Understanding the Benefits and Uses of Romex Wire in Modern Electrical Installations

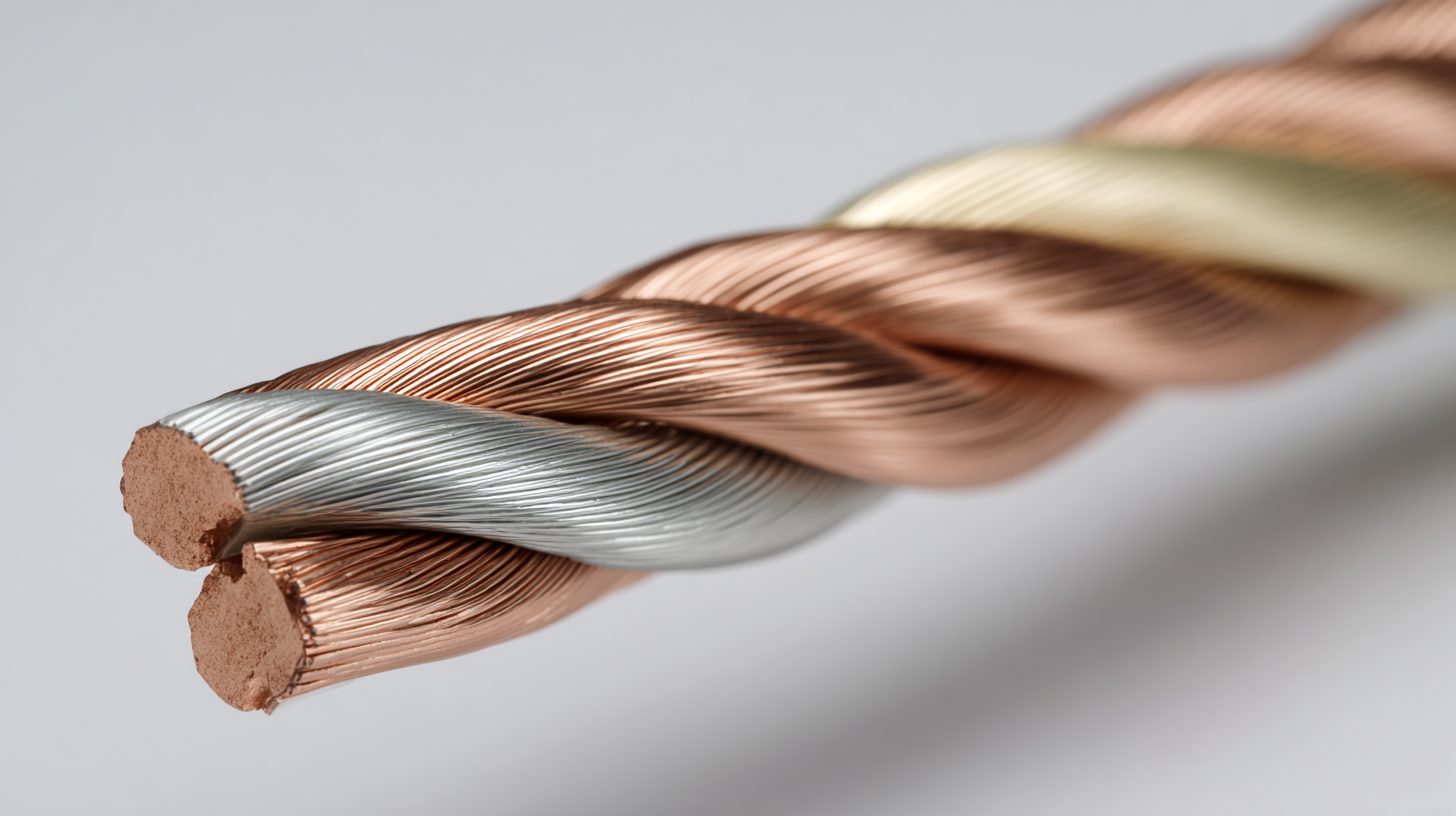

In the realm of modern electrical installations, Romex wire has emerged as a widely utilized solution due to its versatility and efficiency. According to industry reports, approximately 70% of residential electrical wiring in the United States is done using non-metallic sheathed cable, commonly known as Romex wire. This type of wire not only simplifies the installation process but also enhances safety and compliance with electrical codes. Its construction typically combines insulated conductors within a durable sheath, effectively protecting against physical damage and moisture. Furthermore, Romex wire's lightweight and flexible design allows electricians to maneuver it easily within walls and ceilings, making it an ideal choice for both new constructions and renovations. Given its significant role in the electrical supply chain, understanding the benefits and applications of Romex wire is essential for professionals aiming to optimize installation practices and adhere to safety standards.

How to Choose the Right Type of Romex Wire for Your Electrical Project

When selecting the right type of Romex wire for your electrical project, several factors must be considered to ensure safety and efficiency. Firstly, it is essential to determine the appropriate gauge of wire based on the current load requirements of your installation. Romex wire is available in various gauges, typically ranging from 14 to 6, with lower numbers indicating thicker wire capable of handling higher currents. For residential wiring, 14-gauge wire is commonly used for lighting circuits, while 12-gauge is standard for general outlets. Assessing the wattage of the devices to be connected will guide this choice.

Another critical consideration is the type of Romex wire insulation needed for your specific environment. Different types of Romex wire, such as NM-B (non-metallic sheathed cable), are designed for indoor use and offer good protection against moisture and heat. If your project involves outdoor installations or areas prone to dampness, you might want to opt for UF (underground feeder) cable, which provides added durability and resistance to environmental hazards. Always ensure that the selected wire complies with local electrical codes and standards, which help safeguard your project against potential hazards.

Understanding the Benefits and Uses of Romex Wire in Modern Electrical Installations

| Wire Type | Application | Ampacity | Insulation Type | Typical Uses |

|---|---|---|---|---|

| 14/2 | Lighting Circuits | 15 Amps | NM-B | Residential Lighting |

| 12/2 | General Circuits | 20 Amps | NM-B | Outlets and Appliances |

| 10/2 | Heavy Duty Circuits | 30 Amps | NM-B | Hot Tubs, Large Appliances |

| 14/3 | Multi-Way Switching | 15 Amps | NM-B | Three-way and Four-way Switches |

How to Properly Install Romex Wire in Walls and Ceilings

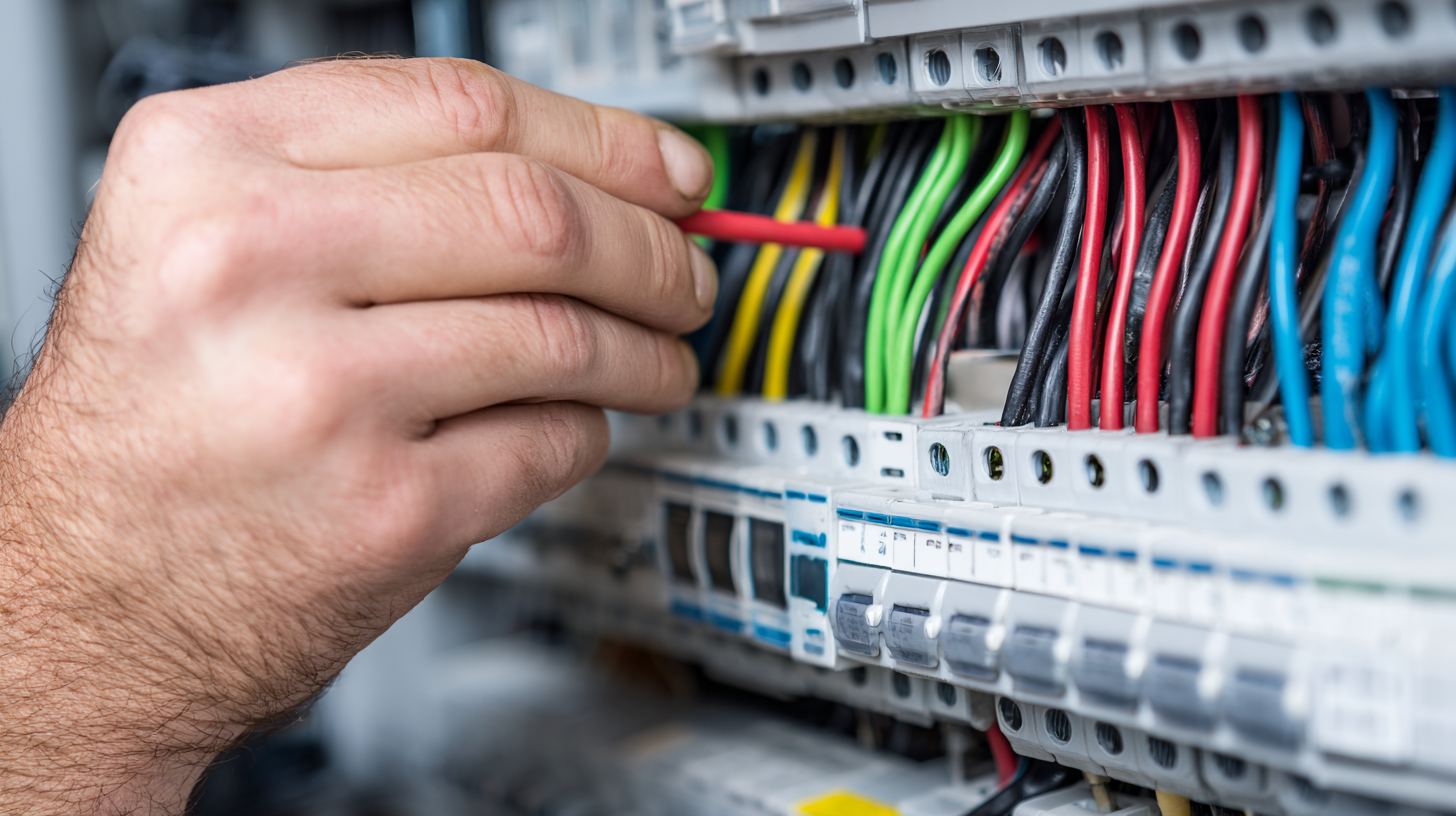

When it comes to modern electrical installations, Romex wire, commonly known as NM (non-metallic) cable, is favored for its flexibility and ease of installation. Properly installing Romex wire in walls and ceilings is essential for ensuring safety and function. Begin by planning the layout of your electrical system, including the locations of outlets, switches, and lighting fixtures. Mark these spots on the wall, as this will guide your wire run.

**Tips:** Always ensure that the Romex wire is rated for the appropriate amperage for your circuit. Use wire staples to secure the cable to wall studs and ceilings, avoiding sharp bends that could damage the insulation. Maintain a distance of at least 1.25 inches from edges of framing members to prevent accidental nailing or drilling that could expose the wire.

When running Romex wire between floors or through ceilings, make sure it's tucked neatly in place and supported appropriately according to local codes. Pull the wire gently without exceeding its recommended bend radius, and avoid over-bundling cables to minimize the risk of overheating. This careful approach will lead to a safe and effective electrical installation.

Understanding the Uses of Romex Wire in Electrical Installations

How to Ensure Safety and Compliance When Using Romex Wire

When working with Romex wire in modern electrical installations, safety and compliance should be paramount. One of the key aspects to consider is ensuring that your wiring conforms to local codes and regulations. It’s essential to familiarize yourself with the National Electrical Code (NEC) requirements as well as any specific local amendments that may apply. Adhering to these guidelines will not only keep you compliant but also enhance the safety of your electrical systems.

Tips: Always double-check the wiring configurations and ensure you're using the correct gauge of Romex wire for your specific load requirements. Proper installation techniques, such as securing the wire appropriately within walls and avoiding any unnecessary bends, can help prevent potential hazards. Additionally, consider using circuit breakers that are rated for the Romex wire to ensure maximum protection.

Furthermore, remember to conduct routine inspections of your electrical installations. This can help identify any potential issues early on, such as frayed wires or loose connections, reducing the risk of electrical fires or other hazards. Regular maintenance and prompt attention to any irregularities will ensure a safe and compliant electrical system using Romex wire.

How to Troubleshoot Common Issues with Romex Wiring

When dealing with Romex wiring in modern electrical installations, understanding how to troubleshoot common issues is vital for ensuring safety and efficiency. One frequent problem is a loose connection, which can lead to increased resistance and heat generation, potentially causing a fire hazard. According to the National Fire Protection Association (NFPA), electrical distribution systems, including wiring, are responsible for approximately 15% of structure fires in the United States. This statistic underscores the importance of properly securing connections to prevent fires.

When dealing with Romex wiring in modern electrical installations, understanding how to troubleshoot common issues is vital for ensuring safety and efficiency. One frequent problem is a loose connection, which can lead to increased resistance and heat generation, potentially causing a fire hazard. According to the National Fire Protection Association (NFPA), electrical distribution systems, including wiring, are responsible for approximately 15% of structure fires in the United States. This statistic underscores the importance of properly securing connections to prevent fires.

Tip: Always ensure that wire connections are tight and free from corrosion. Regularly inspect outlet boxes and junctions for any signs of wear or damage.

Another common issue is the interference from external electrical devices, which can create fluctuating power supply and lead to voltage drops. A study by the Institute of Electrical and Electronics Engineers (IEEE) highlights that voltage fluctuations can cause sensitive equipment to malfunction or degrade faster. Learning to identify these issues early can save time and reduce repair costs.

Tip: Use a multimeter to regularly check voltage levels throughout your electrical system and identify any inconsistent readings. Proper monitoring can highlight problem areas before they evolve into larger issues.

How to Maintain and Inspect Romex Wiring for Long-Term Reliability

Maintaining and inspecting Romex wiring is essential for ensuring its long-term reliability in electrical installations. Regular inspections should begin with visual checks, looking for signs of wear, fraying, or damage. Homeowners should be vigilant about checking connections, as loose or corroded terminals can lead to overheating or electrical failures. Furthermore, ensuring that the Romex is installed correctly, without sharp bends or excessive tension, minimizes the risk of damage over time.

In addition to visual inspections, it is advisable to periodically test the circuit using a multimeter or voltage tester. This helps identify any underlying issues that may not be immediately obvious. If any irregularities are detected during testing or inspection, it is critical to address them promptly, either by consulting a professional electrician or replacing damaged wiring. This proactive approach not only enhances the safety of the electrical system but also extends the lifespan of the Romex wiring, ensuring that modern electrical installations remain reliable and efficient for years to come.