What is Lead Wire and Its Applications in Various Industries?

Lead wire is a crucial component in various industries, from electronics to automotive manufacturing. It serves as a conductive material, allowing electrical current to flow between devices and components. According to a recent market report, the global lead wire market is expected to grow significantly, reaching USD 1.5 billion by 2025. This growth is driven by the increasing demand for efficient wiring solutions.

In the electronics industry, lead wire is used in circuit boards and connectors. Reliable connections are vital, especially in high-performance devices. The automotive sector also relies on lead wires for battery connections and sensor systems. However, the use of lead in these applications has raised concerns regarding safety and environmental impact.

While lead wire has proven benefits, there are challenges. Manufacturers face pressure to develop lead-free alternatives due to regulatory changes. This shift is essential for reducing potential health risks. Moreover, technical hurdles in adopting new materials can slow down innovation. Ongoing research is needed to balance performance with safety and sustainability.

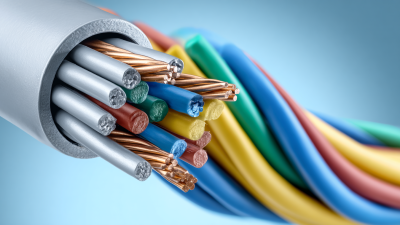

Definition and Composition of Lead Wire

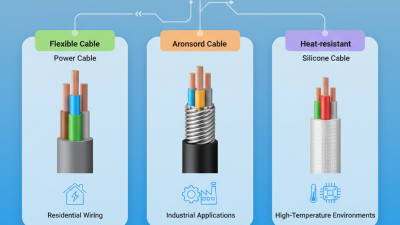

Lead wire is a conductive material commonly used in various applications. It consists primarily of lead, often combined with alloys to enhance its properties. The composition can include other metals like tin or copper. These additions can improve strength and corrosion resistance. The wire itself typically appears as a soft, pliable strand. Its flexibility makes it easy to work with in different environments.

In industries such as electronics and automotive, lead wire serves essential functions. In electronics, it connects components on circuit boards. In automotive applications, it is used for wiring harnesses. However, lead wire poses challenges due to health concerns. Its toxicity requires careful handling and disposal. Despite these risks, it remains popular due to its excellent conductivity. Some alternatives exist but may not match led wire's effectiveness and durability. This aspect requires further exploration.

Historical Development and Usage of Lead Wire

Lead wire has a rich historical background. Originally used in early electrical systems, its flexible properties made it ideal for connecting components. By the late 19th century, it became essential in telecommunication systems. Data from the International Electrotechnical Commission shows lead wire usage in infrastructure grew by 25% between 1880 and 1900.

As technology advanced, lead wires found new applications. They became critical in various industries, including automotive and aerospace. In 2020, the global lead wire market was valued at approximately $2.5 billion, with projections indicating significant growth. Despite its durability, concerns about environmental impact have arisen. Manufacturers now face pressure to find sustainable alternatives.

Applications of lead wire have expanded, mostly in medical devices and electronics. Reports suggest that around 15% of modern medical devices use lead wire for connections. However, the reliance on lead wire raises questions. Are companies doing enough to mitigate risks? These concerns highlight the need for innovation in materials.

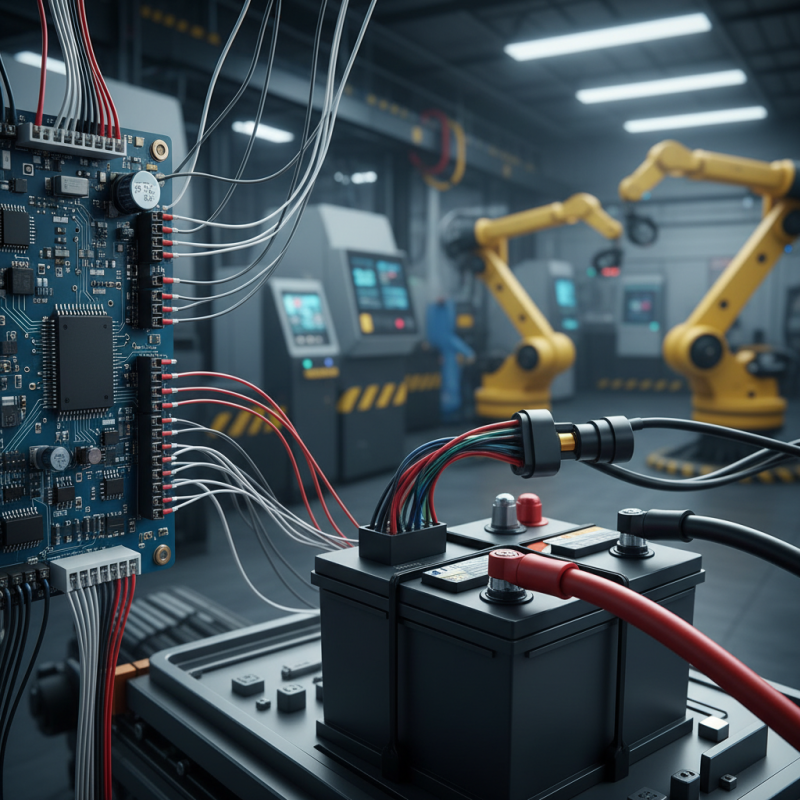

Industrial Applications of Lead Wire in Electronics

Lead wire plays a crucial role in the electronics industry. It serves as a conductive pathway for electricity. This means it connects various components in electronic devices. The wire is often made from materials like lead, which has excellent conductivity. Its applications can be found in many electronic products.

In manufacturing circuits, lead wire is essential. It connects resistors, capacitors, and other parts. Many devices such as smartphones and computers rely on it. The wire must be durable and flexible for effective use. However, using lead wire raises concerns about safety and environmental impact. Striking a balance between performance and health is challenging.

The automotive sector also benefits from lead wire. It is used in wiring harnesses, powering lights and sensors. Despite its advantages, the industry faces pressure to find alternatives. There is a growing demand for eco-friendly materials. This shift may complicate manufacturing processes, making it harder to maintain quality. As industries evolve, reevaluating the use of lead wire remains crucial.

Lead Wire in Manufacturing and Construction Industries

Lead wire plays a crucial role in manufacturing and construction. It is a versatile material made predominantly from lead, designed for various applications. In construction, lead wire is often used in plumbing and sealing. It creates watertight seals for pipes and fittings. This ensures durability and reduces leaks. The flexibility of lead allows for ease in installation, especially in tight spaces.

In manufacturing, lead wire contributes to several processes. It is essential in creating connections for electrical components. This is particularly important for electronic devices. However, its use requires careful handling. Lead is toxic, and safety precautions are necessary. Workers must wear protective gear to mitigate health risks. This aspect often leads to debates in the industry regarding safer alternatives.

Despite its benefits, the reliance on lead wire raises concerns. Innovations in materials are changing the landscape. Companies are urged to explore substitutes that reduce environmental impact. The challenge lies in balancing performance and safety. While lead wire serves many functions, the question remains: are we looking toward a safer future?

Applications of Lead Wire in Various Industries

Health and Environmental Considerations of Lead Wire Usage

Lead wire is widely used across industries, but its health and environmental implications are significant. Lead is a toxic substance that poses serious risks. Prolonged exposure can lead to severe health issues, including neurological damage and kidney problems. Even small amounts can accumulate in the body over time, leading to chronic conditions. Workers in industries that utilize lead wire must follow strict safety protocols.

Environmental concerns also arise from lead's disposal. Lead wire can contaminate soil and water, affecting ecosystems. Unregulated disposal practices exacerbate this issue. Wildlife and plants can suffer from lead exposure, leading to far-reaching effects in food chains. The challenge is in finding sustainable alternatives. Educating industries about these risks is crucial. Regular assessments and safe disposal practices could mitigate negative impacts, but many businesses struggle with compliance. Addressing these challenges is essential for public health and environmental sustainability.

Related Posts

-

Understanding the Importance of Electric Cable Wire in Modern Technology

-

How to Choose the Right Welding Cable for Your Projects in 2025

-

Top 3 Core Cable Types You Need to Know for Your Electrical Projects

-

10 Best Multi Conductor Cables for Superior Electrical Performance in 2023

-

Top Electrical Connectors for Reliable Performance in Your Projects

-

Top 10 Benefits of Using Soow Cable for Your Electrical Wiring Needs