How to Choose the Right 3 Core Cable for Your Electrical Projects?

When undertaking electrical projects, selecting the right "3 core cable" is crucial. Industry expert John Smith emphasizes, "Choosing the correct cable can prevent future issues." This statement underlines the importance of making informed decisions.

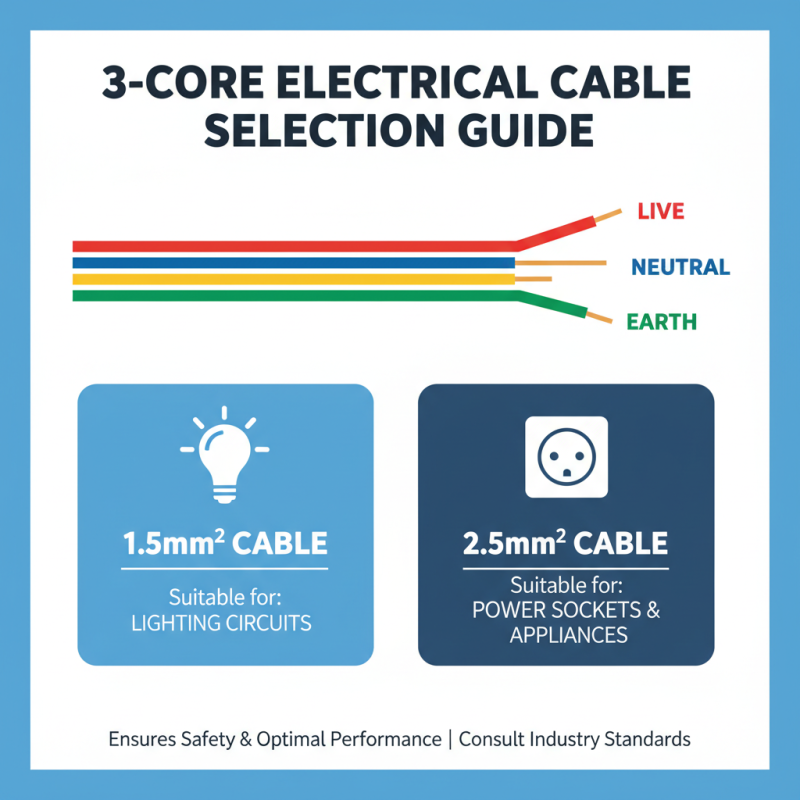

3 core cables offer versatility for various applications. They feature three conductors: live, neutral, and earth. Understanding their specifications is vital for safety and efficiency. Many professionals overlook important details, leading to potential hazards.

For instance, not all 3 core cables are the same. Differences in insulation and current ratings can significantly impact performance. Ignoring these factors could result in failures. It's essential to evaluate options carefully for each project. Remember, a poorly chosen cable could compromise safety and functionality.

Understanding the Basics of 3 Core Cable Specifications and Applications

When selecting a 3 core cable for electrical projects, understanding its specifications is crucial. These cables typically contain three conductors: live, neutral, and earth. This configuration ensures safety and optimal performance in various applications. According to industry standards, a 1.5mm² cable is suitable for lighting, while a 2.5mm² cable is often required for power sockets.

Installation practices can vary greatly. Improper sizing of cables can lead to energy losses or even potential hazards. A report from the International Electrotechnical Commission suggests that up to 30% of electrical inefficiencies stem from incorrectly specified cables. It highlights the importance of assessing factors like current rating, voltage drop, and environmental conditions.

When assessing applications, consider both residential and commercial needs. For instance, outdoor installations require cables with enhanced insulation. Choosing the right sheath material is also key. Some cables may struggle in extreme temperatures or moisture. It's an area where one can improve understanding before making a decision. Ensure to examine all parameters before finalizing the choice.

Key Factors to Consider When Selecting 3 Core Cables for Electrical Projects

Choosing the right 3 core cable is crucial for any electrical project. There are several key factors to consider. First, assess the cable’s current rating. This ensures safety and efficiency. Pay attention to the ampacity of the cable. It must match the electrical load you plan to use.

Next, consider the insulation type. Different materials protect against varying environmental conditions. For instance, PVC insulation is common for general purposes. However, rubber insulation is better for outdoor use. Understand the environment where the cable will be installed.

Cable length is another important factor. Longer cables may cause voltage drops. This can lead to inefficient performance or overheating. Always measure the distance accurately. Lastly, think about flexibility and installation ease. Some cables are stiff and hard to work with. A balance between durability and flexibility is essential.

Comparing Different Types of 3 Core Cables: Copper vs. Aluminum Conductors

When choosing the right 3 core cable, the conductor material plays a crucial role. Copper and aluminum are the two main types. Copper conductors are well-known for their excellent conductivity. This makes them a popular choice for many electrical projects. They also have high tensile strength, which makes them durable.

On the other hand, aluminum conductors are lighter and often more affordable. However, they have a lower conductivity compared to copper. This means that, for longer distances, aluminum cables may need to be thicker to carry the same current. Some may find it challenging to determine which conductor suits their project best.

Tips: Always consider the length of your cable run. If it's long, copper may be worth the investment. Also, think about the overall weight requirements. Heavier cables might not be ideal for all installations. It’s essential to weigh the pros and cons of both materials, keeping your specific project needs in mind. Some installations might benefit from the cost-effectiveness of aluminum, while others might require the reliability of copper. Remember, the choice isn't just about price; it's about performance and safety too.

Industry Standards and Regulations for 3 Core Cable Usage and Safety

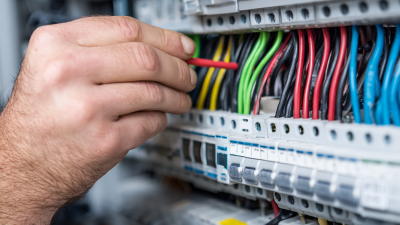

When selecting a 3 core cable, understanding the industry standards and regulations is essential. These regulations ensure safety and efficiency in electrical projects. According to the International Electrotechnical Commission (IEC), 3 core cables must comply with safety standards like BS 7671 for installation in the UK. This standard specifies the cable's insulation and conductive properties, ensuring they can handle the necessary loads without risk.

Tips: Always check for certification marks on cables. This guarantees compliance with safety standards.

Using cables manufactured to these regulations can lower the risk of electrical fires. The National Fire Protection Association (NFPA) states that improper wiring was a factor in around 35% of electrical fires. It's crucial to insist on quality materials.

Tips: Evaluate cable specifications against local codes. Research local amendments to ensure compliance.

Not all 3 core cables are equal. Some might not meet the needed capacity for your projects. Professional guides often highlight differences in insulation types and conductor sizes. Without careful selection, you may face performance issues.

Tips: Consult an expert when in doubt about cable specifications. It's an investment in safety and reliability.

Calculating the Correct Ampacity for Your 3 Core Cable Choices

Selecting the right 3 core cable for electrical projects involves careful consideration of ampacity. Ampacity refers to the maximum current a cable can handle safely. This is crucial to prevent overheating and electrical failures. Understanding the load requirements for your project is essential. Calculate the total amperage that your devices or systems will draw. This number helps in choosing the appropriate cable size.

Factors affecting ampacity include cable insulation type, ambient temperature, and installation conditions. For instance, a cable installed in a conduit may have a different ampacity than one in open air. It’s also important to consider the environment. Moist or hot areas can impact the cable's performance. If you underestimate the required ampacity, you risk damaging your equipment or creating safety hazards.

Also, remember that using a cable with too high a rating can be wasteful. While a thick cable may seem safer, it can lead to unnecessary costs. Balancing safety and cost is key. This is an area where many projects can falter. The choice of 3 core cable should not be taken lightly. Each detail matters significantly.

Related Posts

-

Exploring the Role of Cable Suppliers in Sustainable Energy Solutions

-

Understanding the Importance of Electric Cable Wire in Modern Technology

-

What is Wire and Cable and How Are They Used in Everyday Applications?

-

Understanding the Benefits and Uses of Romex Wire in Modern Electrical Installations

-

Top 10 Uses of Thermocouple Wire in Industrial Applications

-

Why is Power Wire Essential for Electrical Safety and Efficiency?