2025 Guide to Choosing the Right Wire and Cable for Your Projects

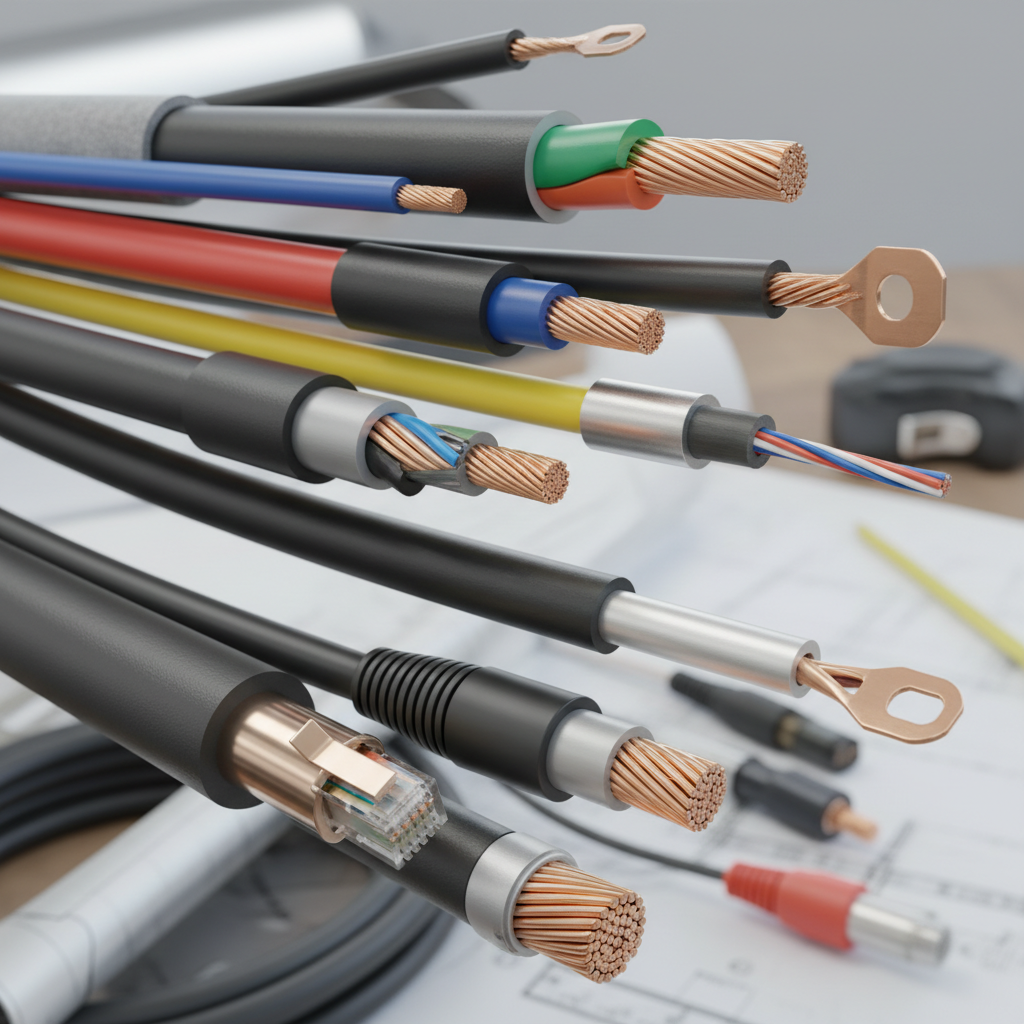

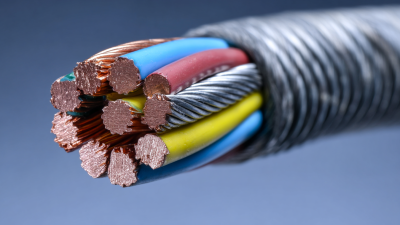

In the ever-evolving landscape of electrical engineering, the selection of the right wire and cable is crucial for ensuring operational efficiency and safety in various projects. According to a recent report by Research and Markets, the global wire and cable market is expected to reach $260 billion by 2025, driven by the increasing demand for energy-efficient solutions and technological advancements.

Industry expert Dr. John Smith, a leading authority in electrical components, emphasizes the importance of informed decision-making in this area: “Choosing the correct wire and cable not only enhances performance but also mitigates potential risks in project execution.” As we approach 2025, understanding the myriad of options available—from insulated wires for residential use to high-voltage cables for industrial applications—becomes imperative for engineers and project managers alike.

This guide will delve into the essential factors to consider when selecting wire and cable for diverse applications, offering insights that will help professionals navigate the complexities of materials and specifications. By leveraging expert advice and up-to-date industry data, stakeholders can make well-informed choices that align with current trends and future demands.

Understanding the Importance of Wire and Cable Specifications in 2025 Projects

When embarking on any electrical project in 2025, understanding wire and cable specifications is crucial for ensuring safety and efficiency. Specifications, such as voltage ratings, ampacity, and insulation types, dictate not only the performance of the electrical system but also its longevity and reliability.

For instance, selecting the right gauge can prevent overheating and potential fire hazards, while proper insulation is essential for protecting against environmental factors and electrical interference.

Moreover, compliance with industry standards and regulations is imperative in the current landscape. As technologies evolve, new materials and methods have emerged, accompanied by updated standards. Familiarizing yourself with these standards is vital, as it ensures that your chosen wiring and cabling solutions are not just appropriate for the immediate project but also future-proof. In 2025, adherence to these specifications will facilitate smoother inspections and approvals, ultimately contributing to the overall success of your project.

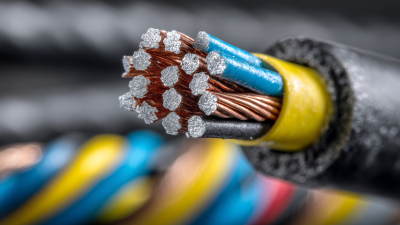

Evaluating Wire Gauge: How to Choose the Right Size for Your Electrical Needs

When selecting wire gauge for your electrical projects, it's critical to understand the relationship between wire size and electrical capacity. The American Wire Gauge (AWG) standard outlines wire sizes where a smaller gauge number indicates a thicker wire. According to the National Electrical Manufacturers Association (NEMA), a 12 AWG wire can safely carry up to 20 amps, making it suitable for residential lighting circuits. In contrast, a 14 AWG wire is only rated for up to 15 amps, which can lead to overheating if used inappropriately, emphasizing the need for careful selection based on your specific requirements.

Additionally, the voltage drop is an essential factor to consider. The National Electrical Code (NEC) recommends keeping the voltage drop under 3% for feeders and branch circuits. Using wire that is too small can cause significant energy losses, impacting performance and safety. For instance, when running a circuit over long distances, opting for a larger gauge wire, such as 10 AWG, can help maintain efficiency. Industry reports indicate that incorrect wire sizing is one of the top reasons for electrical failures, highlighting the importance of proper gauge selection in preventing potential hazards and ensuring optimal functionality in electrical systems.

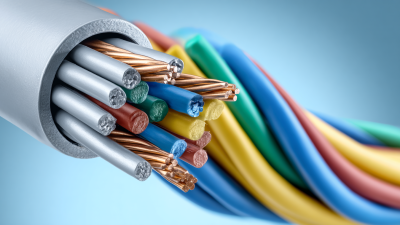

Insulation Types: Selecting the Best Material for Your Project's Environment

When choosing the right wire and cable for your projects, understanding insulation types is crucial for ensuring performance and safety in various environments. The insulation material affects not only the longevity of the cable but also its ability to withstand various environmental stressors. For instance, according to the National Electrical Manufacturers Association (NEMA), selecting the appropriate insulation can enhance a cable’s resistance to heat, moisture, and chemical exposure, which can significantly prevent premature failure.

Tip: Always consider the operating temperature range of your project. For high-temperature applications, thermoplastic materials like PVC may not suffice; instead, look for silicone or fluoropolymer-based insulations that can endure elevated temperatures without degrading.

Moreover, a recent report by the International Wire and Cable Association (IWCA) highlights that UV-resistant insulations are vital for outdoor applications, as they prevent material deterioration caused by sunlight exposure. Utilizing materials like XLPE (cross-linked polyethylene) not only offers excellent insulation properties but also enhances protection against harsh weather conditions.

Tip: Evaluate the specific environmental factors of your project site, such as exposure to chemicals or water, to choose the ideal insulation type that will maintain cable integrity over time.

Current Ratings and Temperature Factors: Ensuring Safety and Efficiency

When selecting the right wire and cable for your projects, understanding current ratings and temperature factors is crucial for ensuring both safety and efficiency. According to the National Electrical Code (NEC), wires must be rated for their intended application, and failing to adhere to these ratings can lead to overheating, short circuits, or even fire hazards. For instance, typical copper wires have a maximum ampacity rating—which depends on various factors including wire gauge and insulation type—ranging from 15 amps for 14 AWG wire to over 200 amps for larger 2/0 AWG wire in residential applications.

Temperature ratings also play a significant role in the performance of wires and cables. The American Wire Gauge (AWG) system specifies temperature ratings that define the maximum operating temperature for insulation materials. For example, THHN wire is rated for temperatures up to 90°C (194°F) in dry conditions but can drop to 60°C (140°F) in wet environments. Industry studies indicate that cable insulation deteriorates significantly when exposed to prolonged high temperatures, potentially reducing its lifespan by 50%. Therefore, selecting the appropriate wire based on current ratings and anticipated temperature exposure not only promotes safety but also optimizes the efficiency and durability of your electrical systems.

2025 Guide to Choosing the Right Wire and Cable for Your Projects

This chart illustrates the current ratings of various wire gauges, considering different temperature factors that may affect their performance. It ensures that users can make informed decisions for safe and efficient project implementations.

Cost-Effectiveness: Balancing Quality and Budget in Wire and Cable Selection

When embarking on a project that requires electrical wiring or cabling, the balance between quality and cost is paramount. High-quality materials can enhance longevity and efficiency, but cost constraints often make cheaper options tempting. To ensure cost-effectiveness, consider the specific requirements of your project—such as load capacity and environmental conditions—before making a purchase. This foresight can save you from frequent replacements or repairs down the line.

Tips: Always compare specifications on insulation ratings and conductor materials. Investing in cables with proper insulation can prevent overheating and electrical faults, offering more value over time.

Moreover, keep an eye on bulk purchasing options, as buying in larger quantities can significantly reduce costs per unit. However, avoid compromising quality for price. Look for trusted suppliers or certification marks to ensure you're selecting reliable products that will stand the test of time.

Tips: Evaluate long-term usage and potential energy savings when choosing wires. Selecting a higher quality wire might come with upfront costs, but the efficiency gains can lead to lower operational expenses.

2025 Guide to Choosing the Right Wire and Cable for Your Projects

| Wire/Cable Type | Voltage Rating (V) | Current Rating (A) | Material | Cost per Foot ($) | Applications |

|---|---|---|---|---|---|

| Stranded Copper Wire | 600 | 30 | Copper | 0.15 | Residential Electrical |

| PVC Insulated Cable | 300 | 20 | Copper | 0.10 | General Wiring |

| Aluminum Cable | 600 | 50 | Aluminum | 0.12 | Heavy-Duty Applications |

| Silicone Wire | 1000 | 15 | Copper | 0.25 | High-Temperature Applications |

| Low Voltage Cable | 48 | 15 | Copper | 0.05 | Landscape Lighting |

Related Posts

-

Exploring the Role of Cable Suppliers in Sustainable Energy Solutions

-

Top 10 Benefits of Using Soow Cable for Your Electrical Wiring Needs

-

Maximizing Safety and Efficiency: The Essential Guide to Choosing Electrical Wire Connectors in 2023

-

Understanding the Importance of Electric Cable Wire in Modern Technology

-

Understanding the Essential Role of Wire and Cable in Modern Technology Systems

-

What is Armoured Cable? Understanding Its Types, Benefits, and Applications