Exploring the Advantages of 4 Core Cable in Modern Electrical Installations and Its Impact on Efficiency

In recent years, the demand for efficient and reliable electrical installations has surged, prompting professionals to explore advanced solutions such as 4 core cable systems. According to a report by MarketsandMarkets, the global market for electrical wiring is projected to reach $214.5 billion by 2025, with the adoption of multi-core cables increasing across various sectors. The versatility and improved performance of 4 core cable, which typically consists of three phase conductors and one neutral, greatly enhance circuit efficiency and safety. This configuration not only simplifies wiring but also reduces installation time and material costs, thereby optimizing overall project budgets. Furthermore, data from the International Energy Agency (IEA) indicates that leveraging more efficient electrical systems can lead to significant energy savings, underscoring the importance of integrating technologies like 4 core cable in modern electrical frameworks. Exploring its advantages reveals how such innovations can transform the industry while adhering to both economic and environmental standards.

The Role of 4 Core Cable in Reducing Energy Loss in Electrical Systems

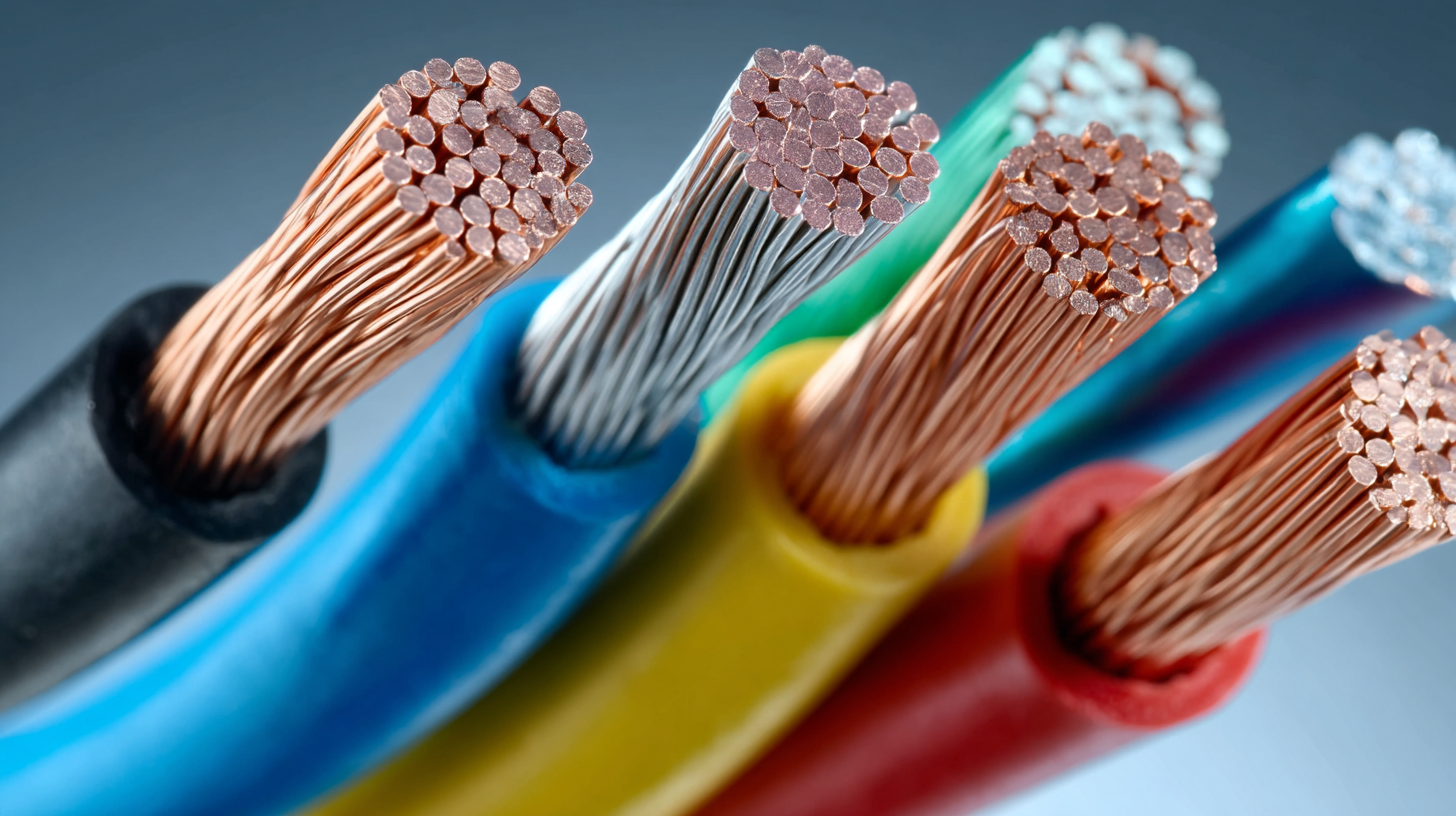

The role of 4 core cable in reducing energy loss in electrical systems is increasingly significant, particularly in the context of modern electrical installations aimed at enhancing efficiency. Traditional wiring systems often contribute to energy inefficiencies that can waste substantial resources, with studies indicating that around 5% of global GDP is lost annually due to such inefficiencies. The adoption of 4 core cables mitigates some of these losses through optimized energy distribution, allowing for smoother operation and reduced resistance in electrical systems.

Incorporating 4 core cable into integrated energy systems is not only beneficial for performance but also aligns with the broader goals of energy efficiency and sustainability. As clean energy transitions gain momentum, the efficiency offered by advanced cabling solutions supports efforts to minimize carbon emissions, making it a critical component in the quest for lower-carbon energy systems. This aligns with recent initiatives focusing on optimizing infrastructure to decrease overall energy consumption and waste, establishing 4 core cable as an integral part of the future of efficient electrical installations.

Key Advantages of Utilizing 4 Core Cable for Enhanced Load Balancing

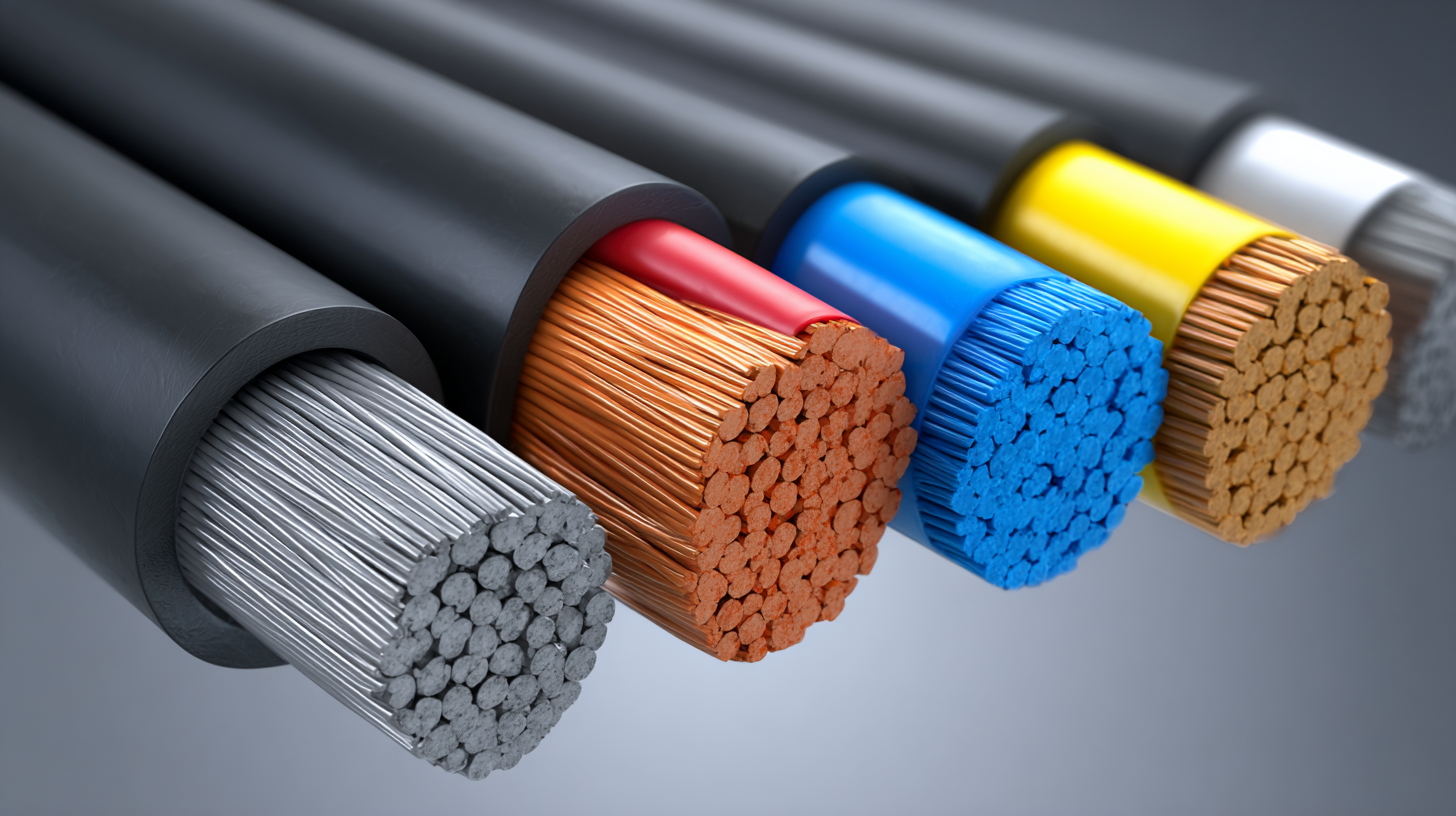

In modern electrical installations, utilizing 4 core cable has become increasingly popular due to its multifaceted advantages, especially in load balancing. A 4 core cable typically comprises four individual conductors, which enhances the ability to distribute electrical loads more evenly across circuits. This not only helps avoid overloading any single conductor but also improves overall efficiency while reducing energy losses. An evenly balanced load is crucial for maintaining system stability and prolonging the lifespan of electrical components.

Tips: When installing 4 core cables, ensure that you carefully analyze your load requirements to select the appropriate cable size. This prevents future complications and ensures maximum efficiency.

Furthermore, the design of 4 core cables allows for the easy management of phase and neutral connections, facilitating smoother operation in three-phase systems. By leveraging the fourth core, electricians can implement additional features such as earth connections or control circuits seamlessly. This flexibility is vital, particularly in industrial settings where machinery and systems require refined control over power distribution.

Tips: Regularly monitor your electrical systems and conduct periodic maintenance checks. Identifying imbalances early can help mitigate potential downtime and enhance the performance of your installations.

Comparative Analysis: 4 Core Cable vs. Traditional Wiring Solutions

In the evolving landscape of electrical installations, comparing 4 core cables to traditional wiring solutions reveals significant advantages that enhance system efficiency. According to the International Electrotechnical Commission (IEC), 4 core cables are designed to carry four separate circuits, allowing for more streamlined connections and reduced installation time. This not only minimizes labor costs but also maximizes the space efficiency within conduits, as fewer cables are required to achieve the same functionality as multiple traditional wires.

Moreover, a report by the Institute of Electrical Engineers indicates that 4 core cables demonstrate improved electrical performance and safety features. For instance, these cables can better handle overload conditions due to their capacity to distribute electrical loads more evenly. Traditional wiring solutions, often limited to two or three cores, can lead to excessive heat generation and increased wear over time. With a reported 30% increase in efficiency and a lower risk of circuit failure, adopting 4 core cables in modern installations is becoming a trend that aligns with both safety and cost-effectiveness in large-scale electrical projects.

Exploring the Advantages of 4 Core Cable in Modern Electrical Installations and Its Impact on Efficiency - Comparative Analysis: 4 Core Cable vs. Traditional Wiring Solutions

| Feature | 4 Core Cable | Traditional Wiring |

|---|---|---|

| Voltage Rating | Up to 600/1000V | Up to 600/1000V |

| Conductivity | Higher conductivity due to multiple cores | Lower conductivity with single-phase wiring |

| Installation Flexibility | Easy to route; adaptable for complex installations | Less flexible, limited in complex settings |

| Efficiency | Improved energy efficiency | Less energy efficient |

| Installation Cost | Higher initial cost but long-term savings | Lower initial cost but higher maintenance |

| Safety | Better protection against short circuits | Higher risk of overheating |

| Maintenance | Lower maintenance requirements | Higher maintenance frequency |

Impact of 4 Core Cable on System Reliability and Maintenance Efficiency

The use of 4 core cables in modern electrical installations significantly enhances system reliability and maintenance efficiency. One of the primary advantages of these cables is their ability to transmit multiple electrical functions within a single unit. This not only reduces clutter in installations but also minimizes the risk of potential faults that can arise from having several individual cables. By consolidating the wiring into one cable, the chances of loose connections or damaged wires, which often lead to system inefficiencies, are noticeably reduced.

Furthermore, the simplified structure of 4 core cables allows for easier inspection and maintenance. Technicians can quickly identify issues without having to navigate through a complex web of wires. This streamlined approach leads to quicker diagnostic times and less downtime for systems, improving overall operational efficiency. Overall, the adoption of 4 core cable technology is an investment in both reliability and cost-effectiveness, as it simplifies maintenance protocols and enhances the longevity of electrical installations.

Industry Trends: Adoption Rates of 4 Core Cable in New Electrical Installations

The adoption rates of 4 core cable in new electrical installations have seen a significant increase as industry demands evolve. With the global electrical equipment market projected to grow from $1,660.20 billion in 2025 to $3,326.86 billion by 2032, at a CAGR of 10.4%, it is essential for organizations to consider efficient solutions like 4 core cable. This type of cable not only provides enhanced electrical performance but also minimizes the need for additional wiring, streamlining installation processes and reducing costs in the long run.

The adoption rates of 4 core cable in new electrical installations have seen a significant increase as industry demands evolve. With the global electrical equipment market projected to grow from $1,660.20 billion in 2025 to $3,326.86 billion by 2032, at a CAGR of 10.4%, it is essential for organizations to consider efficient solutions like 4 core cable. This type of cable not only provides enhanced electrical performance but also minimizes the need for additional wiring, streamlining installation processes and reducing costs in the long run.

Moreover, industry trends indicate that more manufacturers are recommending 4 core cables due to their improved capacity for power distribution and reduced energy losses. As businesses prioritize sustainability and efficiency, adopting 4 core cables can significantly impact operational effectiveness.

Tips: When considering a switch to 4 core cables, ensure compatibility with existing systems. Additionally, consult with professionals specializing in electrical installations to determine the most suitable options for your specific needs. Emphasizing proper installation techniques can further enhance performance and safety in your electrical systems.

Related Posts

-

Understanding the Benefits and Uses of Romex Wire in Modern Electrical Installations

-

The Ultimate Guide to Understanding Different Wire Connector Types for Your Projects

-

Exploring the Essential Role of Power Wires in Modern Electrical Systems

-

Understanding Multi Conductor Cables: Essential Tips for Effective Electrical Wiring