How to Choose the Best Laser Cutting Machine for Your Needs?

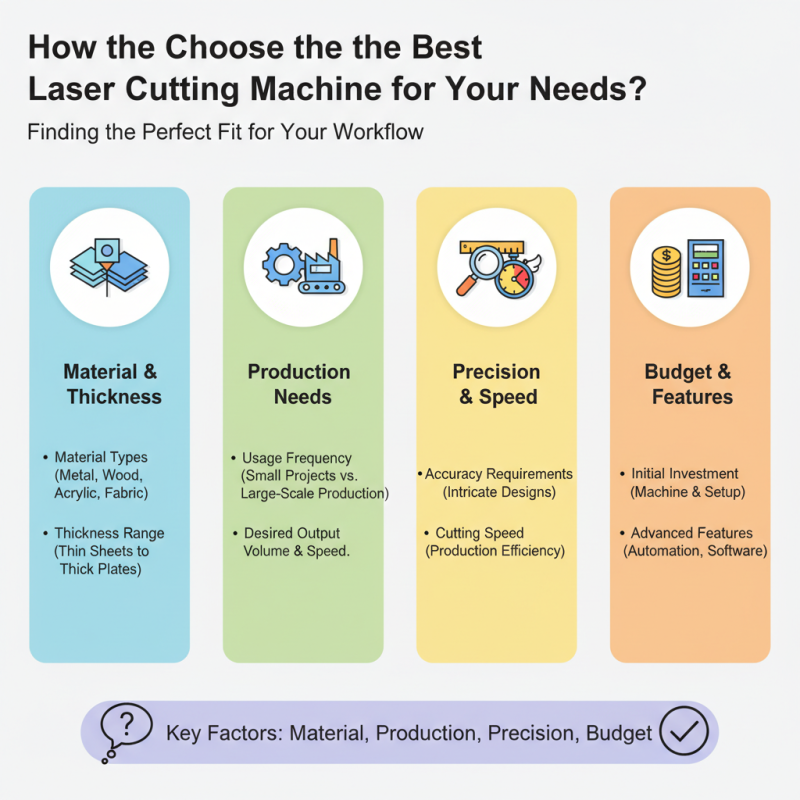

Choosing the right laser cutting machine can be challenging. Many factors come into play. You need to consider your specific needs. This includes the material types and thicknesses you plan to cut.

A laser cutting machine must fit your production goals. Think about how often you will use it. Will it be for small projects or large-scale production? The answer impacts your investment. You also need to consider the machine's precision and speed.

Budget is another key factor. High-end machines offer advanced features, but they come at a price. Sometimes, a less expensive model meets your needs perfectly. Researching these aspects ensures you make an informed choice. Reflect on your requirements and limitations before purchasing. This decision will affect your workflow significantly.

Understanding Your Material Requirements for Laser Cutting

When choosing a laser cutting machine, understanding your material requirements is crucial. Different materials react differently to laser cutting. For instance, wood burns easily, while metal requires higher power. Knowing these details helps you select the right machine.

Consider the thickness of your material. Thicker materials need more powerful lasers. A machine that can handle a variety of thicknesses is versatile. Avoid machines that only serve specific materials. Flexibility is key for creative projects.

Tips: Test with scrap material before cutting the final piece. This saves time and resources. Keep the machine’s software updated for optimal performance. Lastly, regular maintenance checks prevent unexpected issues during operation.

Evaluating the Different Types of Laser Cutting Machines

When selecting a laser cutting machine, understanding the types available is crucial. There are mainly three types: CO2, fiber, and crystal. Each type serves different materials and applications. CO2 machines excel in cutting non-metal materials like wood and acrylic. In contrast, fiber lasers are effective for metals, offering precision and speed.

For instance, industry data highlights that fiber laser cutting machines can achieve speeds of 20 m/min or more. This is significant for companies aiming to boost operational efficiency. However, CO2 machines are often less costly, making them a go-to for budget-conscious users. Understanding these differences will guide you in choosing a suitable machine.

Tips: Consider your primary materials. If cutting metal is your main task, a fiber laser might be the best fit. Evaluate your production volume too. High-speed machines are ideal for large-scale operations, but they may not be necessary for smaller projects. Reflect on future needs as well; investing in a versatile machine can save costs long-term. Choosing the right machine is about balancing capabilities with your specific requirements.

How to Choose the Best Laser Cutting Machine for Your Needs?

| Machine Type | Power Source | Cutting Thickness (mm) | Speed (mm/min) | Suitable Materials |

|---|---|---|---|---|

| CO2 Laser Cutter | CO2 | 5-20 | 3000-10000 | Acrylic, Wood, Fabric |

| Fiber Laser Cutter | Fiber | 1-10 | 5000-20000 | Metal, Stainless Steel, Brass |

| Nd:YAG Laser Cutter | Nd:YAG | 1-5 | 1000-5000 | Metal, Ceramics |

| UV Laser Cutter | UV | 0.5-5 | 2000-3000 | Plastic, Glass, Wood |

Assessing the Power and Speed Specifications

When selecting a laser cutting machine, examining power and speed is crucial. Generally, laser machines operate between 40W to 400W. A higher wattage means the ability to cut thicker materials. For example, a 60W laser can effectively cut through acrylic up to 1/4 inch thick, while a 100W laser can handle thicker metals, reaching up to 0.5 inch.

Speed is equally important. Speeds range from 1 to 100 inches per minute. The right speed depends on the material type and thickness. For instance, cutting steel often requires slower speeds for precision. A speed of 20 inches per minute works well for metals, while the same can go up to 80 inches per minute for softer materials like wood.

Tip: Always balance speed and power. High speed with low power may result in poor cuts. Conduct tests to ensure optimal settings. Also, keep in mind that different materials respond uniquely to power settings. What works for one may not suit another perfectly.

Reflect on your specific cutting needs. Do you prioritize speed or thickness? Knowing this will help narrow down your options effectively. Remember, sometimes too much power can lead to burn marks. Adjusting your approach based on real-time results is essential. A well-researched power and speed combination results in quality outputs.

Comparing Cost and Budget Considerations

When considering a laser cutting machine, budget is crucial. A report by MarketsandMarkets indicates that the global laser cutting machine market is expected to reach $4.5 billion by 2023. This growth highlights the increasing demand for precision cutting across various industries, including manufacturing, automotive, and aerospace.

Understanding the cost factors is essential. Basic machines can start as low as $5,000, while high-end systems may exceed $100,000. It’s vital to evaluate your production needs. Investing too little may hinder productivity. On the other hand, overspending can strain finances.

Maintenance costs also play a role. Reports suggest that maintenance can account for up to 10% of the initial investment annually. This aspect is often overlooked. Not planning for ongoing expenses could lead to unexpected financial strain. Additionally, consider training costs for staff. Well-trained operators can significantly improve efficiency. Balancing all these factors is challenging yet essential.

Looking into Maintenance and Support Services Available

When selecting a laser cutting machine, maintenance and support services are crucial. According to a recent industry report, 30% of businesses face downtime due to inadequate support. Ensuring that the manufacturer offers comprehensive maintenance plans can save time and money in the long run. Look for providers that understand your specific operational needs.

Tips: Regular maintenance checks can extend your machine's lifespan. Schedule them at least once a month. Additionally, having quick access to technical support can significantly reduce operational disruptions. Some companies offer 24/7 support, which is essential in a fast-paced production environment.

It's important to note that not all support services are created equal. Some may lack the expertise needed for advanced issues. Research customer reviews and testimonials to gauge the reliability of their service. If possible, visit facilities that use the same machines to see their support in action. This hands-on assessment can yield insights into their effectiveness and responsiveness.