How to Choose the Right Thermocouple Wire for Your Temperature Measurement Needs

In the realm of temperature measurement, selecting the appropriate thermocouple wire is critical for ensuring accurate readings and reliable performance. Renowned thermocouple specialist Dr. Emily Carter emphasizes the significance of this choice: "The right thermocouple wire not only enhances measurement precision but also extends the lifespan of your temperature sensing devices." This statement highlights the importance of understanding the various types and specifications of thermocouple wires available on the market.

Thermocouple wires are pivotal in a wide range of applications, from industrial processes to laboratory experiments. Each type of thermocouple wire possesses distinct characteristics that can influence its suitability for different temperature ranges and environments. Recognizing these differences is essential for engineers and technicians tasked with developing effective temperature monitoring systems. By comprehensively evaluating the material composition, insulation, and temperature ratings of thermocouple wires, users can optimize their systems for accuracy and durability.

As we delve into the intricacies of thermocouple wire selection, it will become evident that informed decisions lead to better operational outcomes. Understanding the specific requirements of your application lays a solid foundation for achieving optimal temperature measurement results. This guide aims to equip you with the necessary knowledge to navigate the complexities of thermocouple wire selection, ensuring that you meet your temperature measurement needs with confidence.

Understanding Thermocouples and Their Applications

Thermocouples are widely used temperature sensors that convert thermal energy into electrical voltage through the thermoelectric effect. They consist of two dissimilar metal wires joined at one end, known as the junction. As the junction experiences temperature changes, it generates a voltage proportional to the temperature difference between the junction and the reference point. This property makes thermocouples indispensable in various industries, including manufacturing, aerospace, and automotive, where precise temperature measurement is critical.

In practice, thermocouples can be categorized into several types based on the metals used and their temperature tolerance. Common types include Type K, Type J, and Type T, each offering distinct advantages suitable for different applications, from extreme high temperatures to cryogenic environments. Their versatility allows for usage in everything from industrial equipment monitoring to laboratory experiments. Understanding the specific requirements of your application, including the temperature range, environment, and required response time, is essential to select the right thermocouple wire, which directly affects the accuracy and reliability of temperature measurements.

Key Factors to Consider When Selecting Thermocouple Wire

When selecting thermocouple wire for your temperature measurement needs, several key factors should guide your decision. First, consider the type of thermocouple you will be using, as different thermocouple types (such as Type K, J, T, etc.) require specific wire compositions. Each type has its own temperature range and properties, making it essential to match the wire to your application for accurate readings.

Another important factor is the environmental conditions where the thermocouple will be installed. Factors such as exposure to moisture, chemicals, or high temperatures can affect the wire’s performance and lifespan. Selecting a wire with appropriate insulation and protection can mitigate these risks. For instance, look for wires with high-temperature insulation if you plan to operate in extreme conditions.

**Tips:** Always verify the temperature rating of the wire to ensure it aligns with your application's needs. Additionally, if your measurement area is prone to interference, consider using shielded thermocouple wire to enhance accuracy. Lastly, ensure compatibility with any connectors or accessories you plan to use, as this can significantly influence both installation and measurement reliability.

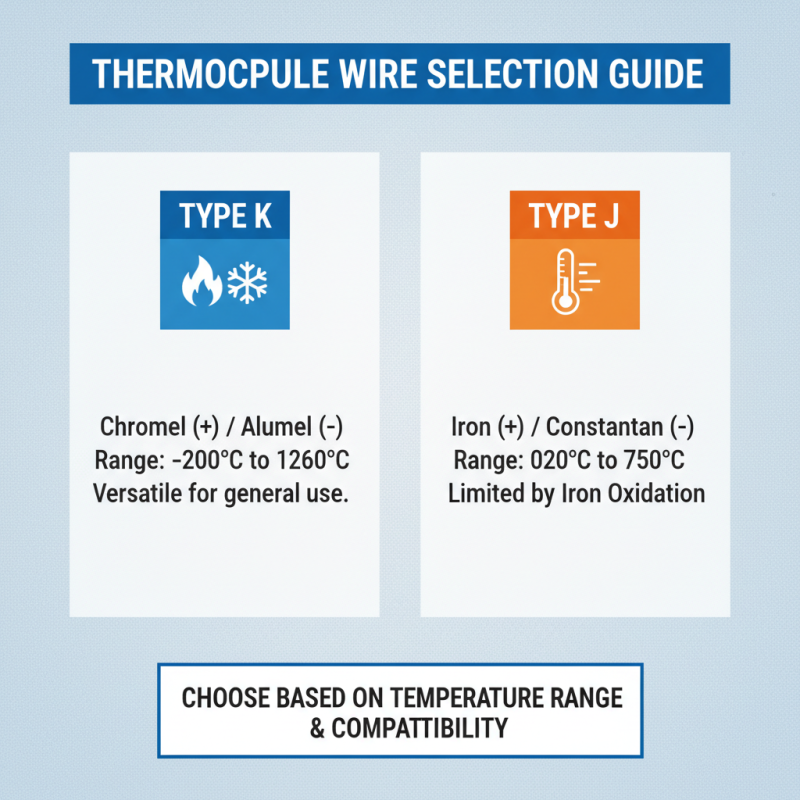

Types of Thermocouple Wires and Their Characteristics

When selecting thermocouple wires, it is essential to understand the various types available and their specific characteristics. The most commonly used types include Type K, Type J, Type T, and Type E thermocouples, each suitable for different temperature ranges and environments. Type K, which consists of Chromel and Alumel, is widely favored for its broad temperature range from -200°C to 1260°C, making it ideal for various industrial applications. Type J, made from iron and constantan, is often used for lower temperature ranges, typically between -40°C and 750°C but has the disadvantage of oxidizing at high temperatures.

Type T thermocouples, utilizing copper and constantan, are particularly suitable for low-temperature measurements, ranging from -200°C to 350°C, and are known for their stability and resistance to corrosion. On the other hand, Type E thermocouples, featuring nickel-chromium and constantan, are known for their high sensitivity and can operate effectively from -200°C to 900°C. Understanding these types and their distinct characteristics helps in choosing the right thermocouple wire that meets specific temperature measurement requirements and environmental conditions.

Temperature Ranges and Compatibility with Thermocouples

Choosing the right thermocouple wire for your temperature measurement needs involves understanding the specific temperature ranges and compatibility of different thermocouple types. Thermocouples are categorized into various types based on their metal composition and operating temperature ranges. For example, Type K thermocouples, made from Chromel and Alumel, can operate effectively in the temperature range of -200°C to 1260°C, making them suitable for a wide array of applications. In contrast, Type J thermocouples, composed of Iron and Constantan, are limited to a maximum temperature of around 750°C due to the oxidation of Iron at elevated temperatures.

When selecting thermocouple wires, it is also essential to consider their compatibility with the environment in which they will be used. For instance, in a vacuum or inert gas atmosphere, certain materials may not perform optimally. According to a report published by the National Institute of Standards and Technology (NIST), proper material selection can improve measurement accuracy by up to 15% in critical applications. Therefore, a detailed understanding of your specific environment and required temperature range is vital for ensuring accurate and reliable temperature readings.

Tips: Always refer to the temperature calibration data provided by credible sources when selecting thermocouple wires, as they will help you make informed decisions regarding your application's requirements. Additionally, consider the thermal conductivity and insulation ratings of the thermocouple wires, as these factors play a significant role in maintaining the precision of your temperature measurements over time.

Maintenance and Safety Tips for Thermocouple Installation

When installing thermocouples, proper maintenance and safety practices are crucial to ensure accurate temperature measurements and prolong the lifespan of the sensors. One essential maintenance tip is to regularly inspect the thermocouple wiring for any signs of wear or damage. Over time, exposure to extreme temperatures, chemicals, or mechanical stress can compromise the integrity of the wire, leading to faulty readings. It’s advisable to schedule periodic assessments to identify any issues before they affect the performance of the thermocouple.

Safety is another critical aspect of thermocouple installation. When working with thermocouples, always follow standard electrical safety protocols. This includes ensuring that the power supply is turned off during installation or maintenance to prevent electric shock. Additionally, use appropriate personal protective equipment (PPE) such as gloves and safety glasses to protect against accidental injuries. It's also important to correctly secure the thermocouple to avoid mechanical issues that could arise from vibrations or movements in the environment, thus maintaining not only safety but also measurement accuracy over time.

Related Posts

-

Top 10 Uses of Thermocouple Wire in Industrial Applications

-

2025 Top 5 Industrial Electric Wire and Cable Solutions for Every Business Need

-

Understanding Lead Cables: Essential Insights for Safe Electrical Installations

-

How to Choose the Right Welding Cable for Your Projects in 2025

-

Top Types of Cable Wire You Need to Know for Effective Wiring Solutions

-

Essential Automotive Cable Maintenance Tips for a Smooth Ride