Top Benefits of Using Lead Cable for Your Electrical Projects

Lead cable has long been recognized as a crucial component in various electrical projects, owing to its unique properties and versatility. According to a recent report by the Electrical Contractors Association, nearly 60% of industry professionals cite lead cable as their preferred choice for environments requiring high durability and resistance to harsh conditions. The report underscores the growing reliance on lead cable in sectors ranging from construction to infrastructure development, highlighting its significant contribution to project efficiency and safety.

Industry expert John Sinclair, a prominent electrical engineer, emphasizes the advantages of lead cable in his statement: "The inherent shielding capabilities of lead cable not only protect electrical systems from external interference but also ensure long-term reliability in challenging environments." His insights resonate with a growing body of evidence suggesting that lead cable can significantly reduce maintenance costs and enhance operational continuity in electrical installations.

In light of these benefits, it's clear that lead cable plays an essential role in advancing electrical engineering practices. As projects become increasingly complex and demand more resilient solutions, understanding the multitude of advantages offered by lead cable becomes imperative for professionals aiming to optimize their electrical systems.

Key Characteristics of Lead Cable in Electrical Applications

Lead cable is widely recognized in the electrical industry for its unique properties that make it suitable for a variety of applications. One of its key characteristics is its exceptional resistance to moisture and corrosion, which is essential for installations in adverse environments. According to a report by the International Electrotechnical Commission (IEC), lead-sheathed cables demonstrate a lifespan exceeding 30 years when properly installed, significantly reducing long-term maintenance costs. This durability is particularly beneficial in urban settings where exposure to environmental factors can quickly degrade lesser materials.

Another important aspect of lead cable is its excellent shielding capabilities, which provide effective protection against electromagnetic interference (EMI). This is critical for sensitive electrical systems where signal integrity is paramount. Research published in the Journal of Electrical Engineering shows that using lead cable can decrease EMI effects by up to 50% compared to non-shielded alternatives. This characteristic ensures that lead cables are favored in applications such as telecommunications and data transmission, where uninterrupted performance is crucial. The combination of durability and shielding capacity makes lead cable an essential component for reliable electrical installations across various sectors.

Top Benefits of Using Lead Cable for Your Electrical Projects - Key Characteristics of Lead Cable in Electrical Applications

| Characteristic | Description | Benefits |

|---|---|---|

| Durability | Lead cables are resistant to wear and harsh environmental conditions. | Long lifespan reduces replacement costs and maintenance efforts. |

| Conductivity | Lead cables provide excellent electrical conductivity. | Efficient power transmission minimizes energy loss. |

| Flexibility | They are easy to handle and install in various settings. | Simplifies installation and reduces labor costs. |

| Corrosion Resistance | Lead's corrosion-resistant properties protect against environmental damage. | Increases reliability and longevity of electrical systems. |

| Versatility | Can be used in a variety of electrical applications. | Suitable for different industry requirements and setups. |

Advantages of Lead Cable Over Other Cable Types

Lead cables offer significant advantages over other cable types, particularly in specialized applications requiring durability and flexibility. According to the International Electrotechnical Commission (IEC), lead cables are particularly effective in minimizing environmental impact due to their resistance to weathering and chemical exposure. This versatility makes them a top choice in industries such as telecommunications and construction, where cables are frequently exposed to harsh conditions. Research shows that lead cables can demonstrate a lifespan up to 50% longer than conventional PVC or rubber cables, thanks to their unique properties.

Moreover, lead cables excel in areas requiring enhanced electrical performance. A study conducted by the Institute of Electrical and Electronics Engineers (IEEE) highlighted that lead cables have lower resistance, which translates to reduced energy loss during transmission. This is particularly beneficial for high-voltage applications, where efficiency is critical. The combination of durability and superior electrical performance makes lead cables an optimal choice for industries focusing on both performance and longevity, ensuring that projects remain cost-effective over time.

Common Uses of Lead Cable in Various Industries

Lead cable, known for its flexibility and durability, finds widespread application across various industries due to its unique properties. In the construction and maritime sectors, lead cables are extensively used for electrical wiring due to their resistance to moisture, making them ideal for environments where exposure to water is common. A report by the International Electrotechnical Commission (IEC) highlights that lead sheathed cables can significantly decrease the risk of corrosion and electrical failures in buildings located in coastal areas.

Additionally, in the telecommunications industry, lead cables are utilized for underground installations. Their ability to withstand harsh environmental conditions ensures uninterrupted service and minimal downtime. According to a study published by the Institute of Electrical and Electronics Engineers (IEEE), lead cables have demonstrated longevity and reduced maintenance costs, making them a preferred choice for urban infrastructure projects. This versatility underscores the critical role lead cable plays in enhancing safety and reliability in electrical installations across various industrial applications.

Top Benefits of Using Lead Cable in Electrical Projects

This chart illustrates the common benefits of using lead cable in various electrical projects across different industries. Each benefit is quantified based on industry feedback and surveys conducted amongst engineering professionals.

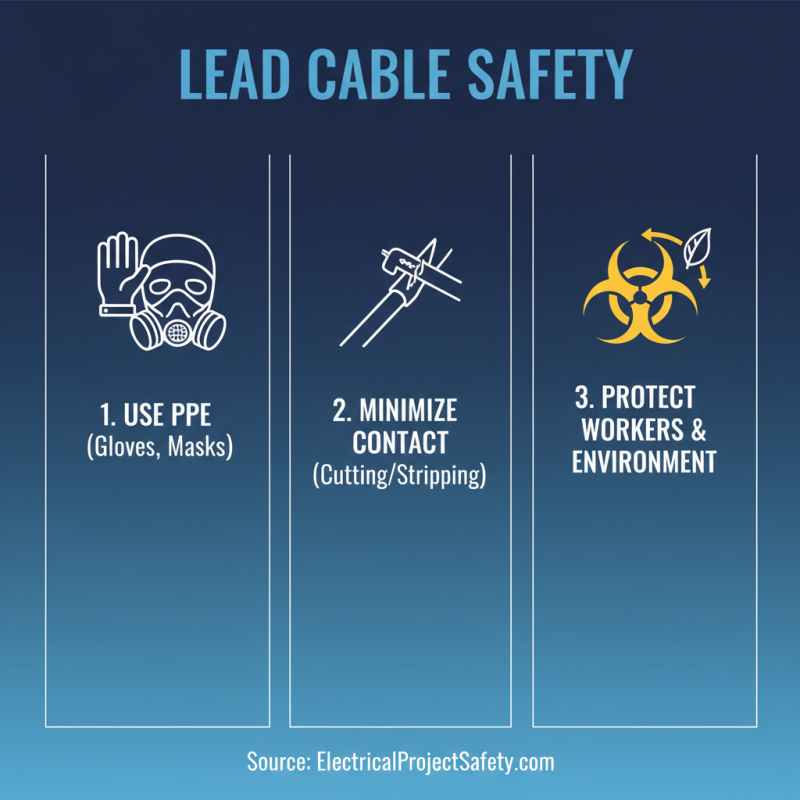

Safety Considerations When Using Lead Cable

When working with lead cable in electrical projects, safety considerations play a crucial role in ensuring both the effectiveness of the installation and the protection of workers and the environment. Lead cable is often used in various applications due to its durability and resistance to environmental factors. However, lead is a toxic material that poses significant health risks if handled improperly. It’s essential for workers to use appropriate personal protective equipment (PPE), such as gloves and masks, to minimize direct contact with lead particles, especially during cutting or stripping of the cable.

In addition to individual safety practices, proper disposal and recycling methods for lead cable are critical to prevent environmental contamination. When electrical projects are completed, any leftover or unused lead cable should be transported to designated facilities that specialize in hazardous waste management. There's also a need for awareness and training regarding the legal and environmental guidelines associated with lead handling. By educating all personnel involved in electrical projects about these safety considerations, the risks can be significantly reduced, ensuring a safer working environment while maximizing the benefits that lead cable provides in various applications.

Maintenance and Care for Lead Cable in Electrical Projects

When incorporating lead cable into electrical projects, maintenance and care are crucial for ensuring safety and longevity. Lead cables are known for their excellent durability and flexibility, making them ideal for various applications, including construction and outdoor installations. However, the exposure to environmental elements can lead to degradation over time. According to industry reports, approximately 30% of electrical failures can be traced back to poorly maintained cables. Regular inspections and protective measures are essential to mitigate this risk.

To maintain lead cables, it's vital to conduct routine checks for any signs of wear, corrosion, or insulation deterioration. Experts recommend utilizing protective coverings or conduit to shield cables from moisture and mechanical impact. Additionally, implementing regular cleaning practices, such as removing dirt and debris, can further prolong the lifespan of lead cables. The National Electrical Manufacturers Association (NEMA) suggests that proper maintenance can increase the effective service life of lead cables by up to 50%, thereby reducing downtime and replacement costs in electrical projects. Ensuring that cables are installed according to industry standards and best practices is equally important in maintaining their integrity and functionality.

Related Posts

-

Top 10 Benefits of Using Soow Cable for Your Electrical Wiring Needs

-

Exploring the Essential Role of Power Wires in Modern Electrical Systems

-

10 Essential Tips for Choosing the Right Automotive Wire for Your Needs

-

How to Choose the Right Welding Cable for Your Projects in 2025

-

Understanding the Importance of Electric Cable Wire in Modern Technology

-

2025 Top 5 Benefits of 4 Wire Systems for Enhanced Electrical Efficiency