Top 10 Uses of Thermocouple Wire in Industrial Applications

In the dynamic landscape of industrial applications, thermocouple wire has emerged as a vital component for temperature measurement and control. As industries increasingly prioritize precision in their processes, the demand for reliable thermocouple wire continues to rise. According to a recent report by MarketsandMarkets, the global thermocouple market is projected to reach USD 2.5 billion by 2025, growing at a CAGR of 5.4%. This underscores the critical role that thermocouple wire plays in sectors such as manufacturing, energy, and aerospace, where accurate temperature monitoring is essential for operational efficiency and safety.

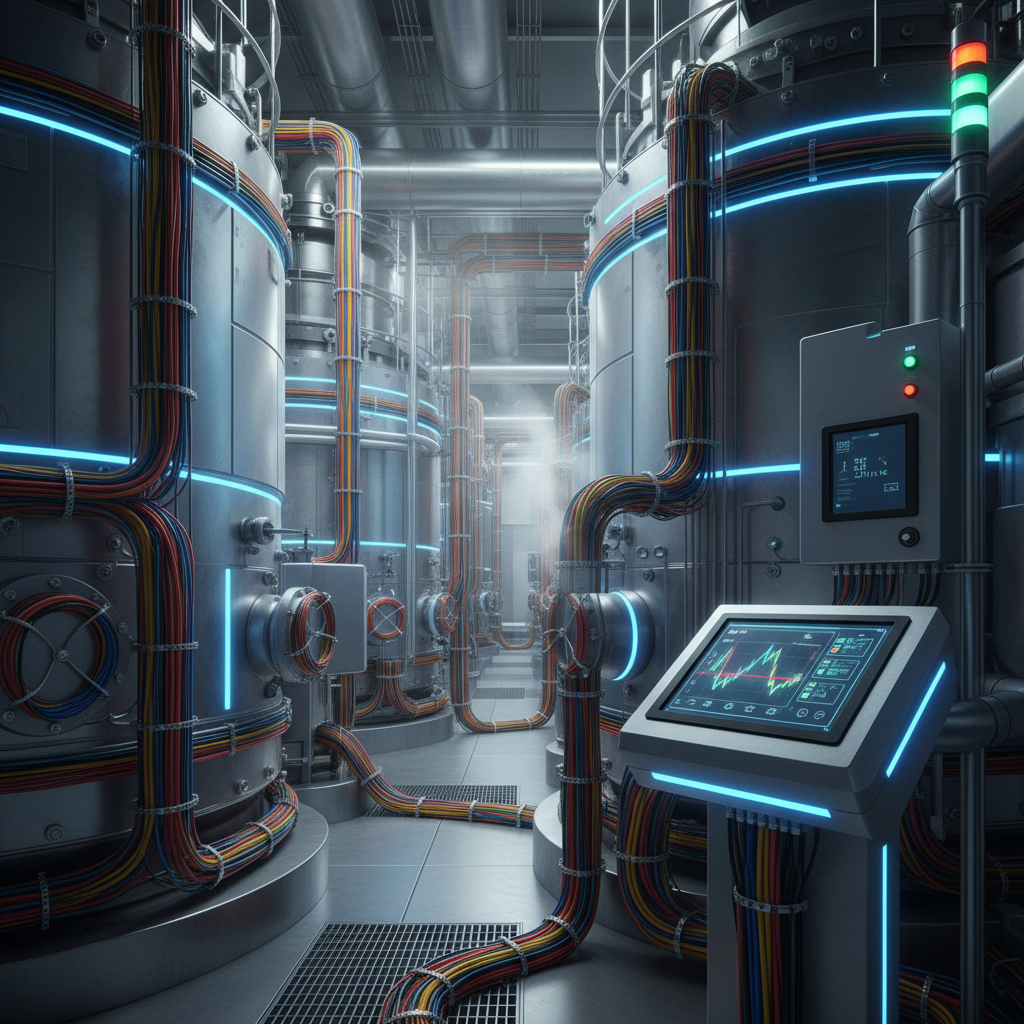

The versatility of thermocouple wire is evident in its wide range of applications—from monitoring furnace temperatures to ensuring optimal operating conditions in power plants. As technology advances, newer thermocouple wire materials are being developed, enhancing their performance in extreme conditions. Additionally, the integration of thermocouple wire into smart industrial systems supports the ongoing trend toward automation and improved data analytics. With a focus on both traditional and innovative uses, this article will explore the top ten applications of thermocouple wire in the industrial landscape, highlighting its significance in maintaining productivity and ensuring compliance with modern industry standards.

Applications of Thermocouple Wire in Temperature Measurement Across Industries

Thermocouple wires are integral to temperature measurement in various industrial applications, including manufacturing, aerospace, and energy sectors. According to a report by MarketsandMarkets, the global thermocouple market is projected to reach over $420 million by 2025, driven by the increasing demand for temperature control processes. In manufacturing, thermocouples are commonly used for monitoring critical temperature points to ensure product quality and compliance. For instance, in metal processing, thermocouple wires help maintain precise temperature levels during melting, forging, and heat treatment processes, ultimately improving efficiency and product integrity.

In the energy sector, thermocouple wires play a vital role in power generation and energy management. They are employed in monitoring the temperature of turbines, boilers, and reactors, where even slight variations can impact safety and efficiency. A report from Allied Market Research highlights that the utility sector alone is expected to account for a significant share of the thermocouple market due to growing investments in thermal power generation. With advancements in technology, the accuracy and durability of thermocouple wires continue to enhance, making them an indispensable tool in temperature measurement across industries.

Top 10 Uses of Thermocouple Wire in Industrial Applications

Innovative Uses of Thermocouple Wire in Process Control and Automation

In the realm of process control and automation, thermocouple wire plays an integral role, providing critical temperature measurement essential for maintaining optimal operational conditions. Recent industry advancements highlight how precision instruments, like advanced single loop controllers, leverage thermocouple technology to enhance system reliability and responsiveness. With a focus on reducing the workload on personnel throughout installation and maintenance phases, these innovations are vital in streamlining factory automation processes.

Additionally, modern data acquisition systems now incorporate thermocouples alongside traditional sensors, enabling seamless integration with legacy systems. This versatility supports a wide range of industrial applications, from small-scale operations to complex automated environments. Reports indicate that the integration of thermocouples into industrial automation frameworks can lead to significant improvements in setup times and overall system efficiency. As industries continue to prioritize precision and automation, the demand for high-quality thermocouple wire is expected to amplify, driving further innovations and applications across sectors.

The Role of Thermocouple Wire in Quality Assurance and Safety Monitoring

Thermocouple wire plays a crucial role in quality assurance and safety monitoring across various industrial applications. By accurately measuring temperature, thermocouples ensure that processes such as manufacturing and food production operate within strict temperature thresholds. This precision is vital for maintaining product quality, as deviations can lead to defects or spoilage. For instance, in the food industry, thermocouple wires help monitor cooking temperatures, ensuring that the final products are safe for consumption. This adherence to temperature standards not only enhances product quality but also helps in meeting regulatory compliance.

In addition to quality control, thermocouple wire is essential for safety monitoring in environments where excessive heat can pose serious hazards. Industries such as oil and gas, chemical manufacturing, and power generation rely on thermocouple systems to detect overheating in critical equipment. Implementing these temperature sensors can prevent catastrophic failures, minimize downtime, and protect workers from potential dangers associated with thermal events. Their ability to provide real-time data ensures that any temperature anomalies are addressed promptly, thus reinforcing the overall safety culture within industrial operations.

Utilization of Thermocouple Wire in Research and Development Settings

In research and development settings, thermocouple wire plays a crucial role, especially when advanced materials are tested under extreme conditions. A recent study on high-temperature irradiation-resistant thermocouples (HTIR-TCs) highlights the development of an instability model tailored for in-pile reactor applications. This innovation is vital as it addresses operational challenges faced in environments where radiation and high temperatures can compromise measurement integrity. The stability and accuracy of temperature readings are paramount in ensuring safety and efficiency in reactor operations, where even minor inaccuracies can lead to significant operational risks.

According to industry reports, the global market for thermocouples is projected to reach $2.97 billion by 2025, growing at a CAGR of 5.6%. This growth is driven by the increasing demand for reliable temperature measurement in both R&D and industrial applications. In particular, the advancement of materials capable of withstanding hostile environments has created new opportunities for thermocouples, making them indispensable tools in experimental setups. As researchers strive for greater accuracy and dependability, the role of thermocouple wire will undoubtedly expand, especially in high-stakes fields such as nuclear energy and advanced manufacturing processes.

Future Trends and Advancements in Thermocouple Wire Applications for 2025

As we look towards 2025, the applications of thermocouple wire in industrial settings are expected to undergo significant advancements. With the increasing emphasis on energy efficiency and sustainability, thermocouples will play a vital role in optimizing thermal management systems. Emerging trends in thermal energy storage technologies indicate that the use of thermocouple wire will expand, providing precise temperature measurements necessary for enhancing the performance of various thermal energy storage mechanisms. This will not only improve system reliability but also boost operational efficiency across different sectors such as manufacturing and renewable energy.

Moreover, advancements in artificial intelligence and data analytics will further enhance the functionality of thermocouple wire applications. Integrating smart technology with thermocouple systems can lead to real-time monitoring and predictive maintenance, allowing industries to respond proactively to temperature fluctuations. As the demand for high-accuracy temperature sensing continues to grow, particularly in sectors like healthcare and precision manufacturing, the evolution of thermocouple wire will be crucial in supporting innovative solutions that address the increasing complexity and requirements of modern industrial processes.

Related Posts

-

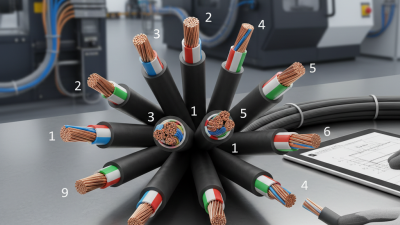

Top 10 Control Cable Types for Optimal Performance in Industrial Applications

-

Understanding Lead Cables: Essential Insights for Safe Electrical Installations

-

Understanding the Benefits and Uses of Romex Wire in Modern Electrical Installations

-

What is Armoured Cable? Understanding Its Types, Benefits, and Applications

-

Understanding the Essential Role of Wire and Cable in Modern Technology Systems

-

Exploring the Advantages of 4 Core Cable in Modern Electrical Installations and Its Impact on Efficiency