Exploring the Essential Role of Power Wires in Modern Electrical Systems

In today's rapidly evolving technological landscape, the significance of power wires in modern electrical systems cannot be overstated. As reported by the International Electrotechnical Commission (IEC), the global market for power cables is expected to reach over $230 billion by 2026, driven by the increasing demand for reliable and efficient power distribution.

Power wires serve as the backbone for a multitude of applications, from residential wiring to complex industrial systems, ensuring safe and efficient transfer of electricity. The advent of smart technologies and renewable energy sources further amplifies the critical role of power wires, necessitating robust solutions that can handle higher loads and improved performance.

This article delves into how power wires are essential components in modern electrical infrastructure, highlighting their diverse applications and the impact they have on enhancing system reliability and energy efficiency.

Understanding the Importance of Power Wires in Electrical Systems

Power wires are the backbone of modern electrical systems, responsible for delivering electricity from one point to another, ensuring that our devices function smoothly. Their importance cannot be overstated, as they are critical for safety, efficiency, and reliability. A well-designed electrical system relies heavily on high-quality power wires to minimize energy loss and protect against overheating, which can lead to fire hazards.

**Tips:** When choosing power wires, always consider the wire gauge appropriate for your specific application; a thicker wire can handle more current and reduce resistance. Additionally, regularly inspect your wiring for any signs of wear or damage, as early detection can prevent larger issues down the line.

In addition to safety, quality power wires contribute to optimal performance. Poor-quality wires can introduce electrical resistance, leading to voltage drops that affect equipment performance. Selecting the right insulation material is also crucial, as it determines the wire's ability to withstand environmental factors such as moisture and temperature fluctuations.

**Tips:** Ensure that your power wires have the correct insulation rating for their intended environment. It’s also wise to consult with a professional electrician when making significant upgrades or repairs to your electrical system to ensure compliance with safety regulations and best practices.

Understanding the Importance of Power Wires in Electrical Systems

This chart illustrates the increasing usage of different types of power wires in modern electrical systems over the past decade. The data highlights the importance of selecting the appropriate power wire for various applications to ensure efficiency and safety.

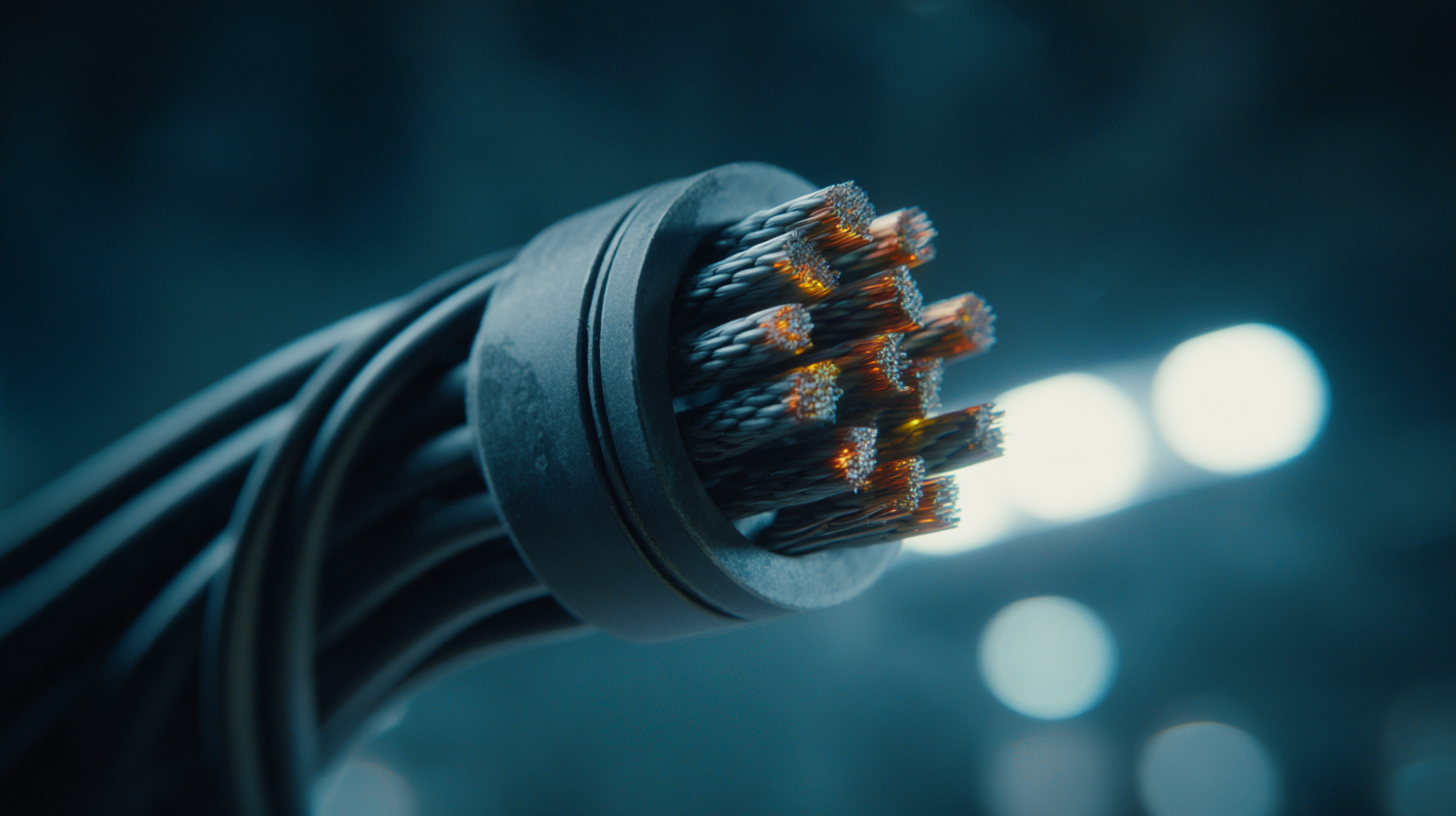

Identifying Different Types of Power Wires and Their Uses

Power wires are integral to modern electrical systems, serving as conduits for electricity to flow from power sources to various devices and appliances. Understanding the different types of power wires and their specific applications is crucial for any electrical project, whether residential or industrial. Among the most common types are copper and aluminum wires. According to a recent industry report by MarketsandMarkets, the global market for power cables is projected to reach $200 billion by 2025, indicating a growing demand for efficient wiring solutions.

Copper wires, known for their excellent conductivity and flexibility, are commonly used in residential wiring and electronics. In contrast, aluminum wires, while lighter and more cost-effective, are often utilized in overhead power lines and larger installations. Each type has its advantages and disadvantages based on factors such as conductivity, cost, and application environment, making it essential to choose the right wire type for specific needs.

**Tips:** When selecting power wires, consider factors such as the electrical load, installation environment, and local codes. Regularly inspect wiring systems for wear and damage to ensure safety and efficiency. Additionally, using the correct gauge wire will minimize energy loss and enhance performance in any electrical system.

Step-by-Step Guide to Selecting the Right Power Wires for Projects

When embarking on any electrical project, selecting the right power wires is crucial for ensuring safety, efficiency, and reliability. The first step in this process involves understanding the specific needs of your project.

Consider factors such as the voltage requirements, current capacity, and whether the wires need to be flexible or rigid.

It’s essential to assess the environment in which the wires will be used—whether they will be exposed to harsh weather conditions, chemicals, or physical abrasion.

Once the requirements are clear, the next step is to choose the appropriate wire gauge. A lower gauge number indicates a thicker wire capable of carrying more current, while a higher gauge represents a thinner wire.

Using wires that are too thin can lead to overheating, while overly thick wires can be unnecessarily costly and inflexible. Additionally, be mindful of insulation types; proper insulation is vital in protecting wires from damage and preventing electrical hazards.

By following these guidelines, you can ensure that your electrical system operates smoothly and safely.

Best Practices for Installing and Maintaining Power Wires

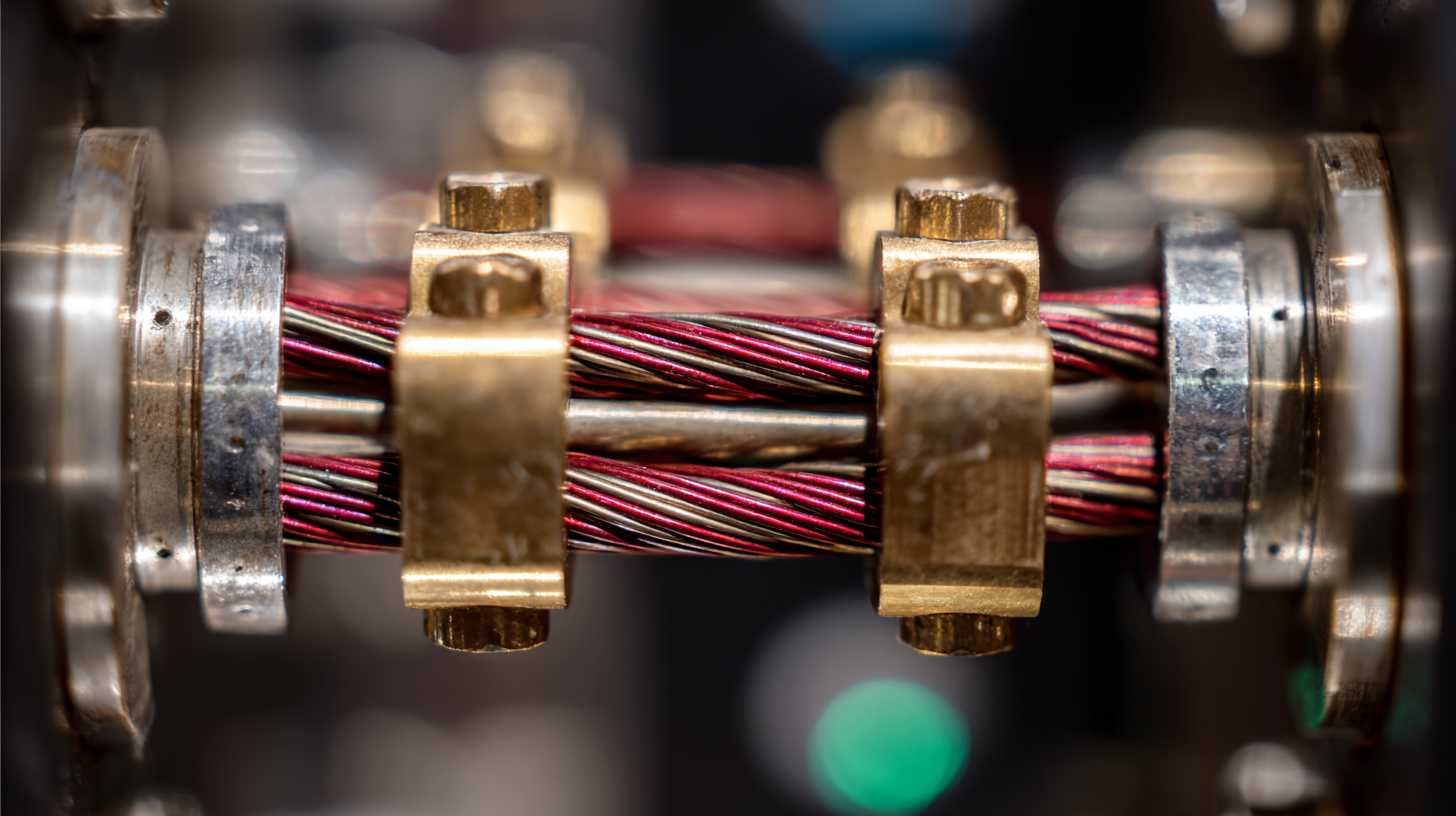

The installation and maintenance of power wires are critical to ensuring the efficiency and reliability of modern electrical systems. Proper techniques should be employed to ensure that power wires are installed in accordance with safety standards and operational requirements. This includes selecting the appropriate cable types and sizes based on the intended load and environmental factors. Additionally, implementing proper routing and securing methods, such as cable cleats, can significantly reduce the risk of mechanical stress and damage to the wires, thereby extending their lifespan.

The installation and maintenance of power wires are critical to ensuring the efficiency and reliability of modern electrical systems. Proper techniques should be employed to ensure that power wires are installed in accordance with safety standards and operational requirements. This includes selecting the appropriate cable types and sizes based on the intended load and environmental factors. Additionally, implementing proper routing and securing methods, such as cable cleats, can significantly reduce the risk of mechanical stress and damage to the wires, thereby extending their lifespan.

Regular maintenance practices are equally important in preserving the integrity of electrical systems. This encompasses routine inspections for signs of wear and corrosion, as well as ensuring that connections remain tight and secure over time. By adopting a proactive approach to maintenance and scheduling repairs promptly, organizations can mitigate the risk of power outages and enhance the overall performance of their electrical infrastructure. As the demand for electrification grows, particularly in sectors like rail transportation, the emphasis on effective power wire management will continue to rise, contributing to a more sustainable and efficient energy landscape.

Safety Considerations When Working with Power Wires in Electrical Systems

When working with power wires in electrical systems, safety should always be a top priority. Improper handling of power wires can lead to serious accidents, including electric shocks, fires, and equipment damage. It is crucial to understand the voltage levels and current ratings of the wires you are working with, as each type poses different risks. Always ensure that the power supply is turned off and locked out before beginning any work on electrical systems to avoid accidental energization.

**Tips:** Use insulated tools and wear personal protective equipment (PPE) such as gloves and goggles to protect yourself from potential hazards. Additionally, familiarize yourself with the emergency procedures in case of an accident, and always have a first aid kit on hand.

Another critical aspect is the proper installation and maintenance of power wires. Ensure that all connections are secure and that the wires are installed according to the manufacturer’s specifications and local codes. Regular inspections can help identify wear and damage early on, preventing malfunctions or dangerous situations down the line.

**Tips:** Keep your workspace organized to minimize risks of trips and falls, and label all circuits clearly to avoid confusion during maintenance. Always adhere to the principle of "measure twice, cut once" to ensure accuracy and safety in your work.