2026 Top Electrical Wire Connectors for Every Project Need?

In 2026, the demand for reliable electrical wire connectors is increasingly crucial for various projects. According to industry reports, the global electrical connectors market is projected to grow significantly, reaching $80 billion by 2027. This surge highlights the importance of choosing the right connectors for electrical systems.

Electrical wire connectors play a vital role in ensuring safe and efficient connections. They are essential in residential, commercial, and industrial applications. Misalignment or subpar connectors can lead to serious failures, resulting in costly repairs. Statistics show that 40% of electrical issues stem from poor connections.

Selecting high-quality electrical wire connectors is not merely a choice; it’s a necessity. Many projects overlook this aspect. Individuals often focus on aesthetics or other components. However, the integrity of the entire system relies heavily on these small yet critical components. Upgrading to durable connectors can enhance safety and longevity. It's worth evaluating the available options carefully to avoid potential setbacks.

Understanding Electrical Wire Connectors and Their Types

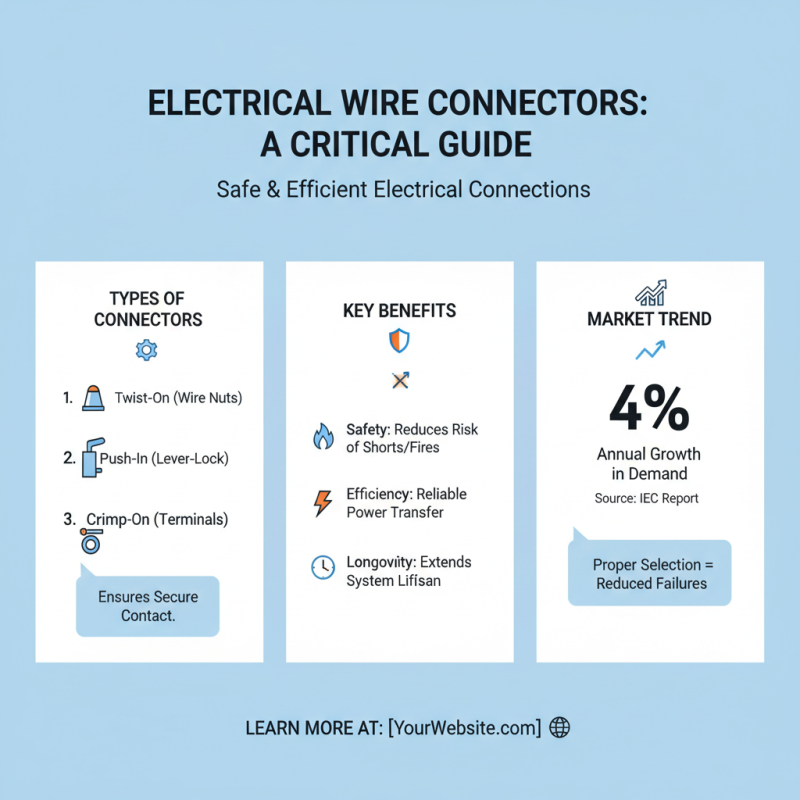

When dealing with electrical wire connectors, it's essential to understand the various types available. Connectors serve crucial roles in ensuring safe and efficient electrical connections. According to a report by the International Electrotechnical Commission, the demand for reliable electrical connections is projected to grow by 4% annually. Proper selection and use of connectors can reduce the risk of failures and increase the lifespan of electrical systems.

There are several types of wire connectors, such as twist-on, crimp, and push-in connectors. Each type has its advantages and disadvantages. For instance, twist-on connectors are easy to use but may loosen over time. Crimp connectors provide a strong connection but require specific tools for installation. Understanding these details is crucial for any project.

Tips: Always choose connectors that match your wire gauge. This ensures proper electrical flow. Regularly inspect connections for wear or corrosion. A small oversight can lead to significant problems down the line. Remember, ensuring code compliance is vital. Neglecting this can result in safety hazards. Prioritize quality over convenience in your selections.

Key Factors to Consider When Choosing Electrical Wire Connectors

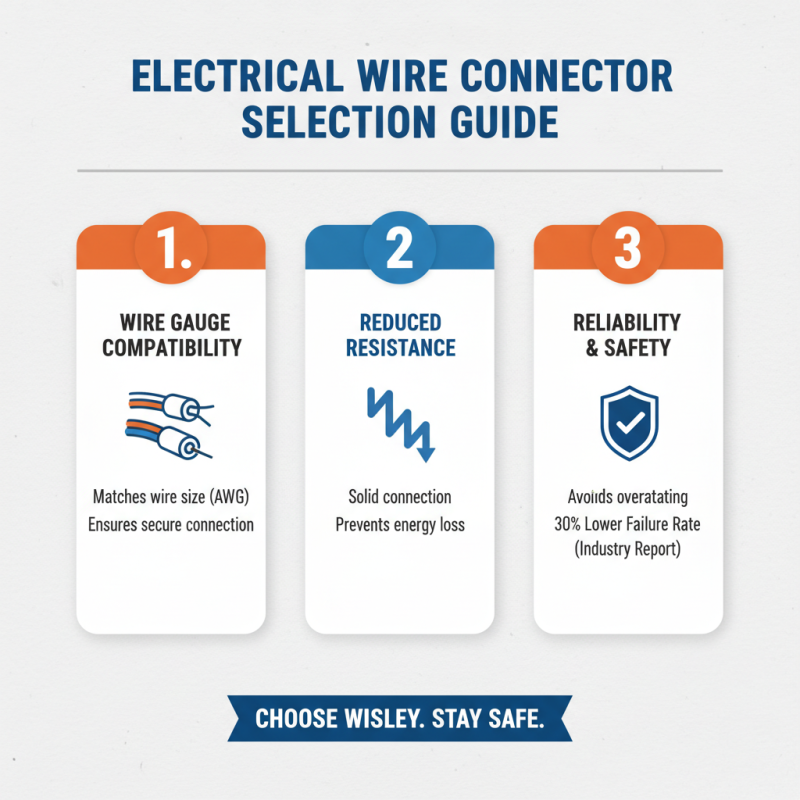

When selecting electrical wire connectors, several key factors should be considered. Compatibility with wire gauge is crucial. Using connectors that fit the wire size ensures a solid connection, reducing resistance and potential overheating. Industry reports indicate that improper sizing can lead to a 30% increase in failure rates over time.

Material quality is another essential aspect. Connectors made from high-quality metals, such as copper or brass, provide better conductivity. Lack of proper material can result in poor connectivity, leading to equipment malfunction. According to recent studies, connectors with lower-grade materials face corrosion issues within just a couple of years.

Lastly, environmental factors play a role. Connectors must withstand the project's conditions, such as temperature and humidity. For instance, connectors used in outdoor settings need moisture resistance. Research shows that more than 25% of electrical failures are attributed to environmental damage. Always assess the specific needs of your project carefully. Ignoring these factors may lead to costly repairs or safety hazards down the line.

Top Electrical Wire Connectors for Residential Projects

When choosing electrical wire connectors for residential projects, quality and compatibility are key. These connectors facilitate secure and efficient connections. Popular types include twist-on, crimp, and push-in connectors. Each type serves specific purposes, making it crucial to select the right one for your project.

In residential settings, the installation may not always be perfect. For example, using the wrong connector can lead to overheating or sparks. It's essential to check wire gauge and connector type before installation. Consider using connectors that are easy to manage but also durable. Comfort in handling can significantly impact your project's outcome.

Remember, not every project goes as planned. Sometimes, connectors might not hold as expected, requiring re-evaluation. Mistakes happen, and they can teach valuable lessons. Always have a backup plan, ensuring you can switch connectors when issues arise. A well-thought-out approach can enhance safety and reliability in electrical installations.

2026 Top Electrical Wire Connectors for Every Project Need

| Connector Type | Material | Current Rating (Amps) | Temperature Rating (°C) | Applications |

|---|---|---|---|---|

| Butt Connector | Copper | 22 | 105 | General wiring |

| Ring Terminal | Copper | 30 | 105 | Battery connections |

| Splice Connector | Aluminum | 40 | 90 | Outdoor wiring |

| Wire Nut | Plastic | 15 | 75 | Indoor wiring |

| Plug Connector | Copper | 20 | 100 | Portable devices |

Best Electrical Wire Connectors for Commercial Applications

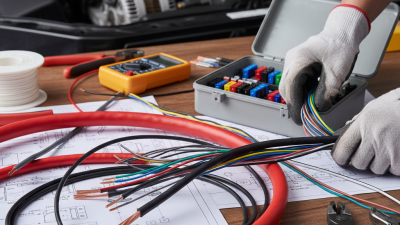

When selecting electrical wire connectors for commercial applications, it's essential to understand the specific needs of your project. High-quality connectors ensure reliability in various environments. Many commercial projects involve heavy machinery and high voltage. This means you need connectors that can withstand wear and frequent use.

Consider connectors made from durable materials. They should resist corrosion, which can occur in industrial settings. Look for options that are easy to install. In some cases, complicated connectors can lead to errors during installation. This can result in safety hazards, which is unacceptable. Additionally, remember that not all connectors are suitable for every application. Research is key to finding the right match for your needs.

Another point to think about is the connector's capacity. It's crucial to choose connectors that can handle the required current load. Overloading a connector can cause failures and downtime. While it may be tempting to cut costs, investing in reliable connectors pays off. Regular maintenance checks are also necessary. It ensures that all connectors function properly and safely.

Innovative Electrical Wire Connectors for Automotive and Industrial Use

Innovative electrical wire connectors play a crucial role in both automotive and industrial applications. These connectors must withstand various environmental conditions. High temperatures, moisture, and vibration are common challenges. A connector's design needs to be robust yet user-friendly. A well-engineered connector can significantly enhance performance and safety in vehicles and machinery.

Some wire connectors can fail under stress, leading to costly repairs. Many users overlook details like corrosion resistance and contact points. A simple oversight could mean the difference between reliability and malfunction. Keeping these factors in mind can improve connections and ensure longevity. In industrial setups, connectors must also support heavy-duty uses without compromising efficiency.

As technology evolves, lighting, sensors, and electric vehicles demand even more from connectors. Innovation is key to meeting these challenges. Engineers must understand the nuances of connector types and applications. Without this knowledge, projects might face setbacks. The search for better solutions continues in this ever-changing landscape.

2026 Top Electrical Wire Connectors for Every Project Need

Related Posts

-

Essential Automotive Cable Maintenance Tips for a Smooth Ride

-

Top Electrical Connectors for Reliable Performance in Your Projects

-

10 Essential Tips for Choosing the Right Automotive Wire for Your Needs

-

Why Are Electrical Connectors Essential for Reliable Electrical Connections?

-

Understanding the Importance of Electric Cable Wire in Modern Technology

-

Top Benefits of Using Lead Cable for Your Electrical Projects