10 Essential Tips for Choosing the Right Automotive Wire for Your Needs

When embarking on any automotive project, selecting the right automotive wire is crucial for ensuring safety, efficiency, and durability. Automotive wire serves as the backbone of electrical systems in vehicles, facilitating the necessary flow of electricity for various components, from lights and sensors to power distribution and communication systems. However, with the myriad of options available on the market, choosing the appropriate automotive wire can be a daunting task for both professionals and enthusiasts alike.

Understanding the key factors that influence your selection is essential for achieving optimal performance. Factors such as wire gauge, insulation type, temperature ratings, and application requirements must all be considered to ensure compatibility and reliability. The right automotive wire not only enhances the functionality of your vehicle but also minimizes the risk of electrical failures or hazards. This article will guide you through ten essential tips that will help you navigate the complexities of selecting automotive wire, ensuring that you make an informed and effective choice tailored to your specific needs.

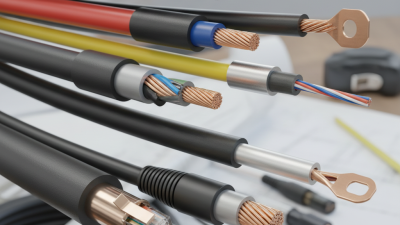

Understanding Types of Automotive Wire for Various Applications

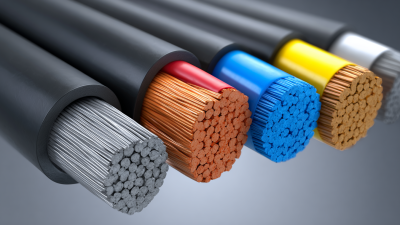

When selecting the right automotive wire, it's crucial to understand the various types available and their specific applications. Automotive wiring systems primarily use copper and aluminum wires, with copper being the preferred choice due to its superior conductivity, flexibility, and durability. According to a 2022 report by the International Wire and Cable Technical Conference, approximately 60% of automotive failures can be traced back to wiring issues, highlighting the importance of selecting high-quality wire for reliable vehicle performance.

Different applications within vehicles demand particular wire types. For instance, primary electrical systems typically utilize stranded copper wire due to its better flexibility, which is essential for the movement and vibration within an engine compartment. In contrast, for applications requiring resistance to extreme heat, such as in proximity to exhaust systems, high-temperature silicone wire is recommended. Additionally, low-voltage lighting circuits often employ smaller gauge wires, while high-current applications, like battery cables, usually require larger gauge wires to handle the increased load efficiently. Understanding these distinctions is vital for ensuring the efficacy and safety of automotive electrical systems, as proper wire selection directly impacts vehicle reliability and longevity.

Identifying Key Specifications When Selecting Automotive Wire

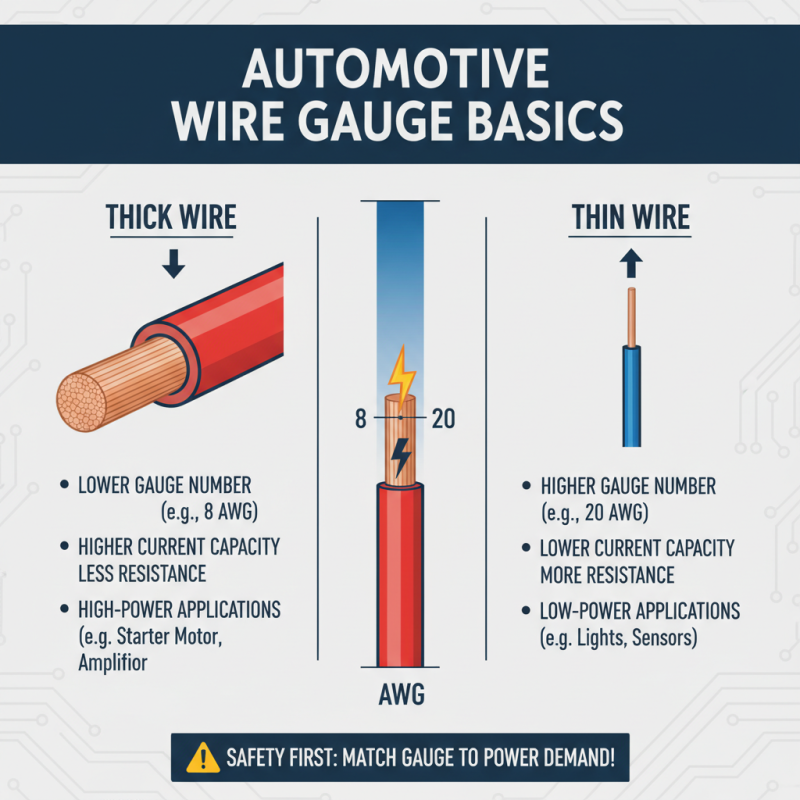

When selecting automotive wire, understanding key specifications is crucial to ensure optimal performance and safety. One of the primary considerations is the wire gauge, which determines the wire's ability to carry current. Thicker wires, indicated by lower gauge numbers, can handle higher loads without overheating, making them suitable for high-power applications. Conversely, thinner wires are better for lower power requirements. Always consult the vehicle's specifications or wiring diagrams to determine the appropriate gauge for the intended use.

Another important factor is the insulation type, which protects the wire from environmental damage, heat, and electrical interference. Common insulation materials include PVC, which is flexible and resistant to wear, and cross-linked polyethylene (XLPE), offering superior heat resistance. Additionally, examining the temperature rating of the insulation ensures that the wire can handle the operational temperatures it will encounter in the automotive environment. It is also vital to assess the wire’s resistance to abrasion, chemicals, and moisture, especially in areas exposed to harsh conditions, ensuring long-lasting performance and reliability.

10 Essential Tips for Choosing the Right Automotive Wire for Your Needs

| Tip | Key Specification | Description |

|---|---|---|

| 1. Determine Wire Gauge | AWG Size | Select the appropriate American Wire Gauge based on amperage and distance. |

| 2. Assess Temperature Range | Temperature Rating | Ensure the wire insulation can withstand the operating temperature in your vehicle. |

| 3. Check Insulation Material | Material Type | Choose from PVC, XLPE, or other materials based on durability needs. |

| 4. Evaluate Flexibility | Stranding | Look for stranded wire for applications requiring movement or flexibility. |

| 5. Inspect Wire Length | Length Needed | Calculate the necessary length and allow for extra for routing. |

| 6. Determine Voltage Rating | Voltage Capacity | Select wire that can handle the voltage of your automotive system. |

| 7. Review Chemical Resistance | Resistance Level | Consider exposure to oils, gasoline, and other chemicals when choosing wire. |

| 8. Choose Color Coding | Wire Color | Use appropriate color coding to enhance identification and safety. |

| 9. Consider Environmental Factors | Environmental Rating | Select wire rated for outdoor or humid conditions if needed. |

| 10. Verify Compliance Standards | Industry Standards | Ensure the wire complies with SAE, ISO, or other relevant standards. |

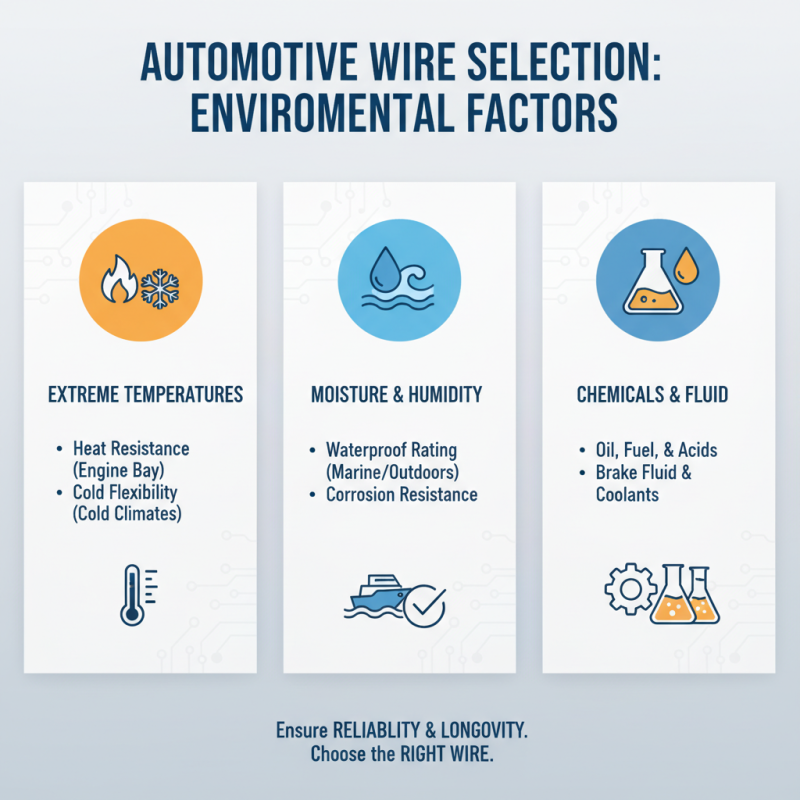

Evaluating Environmental Factors Affecting Wire Performance

When selecting automotive wire, environmental factors play a crucial role in determining the wire's performance and longevity. Exposure to extreme temperatures, moisture, and chemicals can significantly impact wire insulation and conductivity. For instance, wires used in harsh climates must be resistant to both heat and cold, ensuring reliability under fluctuating temperatures. Similarly, if the wire will be exposed to moisture, such as in marine applications, selecting wires with appropriate waterproof ratings and corrosion resistance is essential.

Tip: Always consider the specific environmental conditions where the wire will be installed. If it’s in an area with high humidity or potential water exposure, opting for wires with robust insulation designed for such environments can help prevent failures over time.

Another critical aspect to evaluate is the presence of potential chemicals, such as oils, fuels, and cleaning agents, that can degrade the wire materials. Automotive environments are susceptible to various fluids, making chemical resistance an imperative factor in your selection.

Tip: Conduct a thorough assessment of your vehicle’s expected operating conditions and select wire that can withstand the specific chemicals it may encounter. Choosing the right wire not only ensures safety but also enhances the longevity and efficiency of your automotive electrical systems.

Assessing Wire Gauge and Its Importance in Electrical Systems

When selecting automotive wire, understanding wire gauge is crucial for ensuring the efficiency and safety of electrical systems. Wire gauge refers to the diameter of the wire, which influences its current-carrying capacity, resistance, and overall performance. A thicker wire, typically represented by a lower gauge number, can handle higher currents without overheating, making it suitable for high-power applications. Conversely, a thinner wire has a higher gauge number and is appropriate for low-power circuits. Therefore, assessing the appropriate wire gauge based on the application's electrical demands is essential to prevent potential failures or hazards.

Additionally, the wire gauge affects the voltage drop across the wire over extended distances. A larger voltage drop can lead to inadequate power supply to various components, impairing functionality. It's important to consider the length of the wire run as well; for longer distances, a thicker wire may be necessary to minimize resistance and maintain optimal performance. Proper gauge selection not only contributes to the reliability of the vehicle’s electrical system but also ensures compliance with safety standards, reducing the risk of electrical fires or component damage. Choosing the right automotive wire starts with a thorough understanding of wire gauge and its implications for the entire system.

Ensuring Compliance with Automotive Standards and Regulations

When selecting automotive wire, ensuring compliance with automotive standards and regulations is essential for both safety and performance. Automotive wiring must meet stringent criteria to withstand the unique challenges posed by the environment inside a vehicle. Understanding the necessary certifications, such as SAE (Society of Automotive Engineers) standards, ensures that the wire you choose can handle high temperatures, resist abrasion, and provide adequate insulation against electrical faults.

Tip: Always check the wire's rating for temperature and voltage. Different applications may require varying degrees of conductivity and heat resistance. For example, the wiring used in engine compartments needs to tolerate higher temperatures compared to that in the passenger compartment. This not only ensures longevity but also prevents potential electrical failures that could result in hazardous situations.

In addition to meeting regulatory standards, consider the wire’s material composition. Copper is a popular choice due to its excellent conductivity, while options like aluminum can offer weight savings. However, ensure that any material used complies with industry regulations specific to automotive applications.

Tip: When in doubt, consult with industry professionals or reference regulatory guidelines. Connecting with experts can provide insights that ensure your wire selection aligns with both safety requirements and functionality, ultimately leading to a more reliable automotive system.

10 Essential Tips for Choosing the Right Automotive Wire for Your Needs

This chart illustrates the importance of various factors when selecting automotive wire, reflecting the compliance with automotive standards and regulations.

Related Posts

-

Essential Automotive Cable Maintenance Tips for a Smooth Ride

-

Exploring the Advantages of 4 Core Cable in Modern Electrical Installations and Its Impact on Efficiency

-

Understanding the Importance of Electric Cable Wire in Modern Technology

-

Top Types of Cable Wire You Need to Know for Effective Wiring Solutions

-

2025 Guide to Choosing the Right Wire and Cable for Your Projects

-

How to Choose the Right Welding Cable for Your Projects in 2025