Maximizing Safety and Efficiency: The Essential Guide to Choosing Electrical Wire Connectors in 2023

In the ever-evolving landscape of electrical installations, the importance of selecting the right electrical wire connectors cannot be overstated. According to recent industry reports, improper connector choices contribute to nearly 20% of electrical failures, leading to both safety hazards and costly downtimes. As the demand for reliable and efficient electrical systems continues to rise, so does the necessity to adopt best practices in selecting connectors that ensure both safety and performance.

As of 2023, advancements in technology and materials have further highlighted the critical role of electrical wire connectors in various applications, from residential wiring to industrial setups. The global electrical connector market is projected to reach $94.1 billion by 2025, underscoring the increasing recognition of the integral part these components play in modern electrical systems. Choosing the appropriate electrical wire connector not only enhances safety but also significantly improves the overall functionality and longevity of electrical systems.

In this essential guide, we will explore key considerations and expert insights tailored to aid both professionals and DIY enthusiasts in making informed decisions about electrical wire connectors. We will examine critical factors such as compatibility, load requirements, and environmental conditions, ensuring you have the knowledge to maximize safety and efficiency in your electrical projects.

Understanding the Importance of Electrical Wire Connectors for Safety and Efficiency

Electrical wire connectors play a crucial role in ensuring both safety and efficiency in various applications. These connectors are essential for maintaining secure electrical connections, which helps prevent hazards such as electric shocks and short circuits. Understanding the importance of these connectors is vital, particularly in environments with high risks, like hot tubs and industrial settings. Regular inspections and maintenance of electrical systems can mitigate potential dangers, ensuring that connections remain intact and functional.

Moreover, the current landscape reveals the increasing significance of reliable electrical connections, especially as the market for electrical infrastructure grows. For instance, with the global railway wiring harness market projected to expand significantly, the demand for quality electrical wire connectors will also rise. Accurate current balancing in power systems is critical; a failure to do so can lead to equipment damage and safety concerns. Therefore, comprehensively understanding and selecting the right electrical wire connectors is essential for optimizing safety and efficiency in various applications.

Maximizing Safety and Efficiency: The Essential Guide to Choosing Electrical Wire Connectors in 2023

| Connector Type | Current Rating (Amps) | Wire Gauge Compatibility | Temperature Rating (°C) | Materials | Applications |

|---|---|---|---|---|---|

| Butt Connector | 30 | 22-16 AWG | 105 | Copper | General Wiring |

| Ring Terminal | 50 | 14-10 AWG | 90 | Copper with Tin Plating | Automotive, Marine |

| Heat Shrink Connector | 40 | 22-12 AWG | 125 | Polyolefin | Waterproof Applications |

| Splice Connector | 25 | 18-16 AWG | 80 | Aluminum | Electrical Distribution |

| Junction Connector | 60 | 14-10 AWG | 110 | Copper | Residential Wiring |

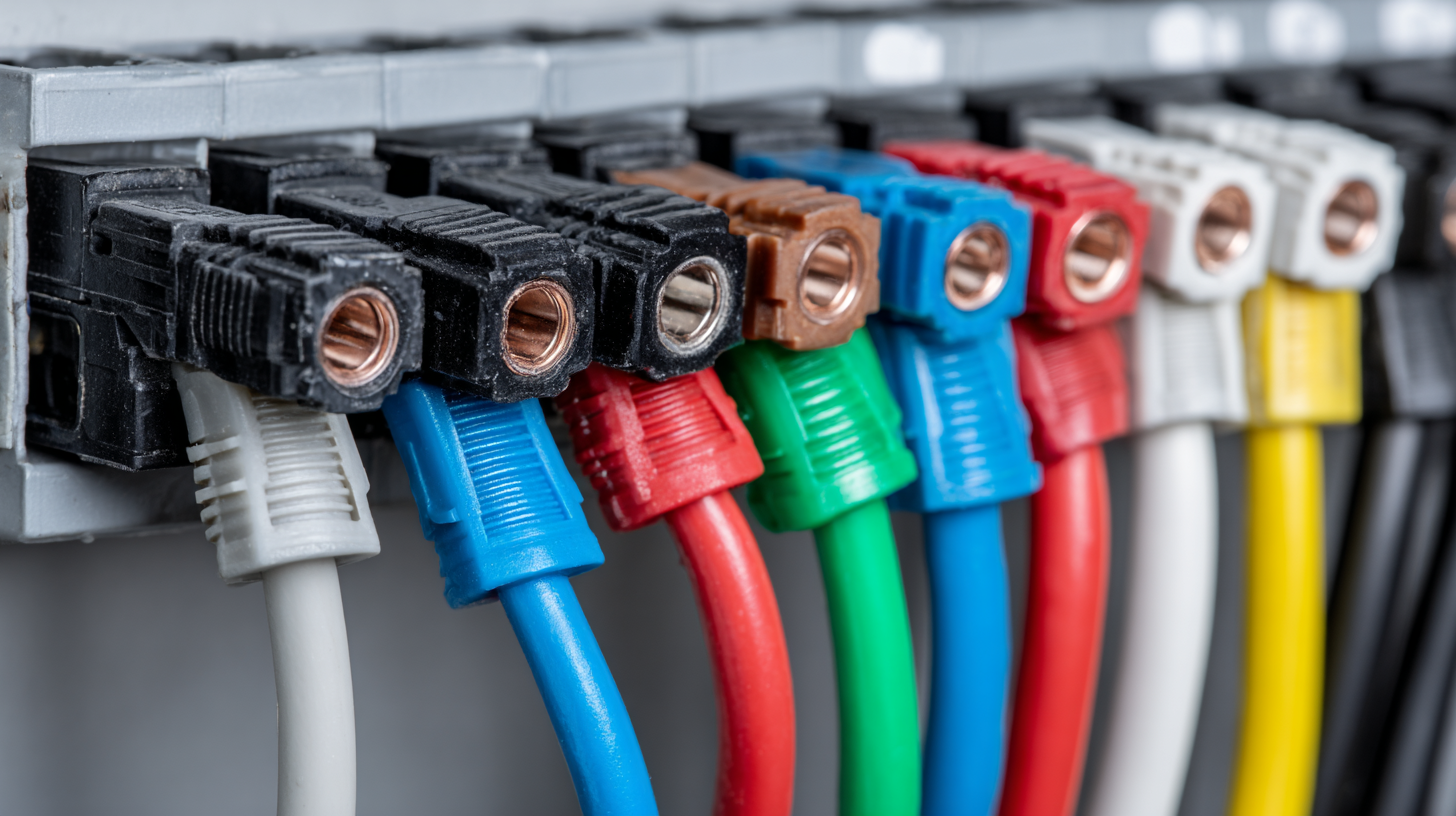

Types of Electrical Wire Connectors: Choosing the Right Type for Your Project

When selecting electrical wire connectors, it's essential to understand the various types available to ensure both safety and efficiency in your projects. According to a recent report by the National Electrical Contractors Association (NECA), the use of appropriate connectors can reduce electrical failures by as much as 30%. This emphasizes the importance of choosing the right connector type, which can vary based on wire material, application, and environmental factors.

There are several common types of electrical wire connectors, including crimp connectors, screw-on connectors, and push-in connectors. Crimp connectors, for instance, are often favored for their reliability and secure connections, particularly in high-vibration environments. A study from the Electrical Safety Foundation International (ESFI) found that crimp connectors outperform others in maintaining connection integrity under strain, making them ideal for automotive and heavy-duty applications. On the other hand, screw-on connectors are versatile and easy to use, making them suitable for DIY projects. Ultimately, understanding these connector types and their specific benefits allows for informed decision-making, ensuring that projects are completed safely and efficiently.

Key Features to Look for in Electrical Wire Connectors: A Comprehensive Overview

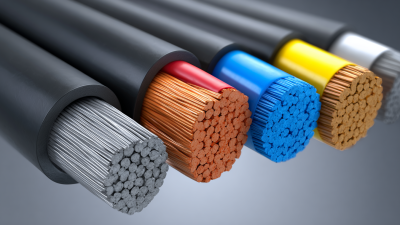

When selecting electrical wire connectors, it's crucial to consider several key features that ensure safety and efficiency. First, the material of the connector plays a significant role in its performance. Look for connectors made from high-quality materials such as copper or brass, which offer excellent conductivity and resistance to corrosion. Additionally, connectors with insulating properties, like nylon or polycarbonate, contribute significantly to reducing the risk of electrical shorts and enhancing durability.

Another important aspect is the connector's design. Opt for connectors that feature a secure locking mechanism, which minimizes the risk of accidental disconnection. Furthermore, examine the compatibility of connectors with the wires you intend to use; ensure they can handle the appropriate gauge and voltage requirements. Lastly, consider the environmental ratings of the connectors, especially if they will be exposed to moisture or extreme temperature fluctuations.

Selecting connectors that meet these critical specifications will not only maximize safety but also enhance the overall efficiency of your electrical projects.

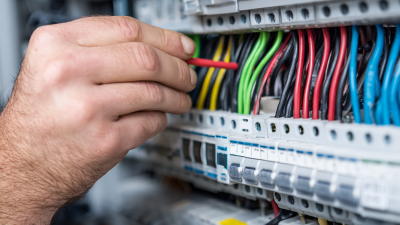

Best Practices for Installing Electrical Wire Connectors to Maximize Performance

When it comes to maximizing the performance of electrical wire connectors, installation practices play a crucial role. Ensuring a clean, secure connection can prevent potential hazards and enhance efficiency. One key tip is to always strip the wire insulation carefully to avoid damaging the conductor. Use a wire stripper tool specifically designed for the gauge of wire you are working with. This ensures that your connections are secure and minimizes the risk of short circuits.

Another essential practice is to choose the right type of connector for your application. Different environments and wire sizes require specific connectors, such as crimp, solder, or twist-on types. It's important to use connectors that are rated for the voltage and current specifications of your project. Additionally, always check for compatibility with the wire insulation type, as mismatched materials can lead to overheating and failure.

Lastly, maintaining proper torque and torque specifications when securing connectors is crucial for long-term performance. Over-tightening can damage connectors or wires, while under-tightening may lead to loose connections. Make use of a torque wrench to ensure you're applying the correct amount of pressure, keeping your connections safe and efficient throughout their lifespan.

Maximizing Safety and Efficiency: Electrical Wire Connectors Performance in 2023

Common Mistakes to Avoid When Selecting Electrical Wire Connectors for Your Applications

When selecting electrical wire connectors, one of the most common mistakes is underestimating the importance of compatibility. Not all connectors are suited for every type of wire or application. Using connectors that are mismatched with the wire gauge or insulation can lead to increased resistance, overheating, and potential failure of the electrical connection. It's critical to thoroughly check specifications and choose connectors that are designed for your specific wire type to ensure optimal performance.

Another common oversight is overlooking the environment in which the connectors will be used. Factors such as temperature, humidity, and exposure to chemicals can significantly impact connector performance and longevity. For instance, connectors that work well in indoor settings may not withstand the rigors of outdoor environments or extreme conditions. Always consider the operational environment and select connectors that offer the right protective features, such as weather resistance or insulation materials, to avoid premature degradation and ensure safe, reliable connections.

Related Posts

-

The Ultimate Guide to Understanding Different Wire Connector Types for Your Projects

-

Exploring the Advantages of 4 Core Cable in Modern Electrical Installations and Its Impact on Efficiency

-

Understanding the Benefits and Uses of Romex Wire in Modern Electrical Installations

-

Exploring the Essential Role of Power Wires in Modern Electrical Systems

-

Understanding Lead Cables: Essential Insights for Safe Electrical Installations

-

Understanding Multi Conductor Cables: Essential Tips for Effective Electrical Wiring