Best Ball Screws for Sale Which One Should You Choose?

In the world of precision machinery, selecting the right components is crucial. Among these, ball screws are essential for ensuring accurate linear motion. A ball screw for sale can come from various manufacturers with different specifications. Industry reports indicate that the ball screw market is expected to grow significantly, projected to reach $1.7 billion by 2026. This growth highlights the increasing demand for efficient motion control systems across various industries.

When searching for a ball screw for sale, factors such as load capacity, screw diameter, and lead screw pitch are important. Each of these aspects impacts the performance and longevity of the screw. However, not all manufacturers provide the same quality. Some may cut corners, compromising performance. It’s vital to research and compare options carefully.

Potential buyers often overlook the importance of customer reviews and industry certifications. Not doing so can lead to regret later. Furthermore, understanding the application requirements is key. An ill-suited ball screw can result in inefficiencies or even failures. In choosing the right ball screw, every detail matters. The right decision can drive productivity and enhance overall machinery performance.

Understanding the Functionality of Ball Screws in Machinery

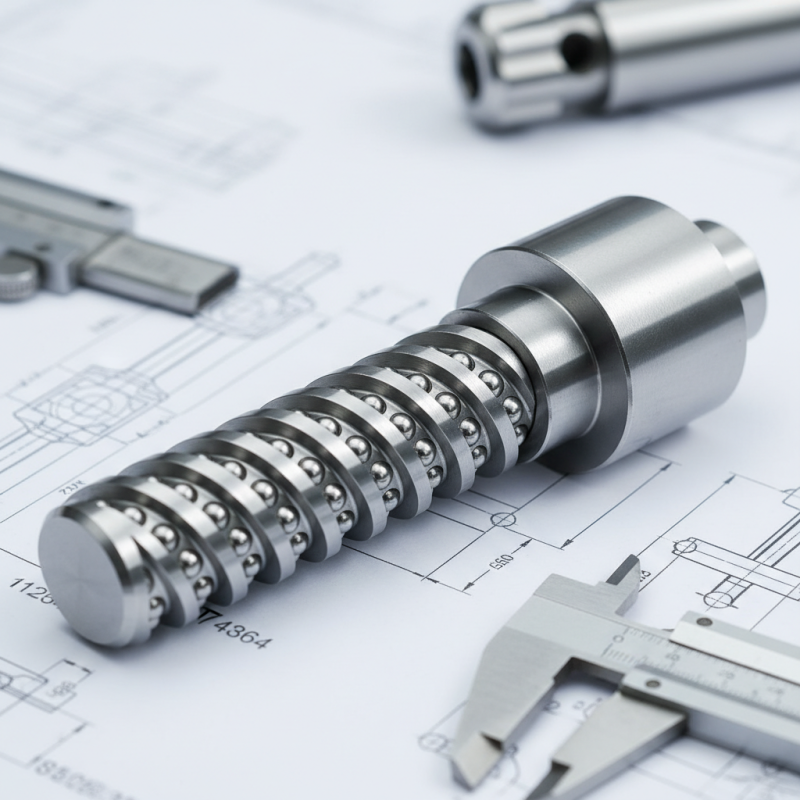

Ball screws are essential components in various machinery, facilitating smooth linear motion. They convert rotational motion into linear movement with high efficiency. According to industry reports, ball screws can achieve up to 90% efficiency, significantly reducing energy consumption in automated systems. This efficiency makes them a preferred choice for CNC machines and robotics. Understanding their mechanism helps in selecting the right one for your needs.

When assessing ball screws, consider the load capacity and precision. They come in differing sizes and configurations to meet specific application requirements. For example, larger ball screws bear heavier loads but may respond slower. It’s crucial to analyze your machine's demands before making a purchase.

Tips: Always review the specifications to match them with your machine's needs. Also, monitor wear and tear for early identification of issues. Regular maintenance can enhance performance and lifespan. Keep in mind that oversizing a ball screw may lead to wasted resources. Make choices that align with your tasks and constraints.

Types of Ball Screws and Their Unique Advantages

When selecting ball screws, understanding their types is crucial. Precision ball screws are renowned for their high accuracy and efficiency. According to industry reports, these screws can achieve an accuracy level of up to ±0.01 mm. This makes them ideal for tasks needing tight tolerances, such as CNC machining.

Another popular type is the rolled ball screw. It offers a more cost-effective solution while maintaining decent performance. While their accuracy may not match that of precision screws, they can achieve tolerances around ±0.1 mm. This makes them suitable for general applications where extreme precision is not critical. However, users should note that investment in higher quality screws can lead to longer service life.

Lastly, there are mini ball screws, perfect for compact spaces. They provide great performance in small packages but can be limited in load capacity. Their smaller size sometimes leads to a compromise on life expectancy. Users should think carefully about the application before choosing. Each type has unique advantages and potential pitfalls, making it essential to analyze needs carefully.

Best Ball Screws: Types and Their Unique Advantages

This bar chart illustrates the unique advantages of different types of ball screws, rated on a scale from 0 to 100. Precision ball screws lead in advantages, followed by customized offerings, showcasing their suitability for various applications.

Factors to Consider When Choosing a Ball Screw

When selecting a ball screw, several critical factors come into play. The load capacity is paramount. Depending on the application, screws must bear varying weights. For instance, heavy machinery requires screws with a higher load rating. According to industry reports, the load capacity can range significantly, with some screws rated for over 100,000 N. It's crucial to assess your specific requirements to avoid issues later.

Another vital aspect is the lead and pitch of the screw. These determine the travel distance per rotation. A smaller lead offers higher precision, while a larger lead increases speed. Finding the right balance is essential for optimal performance. Reports show that choosing the appropriate lead can enhance efficiency by up to 30%. This is particularly important for automated systems.

The material of the ball screw also impacts durability and performance. Steel is common, but various alloys can enhance resistance to wear and corrosion. It's not uncommon for applications to overlook maintenance needs. This can shorten the lifespan of the screw. In many cases, users don't realize that regular inspection can prevent costly replacements. Understanding all these factors will guide you in making an informed decision.

Top Brands and Manufacturers of Ball Screws

When selecting ball screws, understanding the best brands and manufacturers is crucial. Well-made ball screws enhance performance in various applications. Many top brands prioritize precision and durability in design. By examining the manufacturing process, users can assess a brand's reliability.

Each manufacturer has unique features. Some focus on high-speed applications, while others excel in load capacity. For instance, if you need a precise movement, choose a brand with excellent accuracy ratings. On the other hand, for heavy loads, look for robust designs.

Tips: Check reviews and user feedback before buying. It helps identify potential issues. Comparing specifications is also vital. Don't rush; take your time to find the best fit. Reflect on where and how you'll use the ball screws. This thought process can lead to better choices.

Best Ball Screws for Sale Which One Should You Choose?

| Type | Diameter (mm) | Lead (mm) | Load Capacity (N) | Accuracy Class | Material |

|---|---|---|---|---|---|

| Standard Ball Screw | 16 | 5 | 5000 | C5 | Carbon Steel |

| Miniature Ball Screw | 10 | 2 | 2000 | C7 | Stainless Steel |

| High Torque Ball Screw | 20 | 10 | 10000 | C3 | Alloy Steel |

| Precision Ball Screw | 25 | 5 | 8000 | C1 | Carbon Steel |

| Lead Screw | 30 | 12 | 6000 | C6 | Bronze |

Maintenance Tips for Longevity of Ball Screws

Maintaining ball screws is crucial for their longevity. Regular inspections can prevent major breakdowns. Check for signs of wear, such as unusual noises or vibrations. These can indicate that something is amiss. Clean the screws regularly to remove dust and debris that could hinder performance.

Lubrication is key. Use the appropriate grease or oil as specified in the guidelines. Too much or too little can lead to premature failure. Keep an eye on the environment too; humidity or extreme temperatures can affect functionality. Remember, neglecting maintenance may lead to costly repairs later.

Occasionally, you might overlook a detail during upkeep. That’s normal. Reflect on past maintenance tasks and adjust your routine accordingly. Ensure your workspace is clean and organized to facilitate better maintenance practices. A proactive approach can greatly enhance the lifespan of your ball screws.