10 Essential Tips for Choosing the Right MC Cable for Your Projects?

Choosing the right MC cable is crucial for any electrical project. The wrong choice can lead to safety hazards and costly mistakes. According to industry reports, improper cable selection contributes to over 30% of electrical failures. This highlights the importance of making informed decisions.

MC cables, or metal-clad cables, serve a significant role in both commercial and residential settings. They offer durability and protection against environmental hazards. However, selecting the appropriate type can be a challenge. Factors such as installation environment and load requirements must be carefully evaluated.

Many professionals overlook these key points, often leading to issues down the line. Quality matters, and not all MC cables are created equal. It’s essential to consult product specifications and industry standards. Understanding the unique attributes of each cable type can make a significant difference in project success.

Understanding MC Cable: Definitions and Key Features

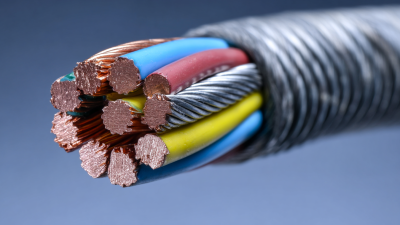

When selecting MC cable, understanding its definitions and key features is crucial. MC cable stands for "Metal Clad" cable. It is made of insulated conductors surrounded by a metal sheath. This design protects the wires from damage and reduces the risk of electrical hazards. The metal cladding also provides excellent grounding, making it a safe choice for various applications.

MC cables come in different sizes and configurations. They might have multiple conductors or just one. The choice depends on the specific needs of your project. It's important to consider the environment where the cable will be installed. For example, wet locations require special types of MC cables. Not all cables are created equal. Some may not withstand extreme temperatures or moisture. Assessing these factors can save you from future issues.

Don't overlook the importance of local codes and regulations. They often dictate what type of MC cable you can use. Ignoring these guidelines could lead to problems. Additionally, improper installation is another common pitfall. Lack of knowledge about cable stripping or securing can affect performance. Always ensure that the installation adheres to safety standards.

10 Essential Tips for Choosing the Right MC Cable for Your Projects

This chart displays the importance rating of various factors to consider when selecting MC cable for your projects. The ratings range from 1 to 10, with 10 being the most important.

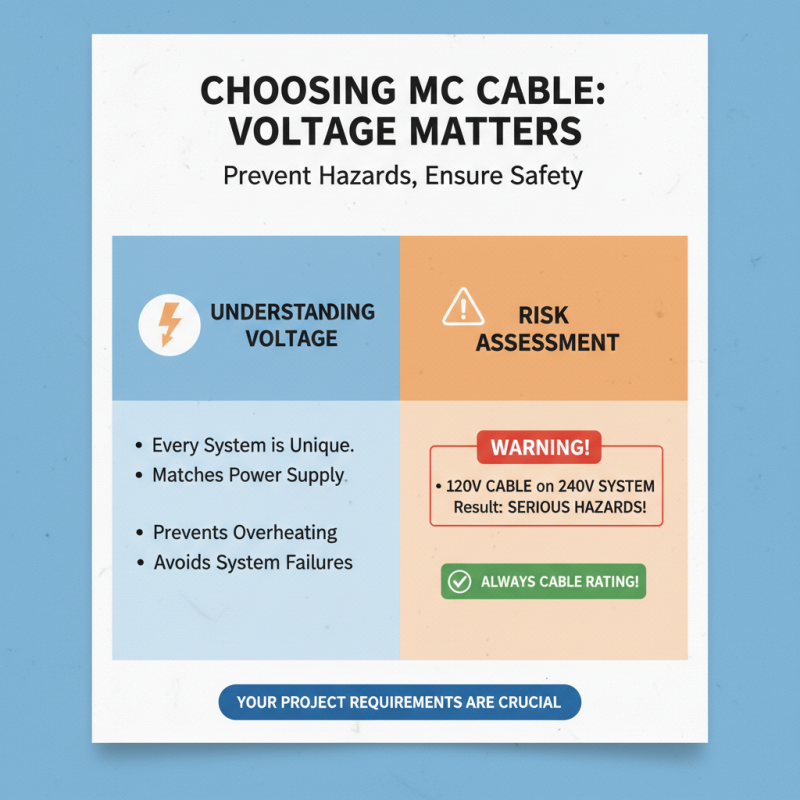

Identifying Project Requirements: Voltage, Amperage, and Environment

When choosing the right MC cable, understanding your project requirements is crucial. Start with voltage specifications. Every electrical system has a unique voltage requirement. Choosing a cable rated for the correct voltage helps prevent overheating and possible failures. For instance, using a cable meant for 120 volts in a 240-volt setup could result in serious hazards.

Next, consider the amperage. This is about how much current will flow through the cable. Each MC cable is rated for a specific amperage capacity. Exceeding this capacity, even slightly, can cause problems. It’s important to calculate your total load accurately. Some underestimate their needs, leading to insufficient wiring that might fail under heavy usage.

Lastly, think about the environment where the cable will be installed. It can be indoors, outdoors, or subject to moisture. The surroundings greatly influence your choice. In damp areas, a cable with better insulation is necessary for safety. Some environments might even require additional protection against physical damage. Always reflect on these factors to ensure you select the appropriate MC cable for your project.

Selecting the Right Size and Gauge for Your MC Cable Needs

When selecting the right size and gauge for your MC cable needs, consider your project's specific requirements. Gauge determines the wire's capacity to carry current. A thinner wire, with a higher gauge number, can't handle as much power. This can lead to overheating or potential failures. Understanding the amperage requirements is crucial.

In practice, sometimes the calculations can get tricky. You might think a 12 gauge will work, but it may not support your load. Testing different gauge sizes can help you find the optimal fit. Too often, projects face issues because the wrong gauge was chosen. Make sure to consult electrical codes as guidelines. They ensure safety and reliability in your installations.

Pay attention to cable length too. Longer runs require larger gauge cables to minimize voltage drop. You might feel tempted to cut costs, choosing a smaller gauge. This often backfires, leading to expensive corrections. Reflect on your choices thoroughly. It’s about balancing cost, safety, and performance effectively. Choosing the right MC cable size may seem straightforward, but it needs careful consideration.

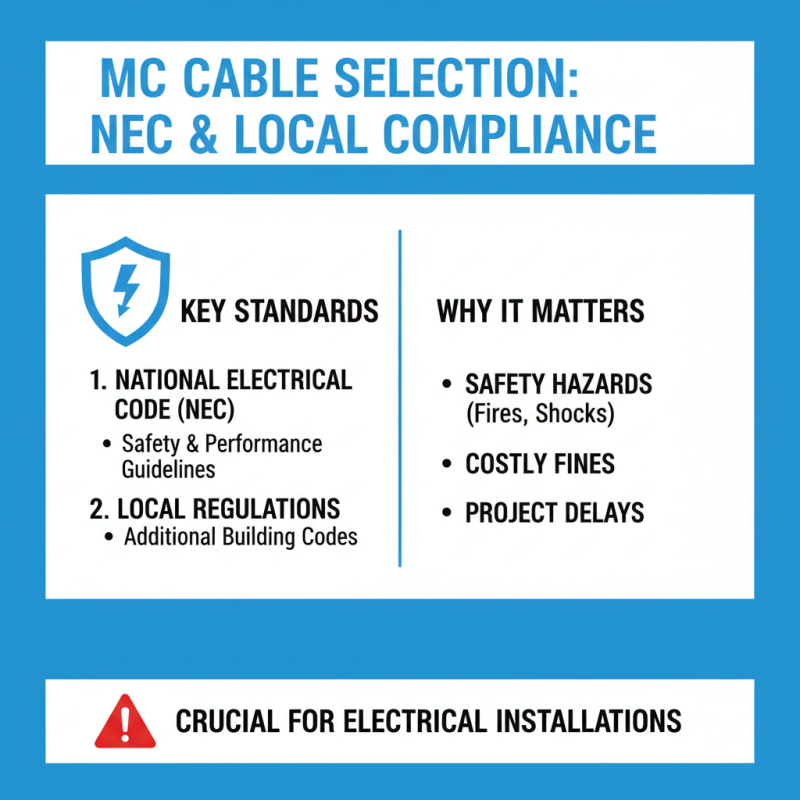

Evaluating Code Compliance: NEC Standards and Local Regulations

When selecting MC cable for your projects, compliance with the NEC standards and local regulations is crucial. These codes are designed to ensure safety and performance in electrical installations. The National Electrical Code (NEC) outlines guidelines for selecting appropriate materials and practices. Non-compliance can lead to serious safety hazards and costly fines.

One essential tip is to thoroughly review local regulations in your area. These regulations can vary significantly. Local codes may require specific types of MC cable depending on the environment, such as damp or outdoor locations. Understanding these nuances helps avoid potential pitfalls. Check local amendments to the NEC closely. Ignoring these details may result in project delays due to rework.

Another critical aspect is choosing the right insulation type. This decision can affect the long-term durability of your installation. Reports indicate that improper insulation can significantly increase risk. For example, cables used in harsh environments require tougher insulation to prevent damage. Opting for high-quality, compliant materials ensures better safety and longevity.

Lastly, always consider installation practices. Proper techniques improve compliance and enhance functionality. Incorrect installations frequently lead to electrical failures. Adhering to NEC guidelines can mitigate this risk. Understanding every detail matters in creating a safe and efficient electrical system.

Choosing Between Types: PVC vs. Aluminum vs. Copper MC Cable

When selecting MC cable, the type of material is crucial.

PVC, aluminum, and copper each serve distinct functions.

PVC is lightweight and resistant to moisture.

It is great for indoor applications but may not hold up well outdoors.

This can lead to issues over time.

Aluminum cables are a popular option.

They are lighter and more cost-effective than copper.

However, they have higher resistance and are prone to oxidation.

This oxidation can create hot spots that potentially lead to failures.

Regular inspections may be necessary to ensure safety.

Copper MC cables are known for their superior conductivity.

They can handle higher currents and do not oxidize easily.

However, they are more expensive and heavier than the other options.

This can complicate installation and increase costs.

Assessing your project’s specific needs is vital for making the right choice.

Related Posts

-

How to Select the Right MC Cable for Your Electrical Projects

-

Top 10 Benefits of Using 2 Wire Systems for Efficient Connectivity

-

10 Best Multi Conductor Cables for Superior Electrical Performance in 2023

-

2025 Top 10 Marine Cable Innovations Transforming Global Connectivity

-

What is Armoured Cable? Understanding Its Types, Benefits, and Applications

-

The Ultimate Guide to Understanding Different Wire Connector Types for Your Projects