How to Choose the Right Soow Cable for Your Electrical Needs?

Choosing the right SOOW cable for your electrical needs can be daunting. There are various factors to consider. SOOW cables are versatile and used in many applications. They are known for their durability and flexibility.

When selecting a SOOW cable, think about the environment where it will be used. Will it face extreme temperatures or moisture? These details matter. You must also consider the cable's amperage rating. This will impact how the cable performs under load.

However, it’s not just about specifications. Reflect on your specific requirements. Sometimes, the most popular choice isn't the best one for your needs. Understand your demands fully. Doing so will save you time and potential issues in the future.

Understanding Soow Cable Specifications and Types

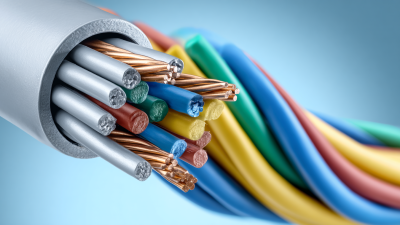

When selecting Soow cables, understanding their specifications is crucial. Soow cables are designed for flexible electrical connections in various environments. They feature durable insulation and are resistant to moisture and chemicals. This makes them suitable for outdoor use. Their ratings vary, so it's essential to match them with your project's requirements.

Tips: Always check the voltage rating before purchasing. Ensure the ampacity meets your needs. Different installations may require different conductor sizes.

Soow cables come in various types, each suited for specific tasks. Some have rubber jackets for extra protection. Others have an environmentally resistant design. Choose a type based on your setting and the level of exposure. Mistakes can happen. Not all cables will perform well under every condition.

Tips: Inspect cables for wear and tear regularly. Don't assume one type fits all. Test the flexibility of the cable before installation. Flexibility matters in tight spaces or bends.

Evaluating the Electrical Load Requirements for Your Project

When evaluating electrical load requirements for your project, precision is crucial. Understanding the specific needs dictates the type of Soow cable to choose. According to the National Electric Code (NEC), assessing the total load helps ensure safety and efficiency. Overloading can lead to overheating and potential failures. Accurate calculations prevent these hazards.

Take a closer look at the amperage draw of electrical devices. For instance, a three-phase motor may require a different gauge than a standard residential appliance. The NEC suggests using a 10% safety factor for unexpected surges. This buffer helps accommodate additional loads or temporary spikes. Many underestimate the importance of this factor.

Another consideration is the environment where the cable will be used. Is it exposed to moisture or chemicals? These factors can affect cable insulation performance. The industry standard indicates that environmental conditions can reduce cable lifespan by up to 30%. Be diligent in researching your specific conditions to avoid costly mistakes later.

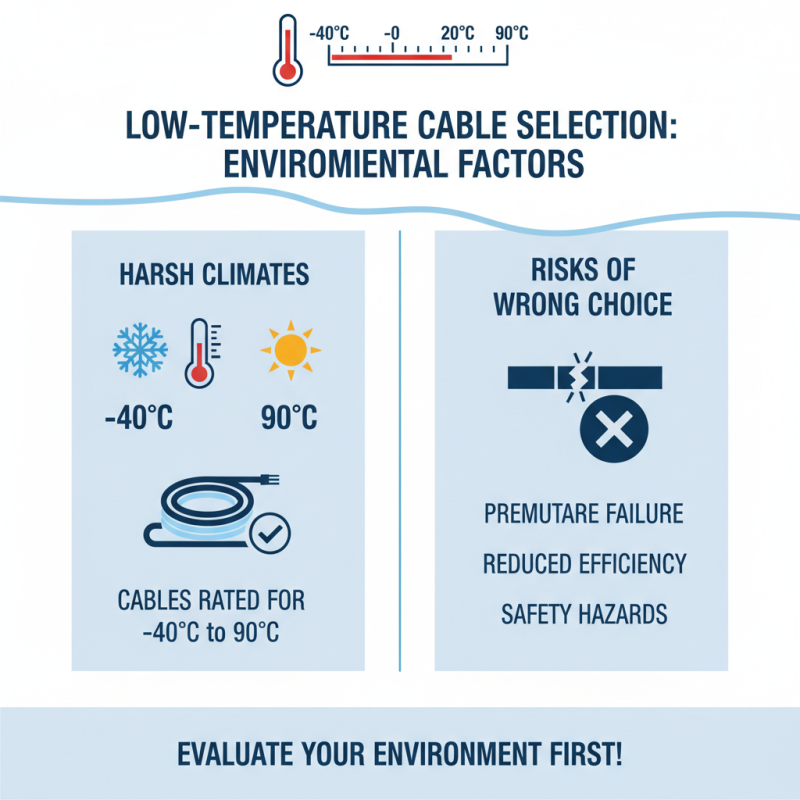

Identifying Environmental Factors Affecting Cable Performance

When selecting Soow cables, environmental factors play a critical role in performance. Extreme temperatures can significantly impact cable efficiency. For example, cables rated for -40°C to 90°C are often necessary in harsh climates. If cables cannot handle extreme conditions, they may fail prematurely. It’s crucial to evaluate your specific environment before making a choice.

Moisture levels are another key concern. High humidity or exposure to water can lead to insulation breakdown over time. According to industry reports, around 30% of cable failures are attributed to environmental moisture. Proper insulation and coatings are vital in these situations. Ignoring moisture risks can lead to safety hazards and costly replacements.

Moreover, mechanical stress is an often-overlooked factor. Cables subjected to frequent movement or abrasions require enhanced durability features. Research indicates that nearly 50% of failures occur due to physical damage. Assessing how and where cables will be used is essential for longevity. Without this, your investment may not yield the expected results.

Ensuring Compatibility with Connectors and Accessories

Choosing the right SOOW cable is crucial for ensuring safety and functionality. One major consideration is compatibility with connectors and accessories. Incompatible connections can lead to electrical failures, overheating, or even fires. According to industry reports, over 20% of electrical incidents stem from poor connector match-ups. This statistic highlights the significance of selecting the correct cable type that aligns with existing connectors.

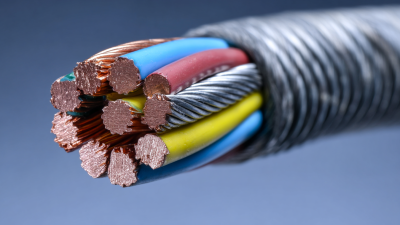

When assessing compatibility, inspect the cable specifications. Look for the conductor size, insulation type, and voltage rating. For instance, a 10-gauge SOOW cable supports a higher ampacity but must match corresponding connectors. It’s essential to choose accessories designed for similar environmental conditions. An incongruous combination can lead to degradation over time. This is often overlooked, yet it can significantly impact the overall performance and safety of electrical installations.

Additionally, consider the intended application. Outdoor settings may require different ratings than indoor uses. Some cables may be rated for oil resistance, while others aren't. Ensure all parts in the system can handle expected loads and conditions. Not all cables are created equal, and mismatched components can lead to unsatisfactory results. Always scrutinize and reflect on each choice made in the process; a small oversight can cause major risks.

How to Choose the Right Soow Cable for Your Electrical Needs? - Ensuring Compatibility with Connectors and Accessories

| Cable Type | Conductor Size (AWG) | Voltage Rating (V) | Max Operating Temperature (°C) | Water Resistance | Recommended Connectors |

|---|---|---|---|---|---|

| SOOW Cable | 16 | 600 | 90 | Yes | NEMA L14-20P |

| SOOW Cable | 12 | 600 | 90 | Yes | NEMA L6-30P |

| SOOW Cable | 10 | 600 | 90 | Yes | NEMA L15-30P |

| SOOW Cable | 8 | 600 | 90 | Yes | NEMA L21-30P |

Considering Safety Standards and Regulations for Soow Cables

When selecting the right SOOW cable, understanding safety standards and regulations is crucial. SOOW cables are designed for outdoor and industrial use, which means they must comply with strict safety requirements. According to the National Electrical Code (NEC), these cables need to withstand harsh environmental conditions. In fact, various reports indicate that improper installation can lead to accidents. It's essential to choose cables that meet or exceed these standards for your specific application.

Tips: Always check for certifications! Look for UL listing and other relevant approvals on your cable. This ensures reliability and safety.

Another important factor is the ampacity rating of SOOW cables. Overloading cables can cause overheating and lead to potential hazards. According to industry studies, cables should be chosen based on the expected load. A mismatch between capacity and usage often results from a lack of awareness. Regularly reviewing load requirements is necessary to prevent accidents.

Tips: Consider the environment. Factors such as temperature and exposure to chemicals can influence cable performance. Regular maintenance checks can reveal signs of wear and tear.

Comparison of SOOW Cable Types by Ampacity

Related Posts

-

Top 10 Benefits of Using Soow Cable for Your Electrical Wiring Needs

-

Top Wire Connectors: Choosing the Best Types for Your Projects

-

What is Armoured Cable? Understanding Its Types, Benefits, and Applications

-

Top Types of Cable Wire You Need to Know for Effective Wiring Solutions

-

2025 Top 10 Marine Cable Innovations Transforming Global Connectivity

-

2026 Best 3 Core Cable Selection for Your Electrical Projects?