Why Are Electrical Connectors Essential for Reliable Electrical Connections?

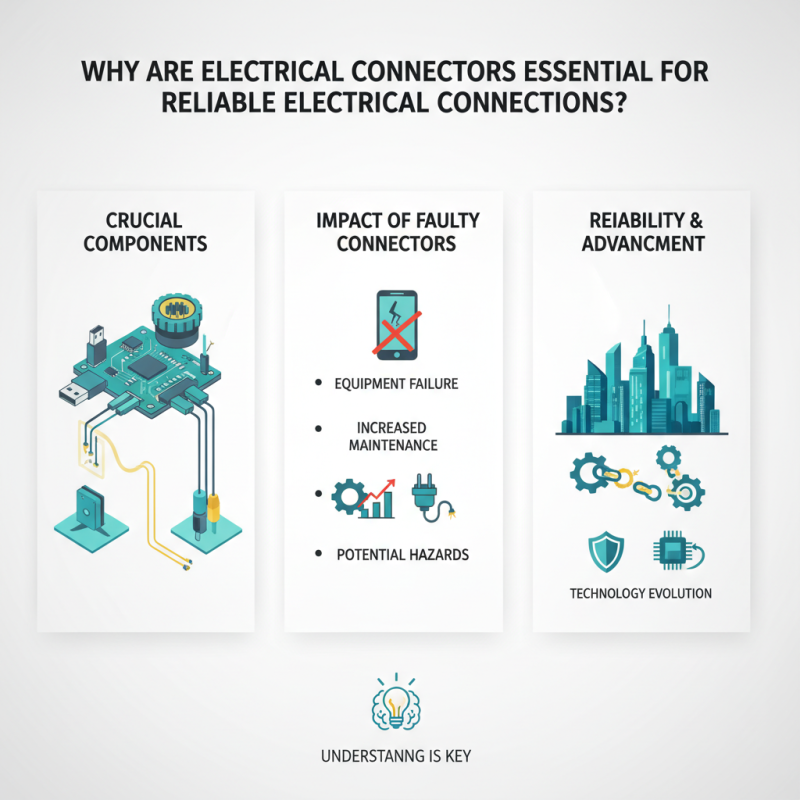

Electrical connectors are crucial components in modern electronic systems. They facilitate reliable electrical connections between various devices and circuits. The integrity of these connections directly affects performance and safety. Faulty connectors can lead to equipment failure, increased maintenance costs, and potential hazards.

Consider the everyday devices we rely on. A simple malfunction in an electrical connector can disrupt our smartphones, computers, or home appliances. It's easy to overlook these connectors, yet they play a vital role. Poorly designed or degraded connectors can create intermittent issues. These problems might be hard to identify, leading to frustrating experiences.

Reflecting on this, it's clear that understanding electrical connectors is essential. Awareness of their importance can guide us in choosing reliable products. As technology evolves, so too does the need for more advanced and durable electrical connectors. We must appreciate their significance in ensuring uninterrupted power flow and effective communication between devices.

The Definition and Function of Electrical Connectors

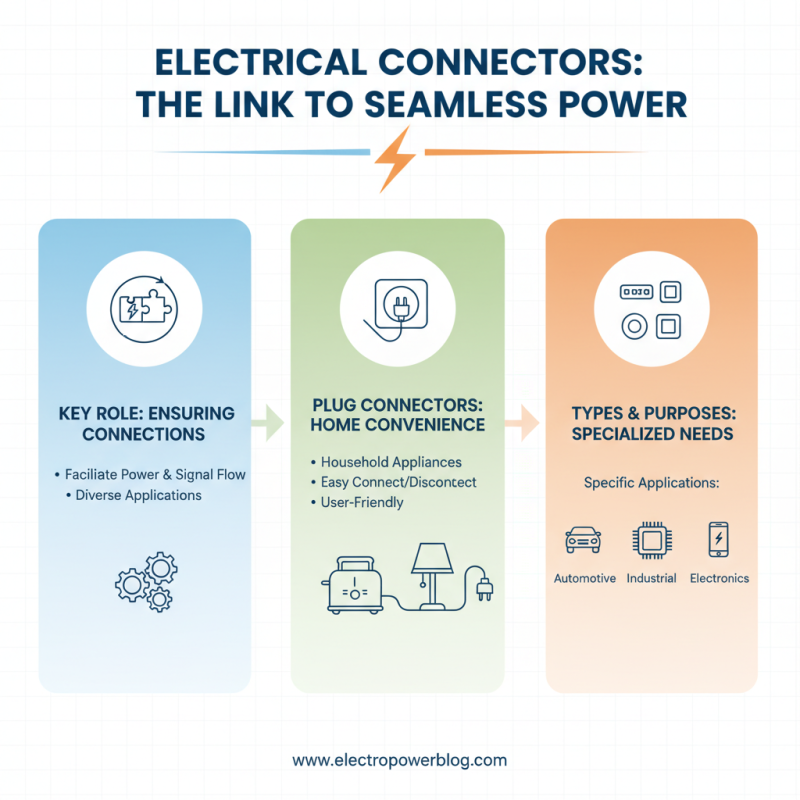

Electrical connectors play a crucial role in ensuring reliable electrical connections across various applications. These components are designed to establish a safe and efficient link between two or more electrical circuits. According to a recent industry report from MarketsandMarkets, the global electrical connectors market is projected to reach $XX billion by 2025, highlighting their growing importance in sectors like automotive and telecommunications.

Electrical connectors come in many types, each tailored for specific functions. They can be found in everyday items, from power adapters to complex machinery. It’s essential to choose the right connector for each application to prevent issues like overheating or signal loss. Failure in selecting the appropriate connector can lead to system downtime, which costs industries millions. In fact, research indicates that improper connections account for approximately 30% of electrical failures.

Tip: Always check compatibility before installation. Use connectors that match the voltage and amperage requirements of your system.

With the rise of automation and IoT, the demand for robust connectors will only increase. Yet, many designs still face challenges, such as material degradation over time. In some applications, connectors can corrode, leading to unreliable performance. Reflecting on these considerations is crucial for ensuring long-term reliability.

Tip: Regular maintenance and inspection can help mitigate these risks. Periodically testing connections will lead to better performance.

Types of Electrical Connectors and Their Applications

Electrical connectors play a pivotal role in ensuring seamless electrical connections across various applications. Different types of electrical connectors serve specific purposes, highlighting their significance. For instance, plug connectors are widely used in household appliances. They facilitate easy connection and disconnection for user convenience.

Another common type is the terminal block connector. These are often found in industrial settings where multiple wires need to be connected securely. They provide a neat and organized way to manage electrical connections. Despite their importance, miswiring or incorrect connections can lead to failure.

Circular connectors are also essential in specialized settings, such as in aerospace or automotive industries. They excel in providing durability and resistance to harsh environments. However, their complexity sometimes leads to installation errors. Understanding the nuances of each type is crucial for reliability. Users often overlook the need for regular maintenance and checks, as neglect can increase the risk of connection failures.

Importance of Reliability in Electrical Connections

Reliability in electrical connections is crucial for countless applications. A simple connector failure can lead to significant issues. Imagine an industrial machine halting due to a loose wire. Or a critical medical device malfunctioning because of a poor connection. These scenarios emphasize the need for dependable electrical connectors.

Consider environments with high vibration or extreme temperatures. Connectors must withstand such challenges. Yet, not all connectors perform well under these conditions. Some may seem fine at a glance but fail when tested. It’s essential to choose connectors designed for specific environments. Neglecting to do so can result in costly downtime and safety hazards.

Moreover, regular maintenance plays a vital role. Inspections can identify wear and tear before problems arise. However, many overlook this step. They assume everything is fine until an issue occurs. This approach is risky. Proactive measures can help ensure ongoing reliability and performance in every electrical connection.

Factors Influencing Connector Performance and Durability

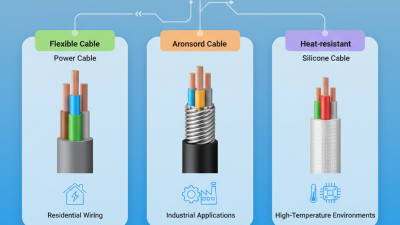

Electrical connectors play a crucial role in ensuring reliable connections. Several factors affect their performance and durability. The materials used in connectors can greatly impact their longevity. For instance, metal types can influence conductivity and resistance to corrosion. A low-quality metal may lead to failure over time. Some connectors may not handle high temperatures well, leading to melting or degradation.

Environmental factors also play a part. Humidity can cause oxidation, weakening the connection. Additionally, vibrations can loosen connectors, leading to intermittent failures. In outdoor applications, exposure to UV light can deteriorate plastic parts. Users often overlook these factors, which can lead to unexpected issues.

Design flaws can introduce weaknesses as well. For example, poor contact design can result in inconsistent electrical flow. Repeated plugging and unplugging may wear out connectors faster than expected. It’s essential to reflect on these aspects when selecting connectors for specific applications. By understanding these influencing factors, we can make better choices for electrical connections.

Factors Influencing Connector Performance and Durability

Best Practices for Selecting and Maintaining Electrical Connectors

Electrical connectors play a crucial role in ensuring reliable electrical connections across various applications. Selecting the right connector can significantly impact performance. According to industry reports, improper connector usage can lead to failures in up to 30% of electrical systems. The right connector can enhance durability and reduce maintenance costs.

When choosing connectors, consider materials, size, and environmental factors. For example, connectors used in marine environments should resist corrosion. A recent study highlighted that connectors made from high-grade metals increased lifespan by 50%. It's essential to evaluate the specific demands of your application.

Maintaining connectors is equally vital. Regular inspections can prevent major issues. Wear and tear often go unnoticed. Research shows that 20% of electrical failures are related to poor maintenance practices. Implementing a routine check can mitigate risk. Keeping connections clean and secure ensures optimal performance over time.

Related Posts

-

Top Electrical Connectors for Reliable Performance in Your Projects

-

Maximizing Safety and Efficiency: The Essential Guide to Choosing Electrical Wire Connectors in 2023

-

Top Types of Cable Wire You Need to Know for Effective Wiring Solutions

-

How to Choose the Right 3 Core Cable for Your Electrical Projects

-

Top 10 Uses of Thermocouple Wire in Industrial Applications

-

Top 3 Core Cable Types You Need to Know for Your Electrical Projects