Top 10 Benefits of Using Soow Cable for Your Electrical Wiring Needs

When it comes to electrical wiring needs, choosing the right type of cable can significantly impact the efficiency and safety of your projects. One of the most versatile and reliable options available in the market today is the soow cable. Designed for a variety of applications, this heavy-duty cable excels in various environments, making it an ideal choice for both residential and commercial purposes.

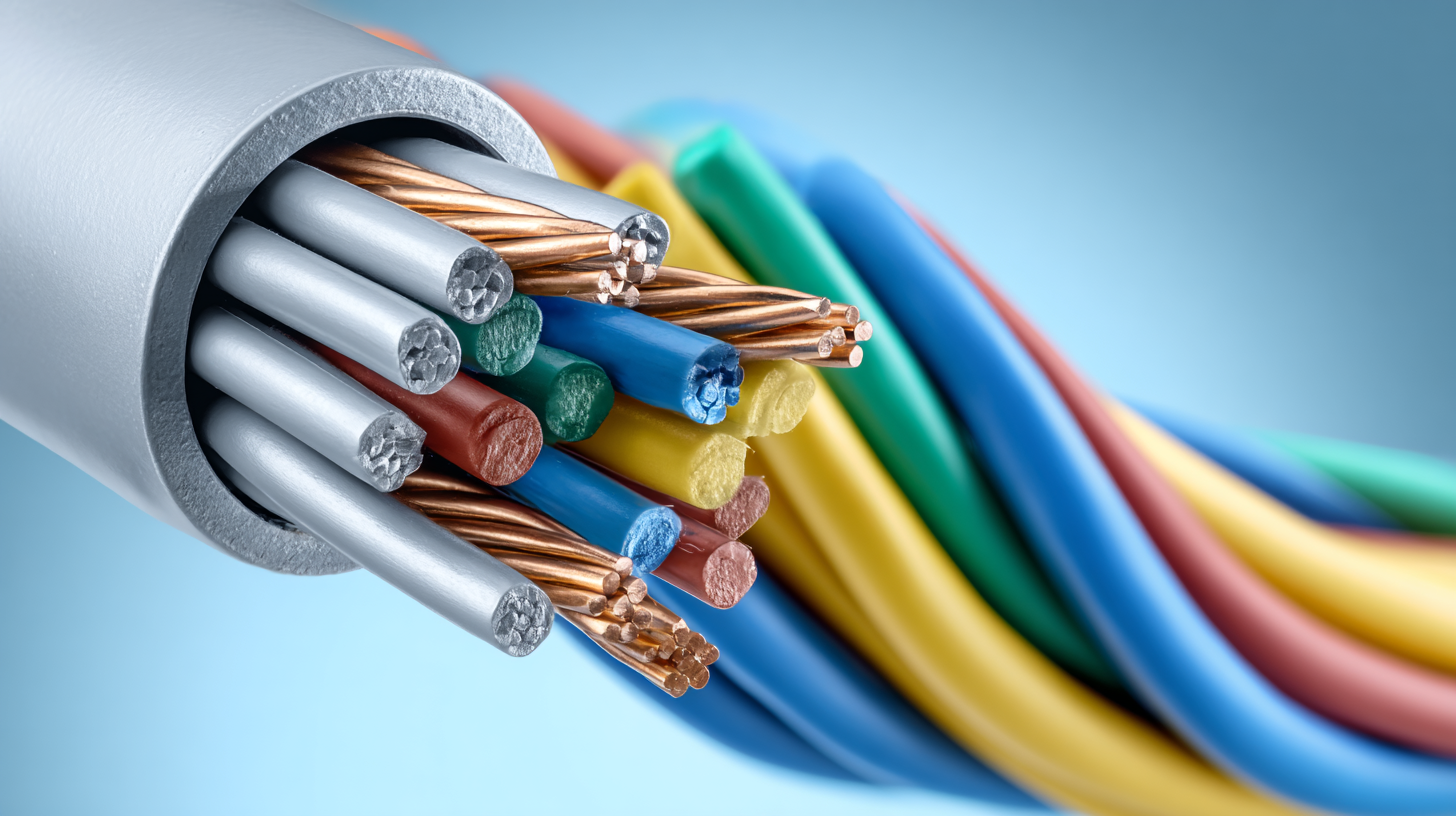

The soow cable features a robust construction that offers excellent resistance to moisture, oil, and physical wear. Whether you are working in construction, manufacturing, or even in a marine setting, using soow cable can enhance the durability and performance of your electrical systems. Additionally, its flexibility allows for easy installation in tight spaces, further contributing to its growing popularity among electricians and contractors.

In this article, we will explore the top 10 benefits of using soow cable for your electrical wiring needs. From enhanced safety features to its ability to withstand harsh conditions, understanding the advantages of soow cable will help you make informed decisions for your electrical projects.

The Superior Durability of Soow Cable for Harsh Environments

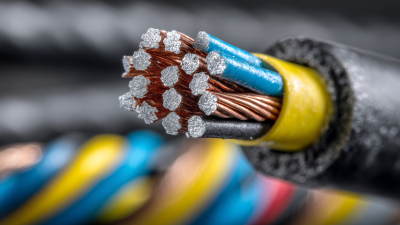

When it comes to wiring in harsh environments, the Soow cable stands out for its remarkable durability. Designed to withstand extreme temperatures, moisture, and physical abrasion, this cable is ideal for both indoor and outdoor applications. Its robust construction, featuring rubber insulation and a flexible design, allows it to perform reliably in demanding conditions. Whether you are dealing with heavy machinery in a factory or setting up temporary power on a construction site, Soow cables provide the resilience needed to ensure safe and effective operation.

**Tips:** When selecting Soow cable, consider the specific environmental factors it will encounter. Ensure it meets the necessary specifications for temperature ratings and flexibility requirements. Additionally, investing in quality connectors and protective sheathing can further enhance the longevity and performance of your wiring setup.

Moreover, the versatility of the Soow cable makes it suitable for a wide range of applications, from industrial machinery to portable power cords. Its resistance to oil, chemicals, and UV rays makes it an excellent choice for outdoor installations, ensuring it won’t easily degrade over time. When properly maintained, Soow cables can help you avoid costly downtimes and replacements due to wear and tear.

**Tips:** Regularly inspect your Soow cables for signs of damage or wear, especially if they are frequently exposed to wet or hazardous conditions. Implementing a routine maintenance schedule can help prolong the lifespan of your electrical wiring and ensure optimal performance.

| Benefit | Description | Durability Rating |

|---|---|---|

| Superior Weather Resistance | Soow cables can withstand extreme weather conditions, making them ideal for outdoor applications. | High |

| Flexibility | These cables are highly flexible, allowing for easy installation in challenging environments. | Medium |

| Oil Resistance | Soow cables are designed to resist oil and grease, ensuring performance in industrial settings. | High |

| Voltage Rating | They are suitable for a variety of voltage ratings, providing versatility for different applications. | Variable |

| Temperature Resistance | Designed to operate in high and low temperatures, making them ideal for harsh environments. | High |

| Safety | Soow cables are often made with materials that comply with safety standards, reducing fire and electric shock risks. | High |

| Cost-Effective | The longevity and durability of Soow cables can lead to lower lifecycle costs compared to other types. | Medium |

| Ease of Repair | If damaged, repairs can be made easily, allowing for minimal downtime in equipment. | High |

| Lightweight | Soow cables are lighter than other heavy-duty cables, making transportation and installation easier. | Medium |

| High Conductivity | Manufactured to offer high conductivity, ensuring efficient energy transmission. | High |

Enhanced Flexibility: A Key Advantage of Soow Cable in Wiring

Soow cable is renowned for its flexibility, making it an excellent choice for various electrical wiring needs. This characteristic is particularly beneficial in environments where cables must be maneuvered around tight corners or other obstacles. Unlike traditional rigid cables, Soow cable can be easily bent and twisted, which simplifies installation processes and reduces the risk of damage during handling. This versatility is ideal for both indoor and outdoor applications, where conditions may change or require frequent adjustments.

Moreover, the enhanced flexibility of Soow cable does not compromise its durability. It is constructed to withstand harsh environmental conditions, including exposure to moisture, extreme temperatures, and abrasion. This combination of flexibility and robustness ensures that the cable can perform reliably over a long lifespan, even in challenging settings such as construction sites or industrial operations. With its ability to bend and flex while remaining durable, Soow cable is not only a practical solution but also a smart investment for various wiring projects.

Increased Safety Features of Soow Cable Compared to Traditional Wiring

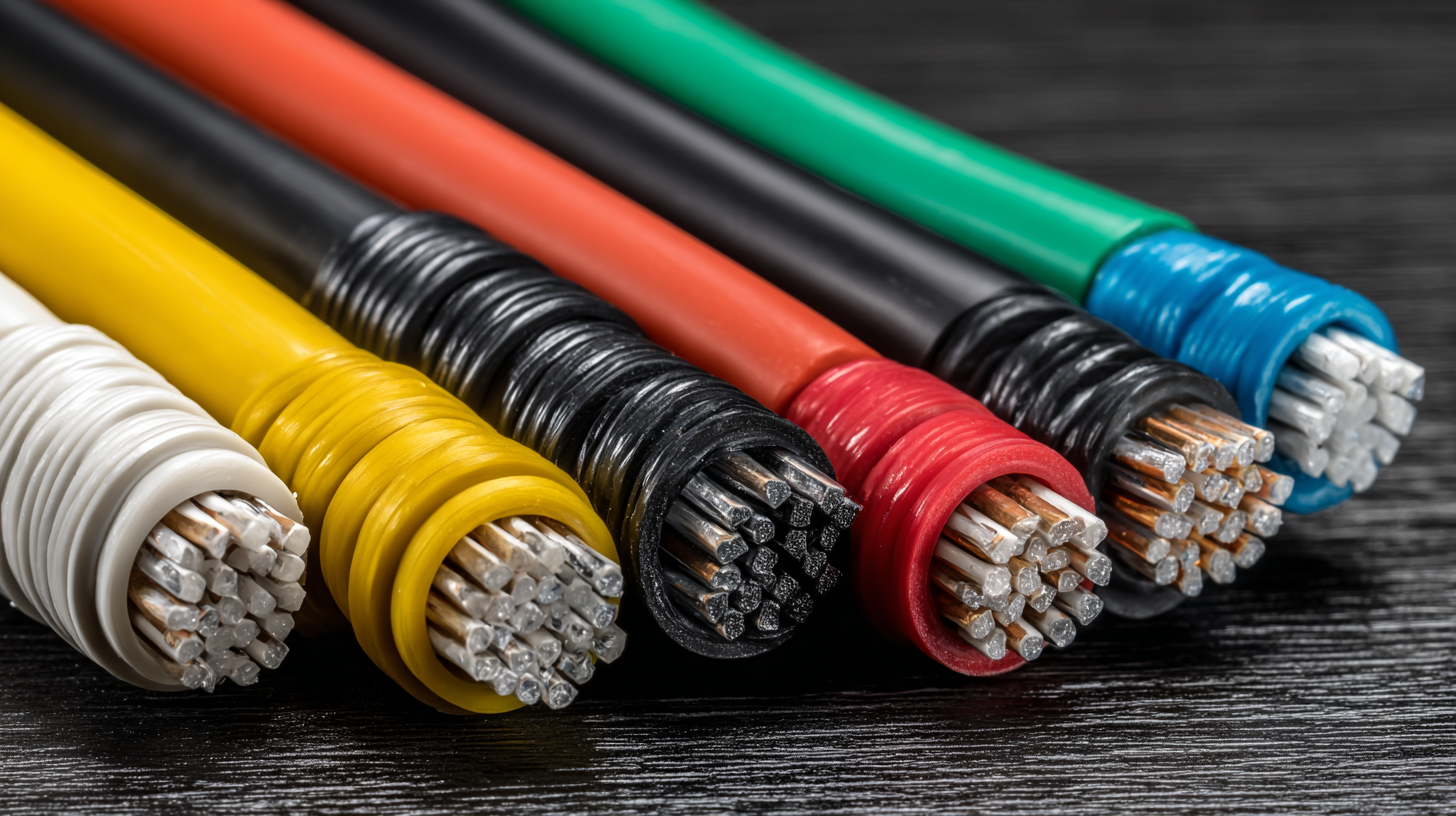

Soow cable presents significant safety advantages over traditional wiring methods, particularly in hazardous environments. Its construction includes a robust outer jacket that encompasses multiple conductors, providing superior insulation and protection against moisture, chemicals, and abrasion. This durability is crucial for reducing risks associated with electrical shorts or fires, especially in industrial settings where explosive environments are a concern.

The increased safety features of Soow cable align well with recent advancements in electrical equipment, such as explosion-proof extension cords designed for specific risk zones. These extension cords allow for multiple devices to be safely connected from a single power source, effectively minimizing hazards in Class 1 Division 1/2 and Class 2 Division 1 areas. The combination of Soow cable with such specialized equipment ensures compliance with safety standards, making it an ideal choice for operators who prioritize risk management in their wiring solutions.

Cost-Effectiveness: Long-Term Savings with Soow Cable

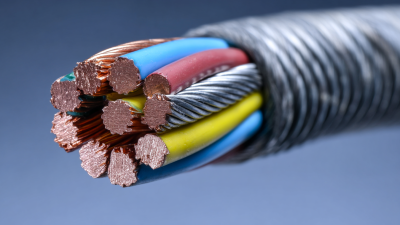

When considering electrical wiring options, cost-effectiveness is a crucial factor, and Soow cable stands out as a prudent choice. Made with durable materials suitable for harsh environments, Soow cable minimizes the need for frequent replacements. Its robust design not only extends the lifespan of the electrical system but also reduces maintenance costs over time. By opting for Soow cable, users can experience fewer disruptions and lower operational expenses due to its reliability.

Moreover, the initial investment in Soow cable pays off through energy efficiency. This type of cable is designed to handle higher currents without overheating, which can lead to reduced energy losses during transmission. In commercial and industrial settings, where large amounts of electricity are necessary, this aspect is particularly beneficial. The long-term savings on energy bills further enhance the cost-effectiveness of using Soow cable, making it an intelligent investment for anyone looking to optimize their electrical wiring solutions.

Versatile Applications: How Soow Cable Fits Various Electrical Needs

Soow cable, known for its durability and flexibility, has become a popular choice for a wide range of electrical applications. Its versatile design accommodates environments that require high performance and resilience, making it suitable for both indoor and outdoor wiring needs. According to a report by the National Electrical Manufacturers Association (NEMA), the use of flexible cables like Soow has increased by over 25% in industrial settings, reflecting the growing demand for adaptable electrical solutions.

In addition to being weather-resistant and oil-resistant, Soow cable is highly efficient in applications such as construction sites, manufacturing facilities, and marine environments. Its ability to withstand extreme temperatures (from -40°F to 140°F) allows it to excel in various operational conditions. A recent study indicates that cables designed for harsh conditions, such as Soow, can reduce downtime in operational environments by up to 30%, highlighting their importance in maintaining productivity and safety in diverse settings.

Related Posts

-

Understanding the Essential Role of Wire and Cable in Modern Technology Systems

-

What is Armoured Cable? Understanding Its Types, Benefits, and Applications

-

The Ultimate Guide to Understanding Different Wire Connector Types for Your Projects

-

Essential Automotive Cable Maintenance Tips for a Smooth Ride

-

Understanding Multi Conductor Cables: Essential Tips for Effective Electrical Wiring

-

2025 Top 5 Industrial Electric Wire and Cable Solutions for Every Business Need