How to Choose the Right Welding Cable for Your Project?

Choosing the right welding cable for your project can be challenging. There are many factors to consider. A welding cable is not just a wire; it connects your equipment and supplies power.

The size and type of welding cable greatly impact performance. You must think about the welding process you will use. Different applications require different cables. For instance, MIG welding often needs a flexible cable. In contrast, TIG welding may require a different gauge.

Safety is also crucial. Poorly selected cables can lead to hazards during welding. A proper welding cable ensures you have a reliable connection. This can make all the difference in the success of your project. Before making a choice, reflect on your specific needs and desired outcomes. Think about your experience level as well. It may surprise you how the right cable can enhance your work.

Understanding the Basics of Welding Cables

Welding cables are essential for any welding project. They conduct electricity from the power source to the welding machine. Understanding their construction is important for selection. Most cables consist of copper wires that provide excellent conductivity. According to a report by the International Institute of Welding, the conductivity can reach up to 98% in high-quality copper cables.

The insulation type is also crucial. PVC and rubber are common materials used for insulation. PVC offers flexibility and is cost-effective, while rubber withstands extreme conditions. Industry data suggests that welding cables must handle temperatures between -40 to 90 degrees Celsius. Ignoring this can lead to failure during critical tasks.

Length and gauge of the cable matter significantly. A common error is selecting the wrong gauge, which can impact performance. Larger projects may require thicker cables to minimize voltage drop. Industry standards recommend using a cable gauge that matches the amperage needs of the welder. Improper selection can result in overheating or insufficient performance.

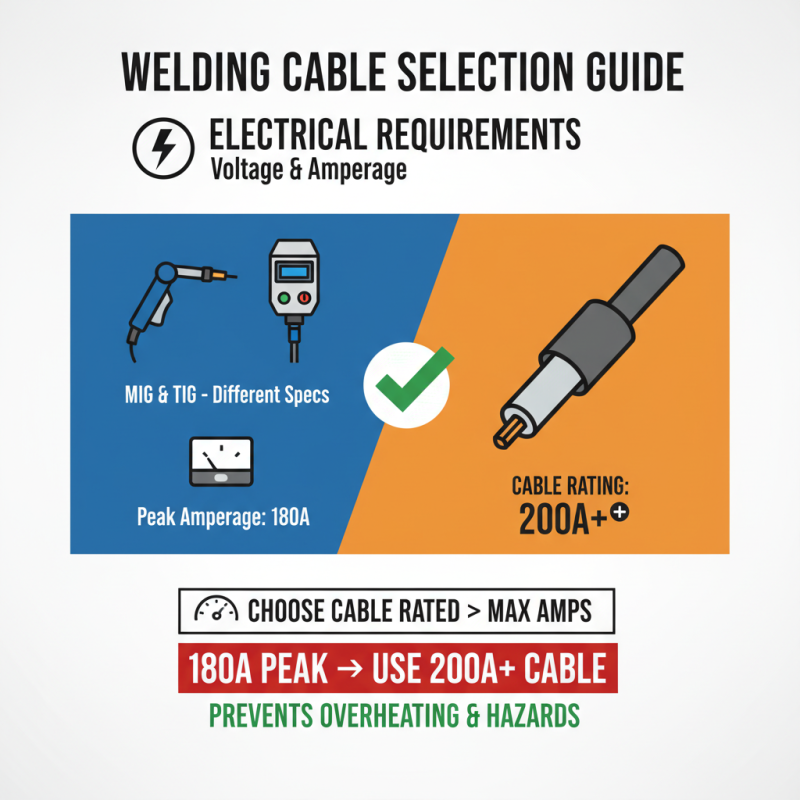

Identifying Your Project's Electrical Requirements

When selecting a welding cable, understanding your project's electrical requirements is crucial. Determine the voltage and amperage involved. For instance, common welding processes like MIG and TIG can require different specifications. According to industry analysis, choose cables rated above the maximum amperage. A cable rated for 200 amps should be used if your setup peaks at 180 amps. This prevents overheating and potential hazards.

Next, consider the cable length. Longer cables increase resistance, which can cause a voltage drop. This is particularly critical for projects requiring high precision. The American Welding Society suggests keeping the cable length to a minimum, ideally under 50 feet for optimal performance. If longer distances are necessary, consider increasing the cable gauge for efficiency.

Lastly, don't overlook insulation types. Different materials offer varying levels of flexibility and durability. PVC and rubber are surfaces often chosen for dynamic movements. Yet, they may not fare well in extreme conditions. Evaluate the environment where you will work. Harsh weather can deteriorate lesser-quality insulation, leading to unexpected failures. Thoroughly assessing these factors can lead to safer and more effective welding outcomes.

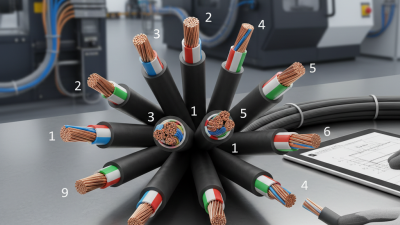

Selecting the Right Gauge and Length for Your Welding Cable

Choosing the right gauge and length for your welding cable is crucial. The cable gauge influences the current-carrying capacity. Generally, a lower gauge means a thicker wire, which can carry more current. According to industry data, a 6-gauge cable is ideal for machines with up to 200 amps, while a 2-gauge cable suits higher demands, reaching 300 amps.

Length also affects performance. Longer cables can lead to voltage drop, impacting your welding quality. If a cable is too long, you may need a thicker gauge to compensate. The American Welding Society (AWS) suggests keeping weld leads shorter than 100 feet to minimize these losses.

Tips: Always calculate your requirements before purchasing. Consider not only current but also the distance between your power source and workpiece.

Another point to ponder: excess cable can cause tangling and accidents. A cluttered workspace may lead to mistakes. Thus, invest time in planning your cable layout. Use cable organizers to keep everything neat and accessible.

Evaluating Cable Insulation and Durability Features

Choosing the right welding cable is crucial for ensuring safety and effectiveness in your projects. One key factor is cable insulation. Insulation materials protect the conductor and prevent electrical shock. Rubber and PVC are common choices. They offer flexibility and resistance to environmental factors. However, cheaper materials can degrade quicker, impacting performance.

Durability is another essential feature. Look for cables designed to withstand wear and tear. Heavy-duty cables can handle abrasive surfaces and harsh conditions. Pay attention to the cable's temperature rating too. Some cables perform poorly in extreme heat or cold. A cable that is too rigid in freezing temperatures may snap or break when handled.

Remember to check the cable's ratings before making a decision. Not all cables are created equal. Sometimes, low-cost options can lead to more problems than solutions. Take time to evaluate your needs and project specifications. A little extra research now can save you headaches later.

How to Choose the Right Welding Cable for Your Project? - Evaluating Cable Insulation and Durability Features

| Cable Type | Insulation Material | Durability Rating | Temperature Range (°C) | Flexibility Rating |

|---|---|---|---|---|

| Type A | PVC | Medium | -10 to 60 | Good |

| Type B | Rubber | High | -20 to 80 | Excellent |

| Type C | EPR | Very High | -30 to 90 | Very Good |

| Type D | Silicone | High | -50 to 150 | Good |

Comparing Different Types of Welding Cables on the Market

Choosing the right welding cable is crucial for project success. There are numerous types of welding cables available. Each type has its strengths and weaknesses. For instance, cables made with rubber insulation are often flexible and durable, making them ideal for heavy-duty tasks. However, they may not be suited for extreme temperatures.

In contrast, PVC insulation cables tend to be more rigid. They are cost-effective and adequate for lighter applications. A study from the National Electrical Manufacturers Association states that cables with better insulation can reduce energy losses by up to 10%. This factor adds to long-term savings, though initial costs may be high.

When selecting a welding cable, consider not just the current rating, but also the environment. Cables intended for outdoor use must resist UV damage. Some inexpensive cables may deteriorate quickly under sunlight, questioning their long-term investment value. Understanding these details can maximize effectiveness while minimizing potential setbacks in your welding projects.

Related Posts

-

2025 Guide to Choosing the Right Wire and Cable for Your Projects

-

Top 10 Benefits of Using Soow Cable for Your Electrical Wiring Needs

-

Top Types of Cable Wire You Need to Know for Effective Wiring Solutions

-

Top 10 Control Cable Types for Optimal Performance in Industrial Applications

-

Exploring the Essential Role of Power Wires in Modern Electrical Systems

-

Top 10 Uses of Thermocouple Wire in Industrial Applications