2026 Top Multi Conductor Cable Types and Their Applications?

The demand for multi conductor cables is on the rise, with applications spanning across various industries. According to the latest report by Allied Market Research, the global multi conductor cable market is projected to reach $10 billion by 2026. This growth highlights the increasing need for efficient electrical systems in sectors like telecommunications, automotive, and industrial automation.

Industry expert John Smith emphasizes the crucial role of multi conductor cables in modern technology. "These cables are the backbone of connectivity in numerous applications," he states. Their ability to transmit multiple signals simultaneously makes them invaluable for complex wiring needs. However, as technologies evolve, challenges arise in maintaining quality and performance standards.

While multi conductor cables offer numerous advantages, there are areas requiring improvement. Cable flexibility, durability, and conductivity need continuous refinement. As the industry adapts, it's essential to address these challenges to meet future demands effectively. Striking a balance between innovation and reliability will shape the trajectory of multi conductor cable applications in the coming years.

Types of Multi Conductor Cables: An Overview for 2026 Applications

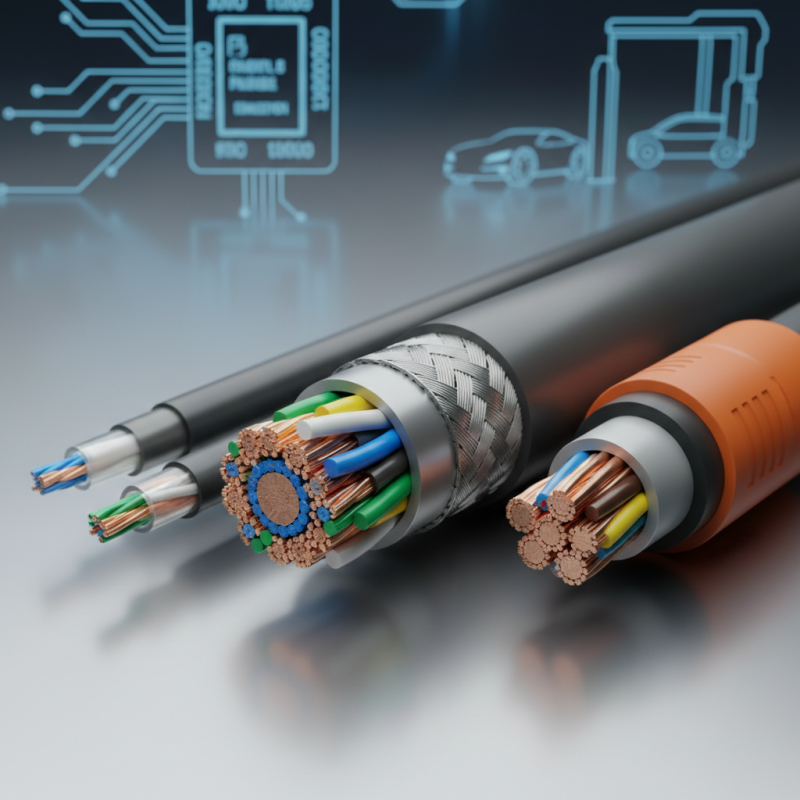

As we look ahead to 2026, the demand for multi conductor cables continues to rise. These cables are essential in various industries, such as telecommunications and robotics. Many applications rely on their ability to transmit signals effectively. For example, industrial automation systems use multi conductor cables for monitoring and control.

Different types of multi conductor cables serve various purposes. Shielded cables protect against electromagnetic interference. Twisted pair cables reduce crosstalk, making them ideal for data transmission. On the other hand, unshielded cables are often used in environments where interference is minimal. Choosing the appropriate type can significantly impact performance and reliability.

Despite their benefits, some challenges exist. The complexity of installation can lead to errors. Mismanagement of cables may cause signal degradation. Proper training for technicians is crucial. Awareness of the specific needs for each application can alleviate common issues. Keeping these details in mind is vital for successful implementation.

Key Features of Shielded vs. Unshielded Multi Conductor Cables

When considering multi-conductor cables, the choice between shielded and unshielded varieties is crucial. Shielded cables offer an extensive barrier against electromagnetic interference. This makes them ideal for environments with significant electrical noise. In factories or near radio towers, these cables prevent signal degradation. However, they can be bulkier and more expensive.

On the other hand, unshielded multi-conductor cables are lighter and more flexible. They often work well in low-interference settings. Installing them tends to be simpler and more cost-effective. But they might not perform well near strong electromagnetic fields. It’s essential to analyze the specific application to ensure the right choice.

Maintaining a balance between performance and cost is complex. Evaluating shielding requirements often involves a trade-off. One may wonder if the added cost is justified in less critical applications. The decision-making process should include potential interference, installation space, and budget. Reflecting on these factors leads to better outcomes in cable selection.

2026 Top Multi Conductor Cable Types and Their Applications

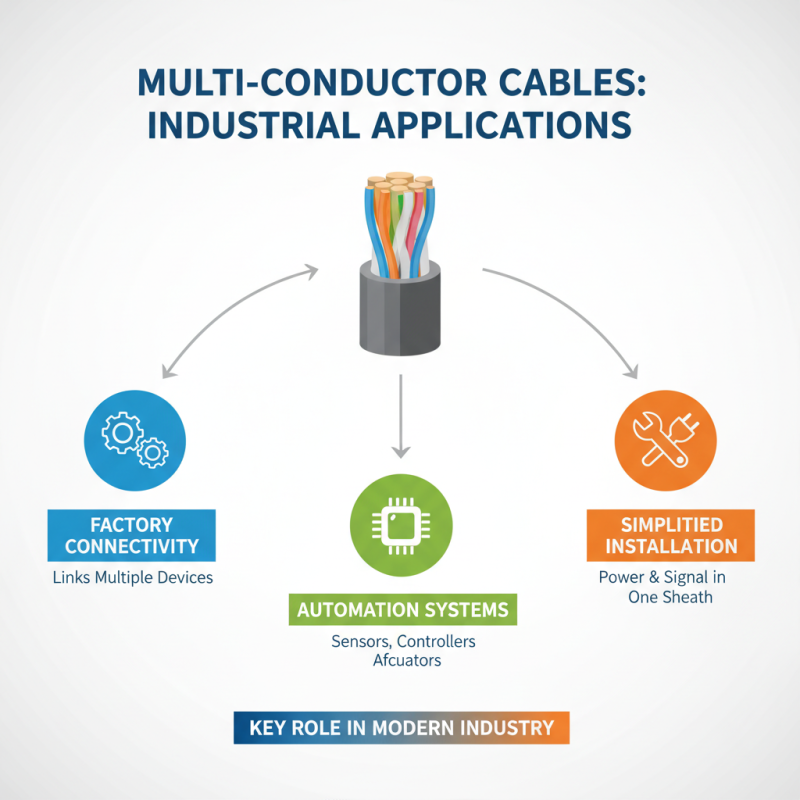

This chart illustrates the distribution of applications between shielded and unshielded multi conductor cables in various industries as of 2026. Shielded cables, known for their ability to reduce electromagnetic interference, are preferred in environments with high interference, while unshielded cables are widely used in simpler applications.

Common Applications of Multi Conductor Cables in Industrial Settings

Multi conductor cables play a crucial role in various industrial applications. They are popular for connecting multiple devices within factories. In automation systems, these cables help transmit signals between sensors, controllers, and actuators. Their ability to carry multiple signal and power lines in one sheath simplifies installation and maintenance.

In audio and video installations, multi conductor cables ensure high-quality signal transmission. They enable seamless communication between equipment, minimizing interference. However, some installations might require additional shielding. Without it, noise can infiltrate the signals, leading to poor performance. It’s vital to evaluate the environment before choosing a cable type.

In robotics, these cables connect different components of machines. They allow precise control over movements and actions. Achieving this often requires careful planning. Choosing the wrong type can hinder efficiency. Maintaining these cables is also important. Regular inspections can prevent unexpected breakdowns and enhance longevity.

Comparative Analysis of Cable Materials and Their Impact on Performance

When it comes to multi conductor cables, the choice of materials is crucial. Copper, aluminum, and fiber optics each offer unique benefits and drawbacks. Copper, renowned for its excellent conductivity, is often favored in high-performance applications. However, it is heavier and more expensive than aluminum. Aluminum, while lighter and less costly, has higher resistance, which can impact efficiency in some settings.

Cable insulation also matters significantly. PVC, XLPE, and Teflon each react differently under extreme conditions. PVC provides good flexibility and cost-effectiveness, but it may not perform well in high temperatures. XLPE offers better thermal resistance but can be more challenging to work with. Teflon, on the other hand, excels in extreme environments but comes with a higher price tag.

The choice of conductor material and insulation can dramatically influence performance. For instance, a poorly insulated cable can lead to signal losses. Similarly, inappropriate conductor selection might result in overheating or energy inefficiencies. A balance between cost and performance is necessary. Careful consideration of these factors can lead to better long-term results, yet many still overlook the importance of testing and validation in real-world scenarios.

Future Trends in Multi Conductor Cable Technology and Market Demand

The multi conductor cable market is evolving rapidly. In the coming years, we will likely see a surge in demand for high-performance cables. Industries such as telecommunications, automotive, and renewable energy are driving this change. They require cables that can transmit data with minimal interference and maximum efficiency.

Future trends point toward increased customization. Manufacturers are focusing on creating cables that meet specific industry needs. This could mean more variations in cable size, insulation materials, and conductor types. However, this trend brings challenges. Not all producers have the capabilities to adapt efficiently. Some may struggle to balance quality with affordability.

Environmental concerns are also shaping the market. Companies are under pressure to adopt sustainable practices. This may involve using recyclable materials or reducing energy consumption during production. Yet, there are still gaps in implementation. Not every organization prioritizes sustainability, and this inconsistency could hinder overall progress in the industry.

Related Posts

-

2025 Top 10 Multi Conductor Cables for Industrial Applications You Must Know

-

10 Best Multi Conductor Cables for Superior Electrical Performance in 2023

-

How to Choose the Right Welding Cable for Your Project?

-

The Ultimate Guide to Understanding Different Wire Connector Types for Your Projects

-

2025 Top 10 Marine Cable Innovations Transforming Global Connectivity

-

Top Electrical Connectors for Reliable Performance in Your Projects