The Ultimate Guide to Understanding Different Wire Connector Types for Your Projects

Understanding wire connector types is essential for anyone looking to tackle electrical projects, whether you're a DIY enthusiast or a seasoned professional. With a myriad of options available, from simple butt connectors to more complex terminal blocks and splices, selecting the right connector can significantly impact the safety and functionality of your work. Each type of wire connector serves a unique purpose and is designed to suit specific applications, taking into account factors such as conductivity, durability, and environmental resistance.

In this ultimate guide, we will explore various wire connector types, detailing their features, advantages, and ideal use cases. By equipping yourself with this knowledge, you will be better prepared to make informed decisions that enhance the quality and reliability of your electrical connections, ensuring that your projects are not only efficient but also safe.

Understanding Wire Connector Types: An Overview of Common Variants

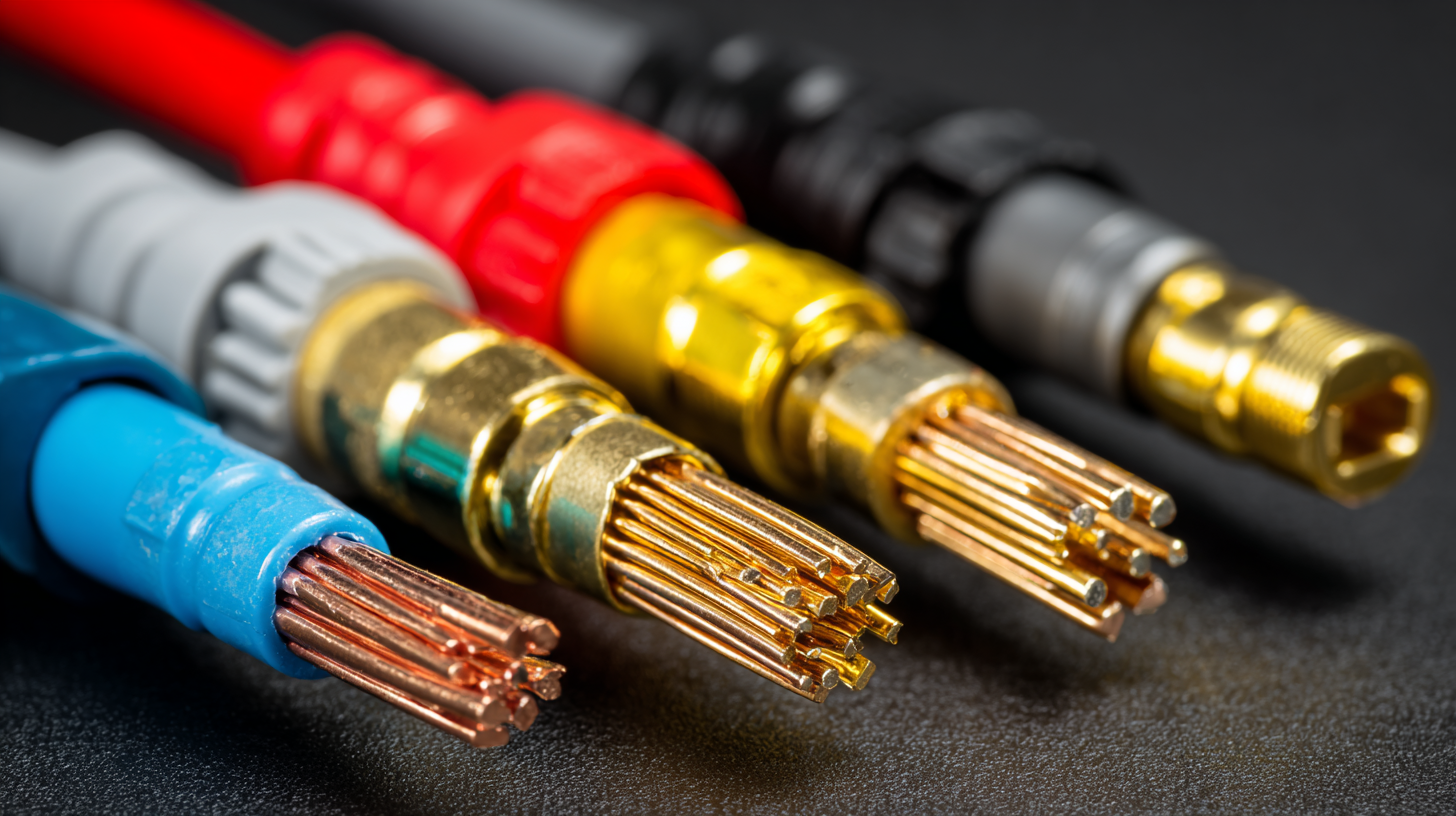

Wire connectors are essential components in electrical projects, serving the vital purpose of joining two or more electrical wires together. Understanding the various types of wire connectors can greatly enhance the quality and safety of your electrical work. Among the most common variants are twist-on wire connectors, which are easy to use and provide a secure connection by simply twisting them onto the stripped ends of wires. These connectors are particularly popular for household wiring and in applications where space is limited.

Another significant category is the crimp connectors, which require a crimping tool for proper installation. These connectors come in various forms, such as butt connectors and ring terminals, making them versatile for different applications. Crimp connectors are favored in automotive and outdoor settings where a strong bond is necessary due to environmental factors. Lastly, we have push-in connectors, which are designed for quick and tool-free connections. These are particularly beneficial in projects where speed and simplicity are paramount. By familiarizing yourself with these connector types, you can make informed choices that enhance the functionality and reliability of your electrical projects.

The Importance of Choosing the Right Wire Connector for Electrical Projects

Choosing the right wire connector is crucial for the success and safety of electrical projects. Different applications demand specific types of connectors to ensure secure and efficient connections. For instance, outdoor installations often require connectors that can withstand moisture and temperature fluctuations, while indoor projects might prioritize ease of use and aesthetics. Selecting the appropriate connector not only affects the performance of the electrical system but also impacts maintenance and troubleshooting in the future.

Choosing the right wire connector is crucial for the success and safety of electrical projects. Different applications demand specific types of connectors to ensure secure and efficient connections. For instance, outdoor installations often require connectors that can withstand moisture and temperature fluctuations, while indoor projects might prioritize ease of use and aesthetics. Selecting the appropriate connector not only affects the performance of the electrical system but also impacts maintenance and troubleshooting in the future.

In addition to functionality, the right wire connector plays a significant role in preventing electrical failures. Poorly chosen connectors can lead to increased resistance, heat buildup, and potential fire hazards. Therefore, understanding different wire connector types—such as crimp connectors, twist-on wire connectors, and soldered connections—is essential. Each type serves distinct purposes, and knowing their advantages and limitations can help in making informed decisions that enhance the reliability and longevity of electrical systems.

Detailed Comparison of Crimp, Solder, and Twist-on Wire Connectors

When embarking on any electrical project, choosing the right wire connector type is crucial. Among the most common options are crimp, solder, and twist-on connectors, each with its unique applications and advantages. According to a 2022 report by the National Electrical Manufacturers Association (NEMA), crimp connectors are favored for their reliability in high-vibration environments, making them ideal for automotive and aerospace applications. Their process involves physically deforming the connector to create a secure connection without the need for heat, which can lead to overheating issues associated with soldering.

Solder connectors, on the other hand, provide an almost permanent bond that can carry higher currents with less resistance, making them suitable for circuit board connections. However, they require careful handling, as improper technique can lead to cold solder joints and reliability issues. A 2023 study published by the International Journal of Electrical Engineering highlights that while solder connections can offer better conductivity, their susceptibility to thermal stress is a significant consideration for long-term projects.

**Tip:** When selecting a connector, consider the environmental conditions. For outdoor projects, crimp connectors with heat-shrink tubing can provide superior protection against moisture and corrosion.

Another key consideration is the ease of installation. Twist-on connectors offer a user-friendly option for those less experienced in electrical work. These connectors are quick to use and require minimal tools, making them suitable for DIY projects. Yet, it's essential to ensure they are properly twisted to avoid connection failures, as noted in a recent consumer safety report indicating that over 30% of DIY electrical failures stem from improperly installed twist-on connectors.

**Tip:** Always double-check your connections with a multimeter to ensure they meet required standards before finalizing your project.

The Ultimate Guide to Understanding Different Wire Connector Types for Your Projects

| Connector Type | Description | Advantages | Disadvantages | Common Uses |

|---|---|---|---|---|

| Crimp | A method where metal sleeves (connectors) are deformed onto wire ends using a tool. | Quick and secure connections, no soldering required, good conductivity. | Requires specific tools, potential for poor connections if not done correctly. | Automotive wiring, household electrical, and robotics. |

| Solder | Joining wires together by melting solder around the connection. | Strong, permanent connections, excellent electrical conductivity. | Time-consuming, requires skill and heat, risk of cold solder joints. | Electronics, audio equipment, and custom wiring projects. |

| Twist-on | Connections made by twisting wires together, often with a plastic cap. | Simple and easy to use, no special tools required. | Less secure than crimping or soldering, can loosen over time. | Low voltage applications, temporary connections, and repair work. |

Key Considerations for Selecting Waterproof and Heat-Resistant Connectors

When selecting wire connectors for projects that may be exposed to harsh environments, key considerations include waterproof and heat-resistant features.

Waterproof connectors are essential in scenarios where moisture exposure could lead to corrosion or short-circuiting. Look for connectors rated with an IP67 or IP68 standard, which indicates their ability to withstand dust and immersion in water.

Materials such as silicone or thermoplastics enhance the resilience of these connectors, ensuring a tight seal that prevents water ingress.

Heat resistance is equally crucial, especially for applications involving high temperatures or environments subject to heat exposure. Connectors made from materials like nylon or specific high-temperature polymers can withstand elevated temperatures without deforming or losing their electrical integrity.

Additionally, examining the temperature ratings specified by the manufacturer helps ensure that the connectors will perform reliably under expected conditions. Combining these considerations will not only extend the lifespan of the electrical connections but also enhance the overall safety and reliability of your projects.

Industry Standards: Gauge Ranges and Current Ratings for Wire Connectors

When selecting wire connectors for your projects, understanding the gauge ranges and current ratings is essential. Wire gauge refers to the diameter of the wire, which directly affects its current-carrying capacity. Generally, the lower the gauge number, the thicker the wire and the higher the current it can handle. For example, a 10-gauge wire can handle significantly more current than a 20-gauge wire, making it crucial to choose the right gauge for your specific application.

Tips: Always refer to the National Electrical Code (NEC) guidelines when determining wire gauge requirements. This will ensure that your project adheres to safety standards and helps prevent overheating or potential fires. Additionally, consider using connectors that are rated for higher currents than what you plan to use, giving you extra safety margin and flexibility for future modifications.

Another vital factor is the current rating of the connectors themselves, which indicates the maximum current they can handle safely. When combining different wire gauges and connectors, ensure that both are compatible in terms of current rating to maintain system integrity. Checking manufacturer specifications can help you avoid mismatches that could lead to electrical failures.

Tips: Invest in high-quality connectors that meet industry standards to ensure reliability and longevity in your projects. Using connectors with appropriate insulation ratings for the intended environment—whether exposed to moisture, heat, or chemicals—can further enhance safety and performance.