Why is Power Wire Essential for Electrical Safety and Efficiency?

In the realm of electrical systems, power wire stands as a critical component for ensuring both safety and efficiency. According to a report by the National Fire Protection Association (NFPA), faulty wiring accounts for over 30% of electrical fires. This staggering statistic highlights the importance of using high-quality power wire in residential and industrial applications.

Expert electrical engineer Dr. David Green expresses, "The right power wire not only enhances efficiency but also significantly reduces risks associated with electrical hazards." The selection of appropriate power wire can directly influence the performance of electrical systems. Yet, many overlook this crucial aspect, leading to inefficient operations and potential dangers.

Choosing the wrong specifications in power wire can result in heat buildup and equipment failure. These overlooked details often require costly repairs or replacements. Thus, a proper understanding of power wire is vital for every project. Awareness and education about power wire are needed to mitigate risks. Investing in quality power wire can save lives and resources in the long run.

Importance of Power Wire in Electrical Systems

Power wires are critical components in electrical systems. They carry electrical current safely from one point to another. High-quality power wire ensures efficient energy transfer, reducing wasted energy. According to the National Electrical Code, proper wiring can prevent overheating and electrical fires. Inadequate or damaged wires might lead to severe hazards.

The efficiency of electrical systems hinges on the integrity of power wires. A study by the International Electrotechnical Commission highlights that up to 30% of energy loss in electrical systems can be attributed to poor wiring. Faulty connections or lower gauge wires increase resistance. This not only affects performance but also raises electricity costs. Often, overlooked maintenance of power wires can introduce new risks.

It's important to recognize that not all installations meet safety standards. Reports show that improper wiring is responsible for a significant number of electrical accidents. Routine checks and updates are crucial for mitigating such risks. Awareness and proactive measures can lead to safer environments and improved energy efficiency.

Why is Power Wire Essential for Electrical Safety and Efficiency?

| Dimension | Description | Importance |

|---|---|---|

| Conductor Material | Copper and aluminum are commonly used conductors. | Conductivity affects efficiency and heat generation. |

| Wire Gauge | Refers to the thickness of the wire, measured in AWG. | Influences current capacity and voltage drop. |

| Insulation Type | Materials like PVC, XLPE, and rubber are used for insulation. | Prevent shorts and improve safety under various conditions. |

| Heat Resistance | Refers to the wire's ability to operate under high temperatures. | Prevents wire damage and fire hazards in high-load scenarios. |

| Flexibility | The ability of the wire to bend without breaking. | Facilitates installation in tight spaces and reduces the risk of damage. |

| Current Rating | The maximum current the wire can safely carry. | Ensures safe operation without overheating or failure. |

Understanding Electrical Safety Standards for Power Wires

Power wires play a crucial role in maintaining electrical safety. They must comply with various electrical safety standards. These standards ensure that wires can handle the expected voltage and current. Proper insulation is vital, preventing accidental shocks. Unsafe wiring can lead to severe hazards, including fire.

Understanding these standards is essential for consumers and electricians alike. It helps in selecting the right wires for specific applications. For example, using a wire with insufficient insulation in wet areas can create dangerous conditions. Attention to detail is critical in this field. Over time, even high-quality wires may degrade. Inspections and regular maintenance can help.

Not all installations meet the necessary safety standards. Sometimes, budget constraints lead to shortcuts. This can create risky situations, especially in residential settings. Awareness and education about these guidelines can help prevent accidents. It’s important to recognize that while power wires are often overlooked, they are integral to our safety. Investing time in understanding their role is essential.

Components of Power Wire and Their Role in Efficiency

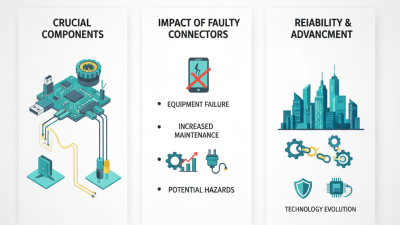

Power wire plays a crucial role in electrical systems. Its components, such as conductors, insulators, and connectors, greatly affect efficiency.

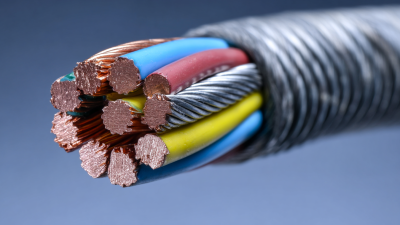

Conductors, often made of copper or aluminum, carry electrical current. Their gauge size influences the flow of energy. Thicker wires can reduce resistance, but they are heavier and less flexible.

Insulators, usually made of rubber or plastic, prevent accidental contact. They protect users and ensure current flows as intended. Poor quality insulators may lead to safety hazards. Connectors link different wires and components. Their design affects both stability and function. Misconnections can cause inefficiency or even system failures.

There are challenges in selecting the right power wire. Users often overlook the importance of compatibility between different wire types. This can lead to overheating or energy loss. Regular maintenance is essential for monitoring wear and tear. Not addressing these issues quickly can result in costly repairs. Understanding these components and their roles can enhance safety and efficiency in electrical use.

Common Risks Associated with Poor Quality Power Wires

Poor quality power wires can pose severe risks. According to a report by the National Fire Protection Association, faulty wiring accounts for about 6% of all residential fires. This figure highlights the importance of using reliable materials. Inferior wires may lead to overheating, which can spark dangerous fires. Additionally, they often lack the necessary insulation, making them vulnerable to electrical faults.

Another issue is electrical shock. Low-quality wires may fray or break more easily, exposing live wires. A study from the Institute of Electrical and Electronics Engineers found that around 30% of electrical shock incidents are linked to defective wiring. Such wires compromise safety standards, endangering lives and properties. Effective monitoring of wire quality can significantly reduce these risks.

Cost-cutting measures can lead to serious consequences. Some installers may opt for cheaper materials to save money. This short-term thinking can lead to long-term issues. The Electric Safety Foundation International suggests investing in quality wiring can prevent fatal accidents. Making wise choices with power wires is crucial for safety and efficiency.

Impact of Power Wire Quality on Electrical Safety and Efficiency

Best Practices for Selecting and Maintaining Power Wires

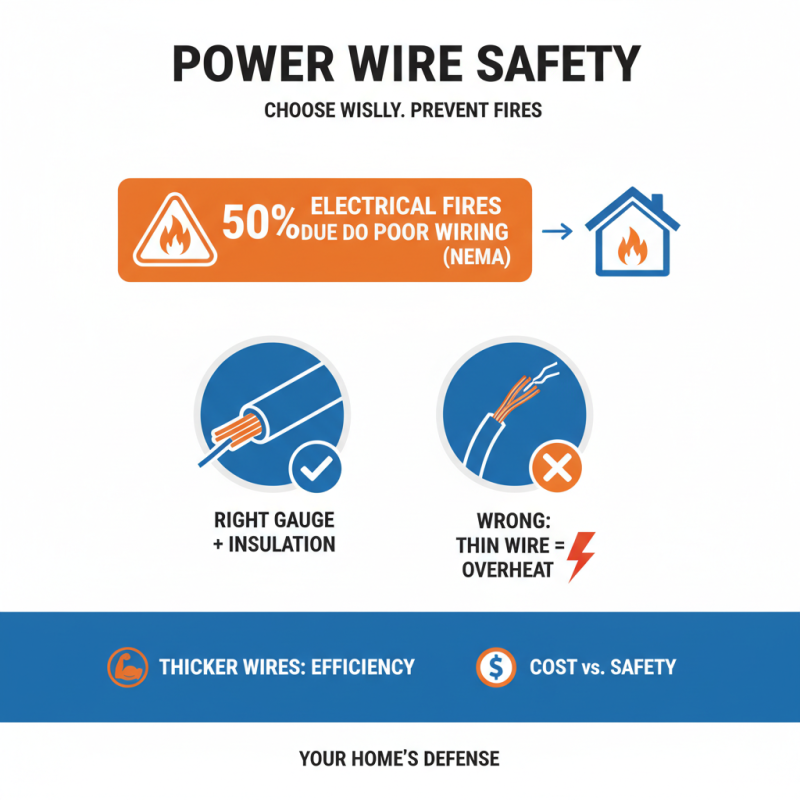

Choosing the right power wire is critical for safety. According to the National Electrical Manufacturers Association (NEMA), nearly 50% of electrical fires result from poor wiring practices. Selecting wires with suitable insulation and gauge is essential. A wire that is too thin may overheat and fail, creating a serious hazard. Using thicker wires can improve efficiency but may increase costs.

Maintaining power wires is equally important. Regular inspections can identify wear and tear. NEMA reports that 30% of electrical issues can be traced back to damaged wires. Signs of damage include fraying, discoloration, and exposed copper. It’s crucial to address these issues promptly. Neglecting maintenance not only poses safety risks but can also lead to increased energy consumption.

Selecting wires that meet established safety standards is vital. Look for wires rated for the specific application. Remember, cheap materials often compromise safety. Wires should also be compatible with the electrical load. Using improper wire types can create unexpected failures. Regular training on wire selection and maintenance can prevent costly mistakes.

Related Posts

-

How to Choose the Right Power Wire for Your Electrical Projects?

-

The Ultimate Guide to Understanding Different Wire Connector Types for Your Projects

-

How to Choose the Right Wire Cable for Your Project?

-

Why Are Electrical Connectors Essential for Reliable Electrical Connections?

-

How to Choose the Right Welding Cable for Your Project?

-

What is Armoured Cable? Understanding Its Types, Benefits, and Applications