How to Choose the Right Marine Cable for Your Project?

Choosing the right marine cable for your project is crucial. The marine industry is complex and requires attention to detail. According to a report by MarketsandMarkets, the global marine cable market is projected to reach $15.4 billion by 2026. This growth underscores the importance of selecting the right cables.

Marine cables must withstand harsh environments. These cables are subject to saltwater, temperature changes, and UV exposure. A poor choice can lead to failures, which can be costly. For example, the failure rate of marine cables can reach 20% if not properly selected. It is vital to consider these factors in your decision-making process.

Furthermore, not all cables are created equal. Different projects have varying needs. Some may require cables with high tensile strength, while others need specific insulation materials. Reflecting on past projects can provide valuable insights. Your experiences, even the challenging ones, can guide you in making informed decisions about marine cables.

Factors to Consider for Selecting Marine Cable Types and Applications

When selecting marine cables for your project, consider several key factors. One important aspect is the environmental conditions. Marine cables encounter moisture, saltwater, and sometimes extreme temperatures. Choosing a cable that can withstand these conditions is crucial. Think about insulation materials. Some types are better suited for harsh environments.

Another factor to reflect on is cable flexibility. Projects requiring tight bends may benefit from more flexible cables. Rigid cables could lead to installation challenges. Pay attention to cable ratings too. They dictate how much current the cable can handle safely. Underestimating needs can cause future failures.

Lastly, consider the application of the cable. Different uses require specific features. For example, communication cables may require additional shielding. This helps prevent signal interference. Don't overlook installation requirements either. The complexity of your project can affect cable choice. Proper planning and consideration of these factors lead to a more successful outcome.

Understanding Marine Cable Ratings: Voltage, Temperature, and Environment

When selecting marine cables, understanding ratings is crucial. Voltage ratings indicate the maximum electric pressure a cable can handle. Most marine cables fall between 600V to 1kV, suitable for typical marine applications. However, for specialized projects, like those involving high-power equipment, you may need cables rated higher than 1kV.

Temperature ratings reflect the environment where cables will be used. Cables designed for marine environments must endure extreme heat and cold. For example, a cable with a temperature rating of -40 to 90 degrees Celsius is preferable for harsh conditions. This ensures safety and longevity.

**Tip:** Always check the cable's insulation type. Certain insulations withstand saltwater exposure better than others.

Additionally, environmental ratings highlight moisture and chemical resistance. Cables are often exposed to corrosive elements in marine settings. Choosing cables with proper ratings can prevent failures and extend equipment life.

**Tip:** Don’t overlook local regulations, which may dictate specific standards for marine installations. Ignoring these could lead to costly repairs later on.

Choosing the right marine cable means balancing these factors. Each project has unique demands, and assessing these allows for informed decisions. Taking time to reflect on your cable selections can prevent future challenges.

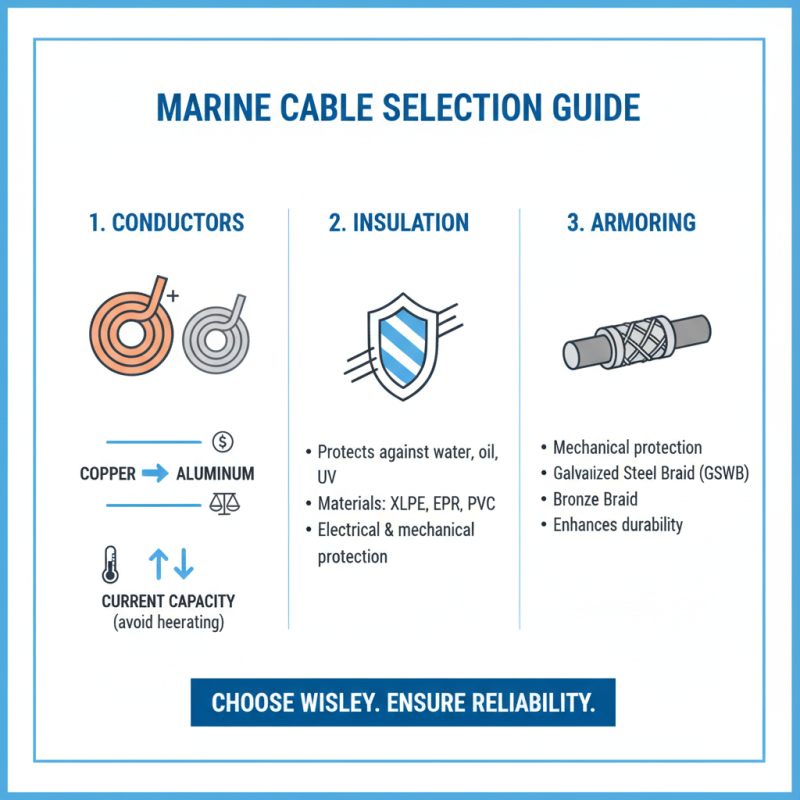

Key Specifications of Marine Cables: Conductors, Insulation, and Armoring

Selecting the right marine cable involves understanding key specifications like conductors, insulation, and armoring. Conductors serve as the core of any cable, usually made from copper or aluminum. Copper offers better conductivity, but aluminum is lighter and cost-effective. It's crucial to consider the current-carrying capacity of the conductor—too small can lead to overheating.

Insulation is vital for protecting the conductor from moisture and electrical hazards. Common materials include PVC and cross-linked polyethylene. PVC is affordable but may not withstand harsh environments. Conversely, cross-linked polyethylene provides better durability and resistance to chemicals. Evaluate the insulation material based on the project’s environmental conditions.

Armoring adds another layer of protection, shielding the cable from mechanical damage. Types of armoring range from steel wire to aluminum tape. Steel wire offers excellent protection against heavy impact but is heavier. In contrast, aluminum tape is lighter but may not be suitable for high-risk areas. Make sure to match the armoring type with the specific demands of your project. Balancing these specifications can be challenging, yet it is essential for ensuring safety and durability in marine applications.

Compliance with Industry Standards: UL, IEC, and ABS for Marine Cables

When selecting marine cables, compliance with industry standards is vital. Major standards include UL, IEC, and ABS. These guidelines ensure safety and performance. According to a 2021 report by the International Marine Certification Institute (IMCI), approximately 68% of marine cable failures relate to non-compliance with these standards.

UL standards focus on safety and material quality. Cables must withstand harsh marine environments. IEC standards, on the other hand, emphasize electrical performance and environmental resilience. They address potential weather-related impacts that cables may face. ABS standards ensure that cables meet marine-specific criteria for durability.

Choosing cables that comply with these standards enhances reliability. Non-compliant cables often lead to costly failures. A recent study revealed that 40% of marine projects experienced delays due to cable-related issues. Ensuring compliance at the outset can save time and resources in the long run. It's an aspect that deserves careful consideration by project managers and engineers alike.

Compliance with Industry Standards for Marine Cables

Cost-Benefit Analysis: Evaluating Lifetime vs. Initial Investment in Marine Cables

Choosing the right marine cable involves more than just comparing prices. A cost-benefit analysis is crucial. Consider the lifetime of the cable. High-quality cables may cost more initially, but they often last longer. This longevity can lead to savings over time. Cheap cables might seem attractive, but frequent replacements add up.

Tips: Always evaluate the environment where the cables will be used. Harsh conditions can impact cable performance. Also, check the warranty. A solid warranty often reflects confidence in the cable's durability.

Think about installation costs too. A more expensive cable might be easier to install, reducing labor costs. Some cables require specialized tools or training, which can increase overall expenses. Always ask yourself: How long do I expect this cable to last? Weighing these factors is essential in making a wise decision.

How to Choose the Right Marine Cable for Your Project? - Cost-Benefit Analysis: Evaluating Lifetime vs. Initial Investment in Marine Cables

| Cable Type | Initial Cost ($/m) | Expected Lifetime (Years) | Maintenance Cost ($/year) | Total Cost Over Lifetime ($) |

|---|---|---|---|---|

| XLPE Insulated Cable | 15 | 25 | 2 | 65 |

| PVC Insulated Cable | 10 | 15 | 3 | 55 |

| EPR Insulated Cable | 20 | 30 | 1 | 61 |

| Rubber Insulated Cable | 25 | 20 | 4 | 104 |

Related Posts

-

2025 Top 10 Marine Cable Innovations Transforming Global Connectivity

-

10 Best Multi Conductor Cables for Superior Electrical Performance in 2023

-

Top 10 Uses of Thermocouple Wire in Industrial Applications

-

Understanding Lead Cables: Essential Insights for Safe Electrical Installations

-

Essential Automotive Cable Maintenance Tips for a Smooth Ride

-

2025 Top 5 Benefits of 4 Wire Systems for Enhanced Electrical Efficiency