How to Choose the Right Wire Suppliers for Your Business Needs

In the dynamic world of manufacturing, choosing the right wire suppliers is critical. Experts suggest a careful evaluation of potential partners. John Smith, a wire industry veteran, once stated, "Quality wire suppliers can make or break your project." This highlights the importance of selection.

Finding suitable wire suppliers involves more than price comparison. It requires assessing quality, reliability, and service. A supplier’s ability to meet deadlines can be the difference between success and failure. Take the time to evaluate not just the product, but also their customer support. A single misstep in supplier choice can lead to significant setbacks.

Remember that not all suppliers will meet your expectations. Some may lack transparency in their processes, while others may fail in communication. Reflecting on past experiences can guide better choices. Choosing wire suppliers is not just a business decision; it’s a step towards your project's success.

Understanding Your Business Requirements for Wire Supplies

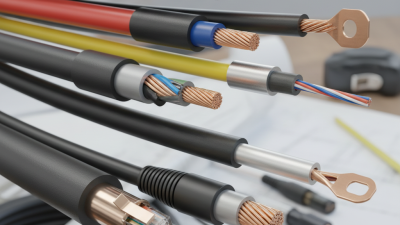

Understanding your business requirements for wire supplies is essential. Different industries have distinct needs based on application. Construction may require heavy-duty wires. Electronics typically use finer wiring for intricate circuits. Knowing the type of wire that suits your products can help you narrow down potential suppliers.

Quality matters greatly when selecting suppliers. However, it is not just about ratings. Sometimes, a lesser-known supplier offers exceptional quality and service. If you overlook smaller suppliers, you may miss great opportunities. It's important to evaluate their production processes, certifications, and customer feedback. Have they met compliance standards? Are their materials sourced responsibly?

Consider the scalability of suppliers as well. Startups may not need large quantities, while established businesses often require bulk supplies. It's a balancing act. Can your supplier accommodate growth? What happens in case of increased demand? These are questions that require your attention. Reflecting on these aspects helps ensure you make informed decisions regarding wire suppliers.

Evaluating the Quality Standards of Wire Suppliers

When selecting wire suppliers, quality standards are crucial. High-quality wires enhance product performance and durability. Look for suppliers that adhere to industry standards like ISO or ASTM. These certifications indicate a commitment to reliable production processes.

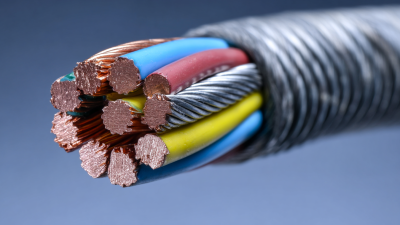

Examine the materials used in wire production. Quality metals and alloys greatly impact strength and longevity. Request technical specifications to understand the composition. Additionally, inquire about the supplier’s quality control processes. This includes inspections and testing procedures. A supplier that prioritizes testing is likely more trustworthy.

Consider customer feedback as well. Reviews can highlight whether a supplier consistently meets quality standards. However, be cautious. Not all reviews reflect true performance. Some may be biased. Engaging in direct discussions with suppliers can also reveal insights. Ask about their commitment to continuous improvement in quality. A supplier willing to adapt likely values long-term relationships with clients.

Comparing Pricing and Payment Terms Among Different Suppliers

When selecting wire suppliers, pricing and payment terms are crucial. According to recent industry data, prices can vary significantly. For instance, some suppliers offer premium products at a higher cost, while others provide basic options at lower rates. It's essential to analyze what fits your budget.

Understanding payment terms is equally vital. Many suppliers require upfront payments. Others offer net 30 or net 60 terms. These conditions can impact cash flow. If cash is tight, opting for suppliers with favorable payment terms may be beneficial. This flexibility can relieve financial stress for your business.

Tip: Always request quotes from multiple suppliers. Comparing is free. Look for hidden fees in pricing. Be wary of seemingly low costs that may come with additional charges. A good supplier values transparency. Reflecting on this aspect can lead to better supplier relationships. Balancing cost and terms can enhance your overall purchasing strategy.

Comparison of Pricing and Payment Terms Among Wire Suppliers

Assessing Supplier Reliability and Delivery Capabilities

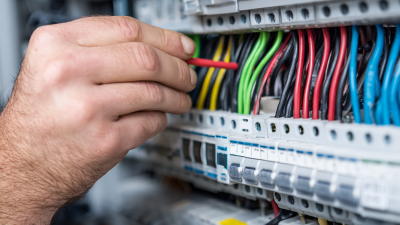

Choosing the right wire suppliers is crucial for any business. One key aspect is assessing their reliability and delivery capabilities. A reliable supplier ensures that you receive quality wires consistently. Check their track record. Look for customer reviews online. Unreliable suppliers often lead to delays, which can harm your operations.

**Tips:** Always ask for references. Speak to other clients about their experience. This insight can be invaluable. See if the supplier has long-term relationships with other businesses. Stability often indicates reliability.

Delivery capabilities are equally important. A supplier should meet your timelines. Investigate their logistics. Do they have a solid shipping process? Delays in deliveries can disrupt your projects.

**Tips:** Are they flexible with shipping options? Can they handle urgent requests? These questions can help you gauge their delivery efficiency. Remember, a supplier's commitment shows in their service. A thoughtful approach in selecting suppliers can save you headaches in the future.

Exploring Additional Services Offered by Wire Suppliers

When selecting wire suppliers, consider the additional services they offer. These services can significantly impact your production efficiency and overall costs. Some suppliers provide custom wire forms, which can be tailored to specific projects. This flexibility can save time and reduce waste. It's worth asking potential suppliers about their capabilities in customization.

Another essential service to evaluate is technical support. Suppliers who offer assistance with engineering problems can be invaluable. They can help troubleshoot issues and optimize your designs. Personalized consultations are often overlooked but can lead to better outcomes in your projects. If a supplier lacks this, reconsider their fit for your business.

In addition, think about logistics support. Reliable delivery schedules are crucial. Some suppliers may offer various shipping options or even inventory management. If they do not present robust logistics services, it might lead to delays. Investigating these aspects can improve your supply chain's reliability. Sometimes, suppliers may promise more than they can deliver. Thus, careful assessment is necessary.

Related Posts

-

2025 Guide to Choosing the Right Wire and Cable for Your Projects

-

2025 Top 5 Benefits of 4 Wire Systems for Enhanced Electrical Efficiency

-

The Ultimate Guide to Understanding Different Wire Connector Types for Your Projects

-

Top Electrical Connectors for Reliable Performance in Your Projects

-

What is Armoured Cable? Understanding Its Types, Benefits, and Applications

-

Understanding the Benefits and Uses of Romex Wire in Modern Electrical Installations