How to Choose the Best Butterfly Valves for Sale?

Choosing the right butterfly valves for sale can be a daunting task. With numerous options available, it's easy to feel overwhelmed. Understanding your specific needs is crucial. Whether you're working on a small plumbing project or a large industrial application, the right valve makes a difference.

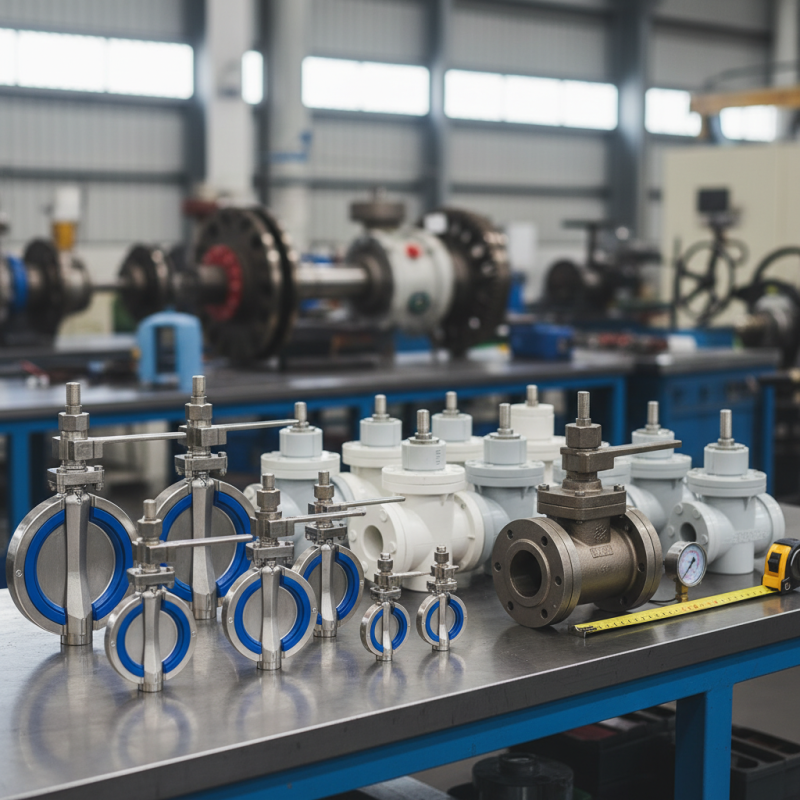

Consider the materials used in butterfly valves for sale. They come in various options, including stainless steel and PVC. Each material offers different benefits and limitations. It's important to assess their performance in your specific environment. For instance, corrosive environments might require a more durable choice.

Additionally, think about the size and pressure ratings. Not all valves fit every system. A valve that works in one setup may not function well in another. Reflect on your project requirements; this will guide you in making an informed decision. The right selection can enhance efficiency and longevity in your system.

Understanding Butterfly Valve Types: A Comprehensive Overview

When selecting the right butterfly valve, understanding the types is crucial. Butterfly valves come in several variations. Common types include the fully lined, resilient seated, and high-performance valves. Each type serves specific applications and environments. For example, a resilient seated valve is great for water applications. However, high-performance valves work better in high-pressure scenarios.

Tips for choosing the right valve: consider the material it’s made from. Factors like temperature and pressure resistance can greatly impact performance. Always inspect the sealing method too. Some seals perform better in extreme conditions.

Another important aspect is size. A valve that’s too large can cause flow issues. One that’s too small may lead to pressure loss. It’s often a challenge to find the perfect balance. Many factors come into play, and it’s perfectly okay to seek advice from an expert. Don't rush the decision; take your time to evaluate options thoroughly.

Key Factors Influencing Butterfly Valve Selection and Performance

When selecting the best butterfly valves, several key factors influence your decision. First, consider the material. Different applications require different materials. For example, stainless steel is ideal for corrosive environments. Plastic valves may be more suitable for water systems. Match the material to your specific needs.

Another factor is the size of the valve. A miscalculation can lead to performance issues. Measure the pipe diameter carefully. This ensures a proper fit and optimal flow. Remember that a larger valve doesn’t always mean better functionality. A small oversight can cause leaks or inefficiencies.

**Tips:** Always check the pressure rating of the valve. High-pressure systems require valves rated for such conditions. Also, pay attention to the valve's sealing performance. A good seal prevents leaks and enhances longevity.

Consider the installation process too. Some valves are easier to install than others. Look for designs that simplify this task. Review feedback from other users about their installation experiences. Remember, easy installation can save you time and money.

Butterfly Valve Performance Factors

Material Considerations: Choosing the Right Butterfly Valve for Your Needs

When selecting butterfly valves, material matters significantly. The right choice affects durability, performance, and resistance to corrosion. Common materials include stainless steel, cast iron, and PVC. Each has unique benefits and limitations. Stainless steel offers excellent strength but is more expensive. Cast iron is robust and affordable but can corrode over time. PVC is lightweight and resistant to chemicals, yet it may not withstand high pressures.

Tips: Consider the operating environment. If chemicals are a concern, opt for materials that resist these substances.

In addition, temperature plays a crucial role. For high-temperature applications, stainless steel is often the better choice. It can handle extreme conditions without compromising performance. However, it's essential to assess the specific requirements of your system.

Lastly, evaluate your budget. While it might be tempting to choose cheaper options, investing in quality materials can save costs in the long run. Poor material selection can lead to maintenance issues and replacements. Remember, the right butterfly valve is an investment in efficiency and safety.

Industry Standards and Certifications for Butterfly Valves Explained

When selecting butterfly valves, understanding industry standards is crucial. Many companies rely on certifications like API, ANSI, and ASME. These certifications ensure that the valves meet specific performance and safety criteria. For instance, the American Petroleum Institute (API) has rigorous testing protocols. Valves must pass tests under high pressure and temperature. Failure in these tests can lead to severe consequences.

Moreover, data shows that compliance with these standards can reduce the risk of valve failure by up to 30%. It's not just about performance; it's about safety. In some studies, improperly certified valves caused significant operational disruptions. Even minor failures can lead to costly repairs and downtime.

Buyers should also consider the manufacturer's adherence to ISO standards. ISO certifications indicate that a company follows established quality management practices. Each butterfly valve should ideally have a traceable history of certifications. Without this, it becomes challenging to assess reliability. Make sure to review the documentation thoroughly. It often reveals insights that may affect your choice.

Sizing Calculations: Ensuring Optimal Flow and Pressure Control

When selecting butterfly valves, sizing is critical. The right size ensures efficient flow and can prevent pressure drops. Calculating the correct size requires understanding the application. Factors like fluid type, temperature, and pressure play a significant role. Oversized valves can lead to turbulence. Undersized valves may restrict flow and damage your system.

Consider the flow rate and the diameter of the pipeline. A simple formula can help determine the required valve size. Yet, many overlook these calculations. This oversight often leads to operational hiccups. Evaluate the entire system design carefully. Even slight adjustments can improve performance.

Test your calculations with real-world scenarios. Consider factors like angle of installation and ambient conditions. Neglecting these details may lead to unexpected results. Remember, an optimal choice today can save time and resources later. Reflect on your needs and ensure you choose wisely.