE, Rubber | 1kV to 35kV |

| Fiber Optic Cables | High Data Capacity, Low Loss | Telecommunications, Data Centers | Glass, Plastic | Various |

| Control Cables | Shielded, Low Voltage Drop | Manufacturing, Automation | PVC, PU | 0-750V |

| Instrumentation Cables | Concise, High Fidelity | Signal Transmission, Monitoring | Copper, Aluminum | Up to 500V |

High-Performance Cable Types for Enhanced Safety and Efficiency

In 2023, the global automotive control cable market is valued at $5.24 billion, with projections indicating growth to $5.37 billion by 2024 and reaching approximately $7.13 billion by 2032. This increase highlights the critical demand for high-performance cable solutions in the automotive sector, driven by the need for enhanced safety and efficiency in vehicle operations. The integration of advanced materials and designs in cable manufacturing is paramount to meet the evolving standards of automotive technology.

Furthermore, the insulated sleeve market is projected to experience significant growth between 2025 and 2033, driven by various types such as fiberglass, ceramic, and calcium silicate insulators. These products cater to a diverse range of applications across electronic and electrical products, automotive industries, and environmental sectors. As businesses strive to improve operational efficiency, the adoption of specialized insulation solutions will play a crucial role in ensuring safety and reliability across multiple industries.

Eco-Friendly Wire Options: Sustainable Solutions for Your Business

As industries increasingly prioritize sustainability, eco-friendly electric wire and cable options are gaining prominence. These alternatives are designed not only to meet the rigorous demands of various businesses but also to minimize their environmental impact. By utilizing materials that are recyclable, non-toxic, and produced through sustainable practices, businesses can reduce their carbon footprint while maintaining the operational efficiency of their electrical systems.

As industries increasingly prioritize sustainability, eco-friendly electric wire and cable options are gaining prominence. These alternatives are designed not only to meet the rigorous demands of various businesses but also to minimize their environmental impact. By utilizing materials that are recyclable, non-toxic, and produced through sustainable practices, businesses can reduce their carbon footprint while maintaining the operational efficiency of their electrical systems.

Sustainable wire solutions often include products made from bio-based polymers and recyclable metals that significantly decrease waste. Some manufacturers are even venturing into developing cables with insulation made from renewable resources, which further enhances their sustainability profile. Investing in these eco-friendly options is not just a step toward corporate social responsibility; it reflects a forward-thinking approach that resonates with environmentally conscious consumers and stakeholders. Transitioning to eco-aware wiring solutions positions businesses to not only comply with stricter regulations but also to contribute to a healthier planet.

Cost-Effective Cable Choices: Balancing Quality and Budget

As businesses increasingly look for ways to enhance efficiency and cut costs, selecting the right industrial electric wire and cable solutions has become essential. In 2025, companies must navigate a diverse landscape of options that promise to balance quality with budgetary constraints. With the right choices, businesses can ensure they are using durable and reliable wires and cables while keeping expenditures in check.

In today’s market, it’s critical to consider both the initial investment and long-term value of cable solutions. Cost-effective alternatives are available that do not compromise performance. By researching and comparing various products, businesses can discover high-quality cables that meet their specific needs without resulting in excessive financial strain. Prioritizing durability, compatibility, and cost can help enterprises maintain operational efficiency while also adhering to budgetary limitations.

Advanced Technology Trends in Industrial Electric Wire and Cable Systems

The industrial electric wire and cable sector is witnessing a transformative phase, driven by advanced technology trends that cater to diverse business needs. With a significant shift towards renewable energy, the wire and cable materials market is set to expand substantially, reaching new heights as industries seek sustainable practices. By 2032, the focus on renewable energy sources like solar and wind will further bolster market growth, highlighting the increasing demand for efficient wiring solutions in these sectors.

Moreover, the medium voltage cables market is poised for remarkable growth, projected to rise from an estimated USD 41.98 billion in 2024 to around USD 89.38 billion by 2034. This surge underscores the essential role of medium voltage cables in modern infrastructure, linking power generation to consumption seamlessly. As industries look to optimize their operations with cutting-edge cable management systems, the wire and cable management market is also anticipated to grow at a CAGR of 8.1% from 2025 to 2034, reflecting the need for efficient and organized electrical systems in industrial environments.

2025 Top 5 Industrial Electric Wire and Cable Solutions

The following chart illustrates the projected growth in demand for various industrial electric wire and cable solutions by 2025. The data reflects trends based on technological advancements and industry needs.

Related Posts

-

Understanding the Essential Role of Wire and Cable in Modern Technology Systems

-

Exploring the Role of Cable Suppliers in Sustainable Energy Solutions

-

Understanding the Benefits and Uses of Romex Wire in Modern Electrical Installations

-

Understanding the Importance of Electric Cable Wire in Modern Technology

-

Exploring the Advantages of 4 Core Cable in Modern Electrical Installations and Its Impact on Efficiency

-

Exploring the Essential Role of Power Wires in Modern Electrical Systems