Essential Tips for Choosing a Reliable Chemical Raw Materials Manufacturer?

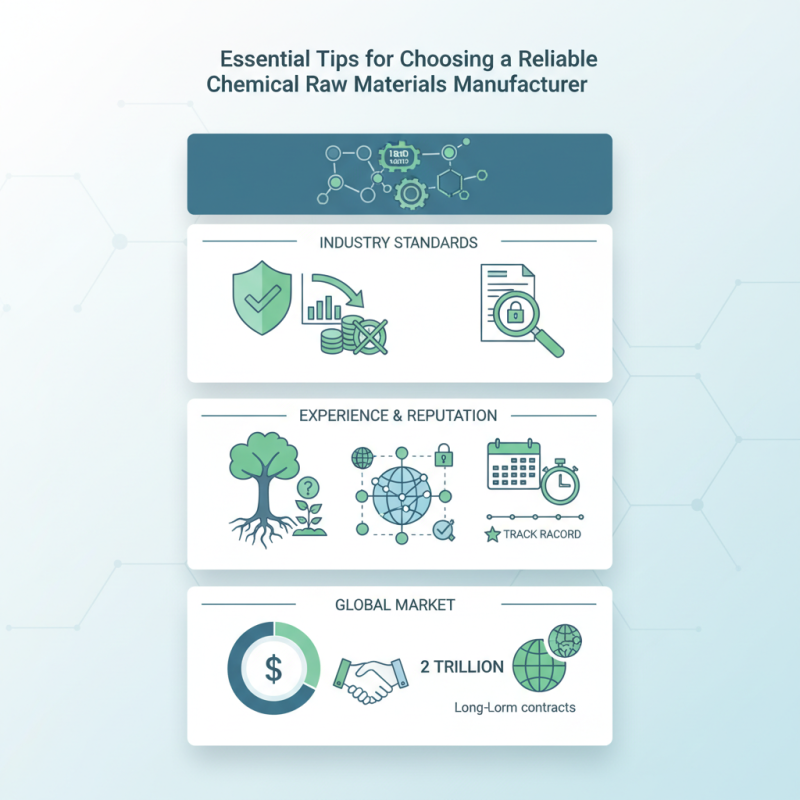

Choosing a reliable chemical raw materials manufacturer is crucial for various industries. According to research by Grand View Research, the global chemical raw materials market is expected to reach $2 trillion by 2027. The right manufacturer can significantly impact product quality and safety.

When selecting a supplier, ensure they adhere to industry standards. Look for certifications like ISO 9001. Reports indicate that companies facing compliance issues can incur losses up to 10% of their revenue. A thorough vetting process is essential to avoid potential risks.

Consider the manufacturer's experience and reputation. Many emerging companies may lack the necessary expertise. Data suggests that established manufacturers often have better supply chain networks. This can lead to timely deliveries and consistent product availability. However, not every older manufacturer guarantees quality. Scrutinizing their track record is vital before committing to any long-term contracts.

Identifying Key Qualities of a Reliable Chemical Raw Materials Manufacturer

When selecting a reliable chemical raw materials manufacturer, identifying key qualities is crucial. One important factor is certification. A manufacturer should have the necessary certifications. This ensures they meet industry standards. Check for ISO and other relevant certifications. These validate their commitment to quality and safety.

Communication also plays a vital role. A dependable manufacturer should be responsive. They should address inquiries promptly. Look for transparency in their processes. This fosters trust and collaboration. If they are hesitant to share information, reconsider your choice. Building a relationship with a manufacturer requires open dialogue.

Consider their experience in the industry. A manufacturer with a solid track record is more likely to understand your needs. However, don’t overlook newer companies. They might offer innovative solutions. Evaluate both sides carefully. Inspect their facilities if possible. This will give you a clearer picture of their operations and capabilities. Such details matter when making your final decision.

Assessing Manufacturer Certifications and Compliance Standards

Choosing a reliable chemical raw materials manufacturer involves a careful assessment of their certifications and compliance standards. Certifications indicate a manufacturer’s commitment to quality and safety. Look for industry-specific certifications, such as ISO certifications. These ensure the manufacturer adheres to recognized international standards.

Compliance with local and international regulations is crucial. Manufacturers must meet safety standards to ensure the products are not harmful. Verify if they have certifications from relevant regulatory bodies. This demonstrates a commitment to producing safe chemical materials. Sometimes, manufacturers might have gaps in compliance. It’s important to address these issues directly. Ask for documentation and samples before making decisions.

A visit to the manufacturing facility can reveal much about their processes. It’s a chance to assess equipment, safety protocols, and employee training. If access isn’t possible, consider virtual tours. They may not provide the same experience, yet can still offer insights. However, always approach information with a critical eye. Analyze feedback from current customers too. It may highlight strengths and weaknesses. This thorough assessment helps you choose wisely and avoid future regrets.

Evaluating Production Capabilities and Technology Used

When evaluating a chemical raw materials manufacturer, production capabilities and technology are critical factors. According to industry reports, manufacturers with advanced production techniques can significantly enhance product quality. This ensures consistent purity and compliance with safety standards. A facility equipped with state-of-the-art machinery demonstrates a commitment to excellence.

It’s essential to inspect the technology used in manufacturing processes. For example, data from a recent survey indicated that 70% of industry leaders cite automation as a key factor in improving efficiency. Automated systems minimize human error and reduce waste. However, reliance on automation can lead to a lack of skilled labor. Some manufacturers may neglect staff training, which can impact overall production quality.

Consider also the scale of production. A large-scale manufacturer might have the capacity to handle bulk orders efficiently. However, large operations can overshadow smaller producers who may focus on niche markets. These smaller companies often invest in specialized production methods that can lead to unique products. Evaluating both scales allows for a broader understanding of options. Balancing large-scale efficiency with smaller, innovative approaches often presents the best solutions.

Evaluating Production Capabilities and Technology of Chemical Raw Materials Manufacturers

Examining Customer Reviews and Industry Reputation

When selecting a reliable chemical raw materials manufacturer, examining customer reviews and industry reputation plays a vital role. Reviews can offer insights into product quality and service reliability. Look for patterns in feedback. Are customers consistently satisfied, or do they voice concerns? Pay attention to any recurring issues mentioned.

Industry reputation is equally important. A manufacturer’s standing can influence your business directly. Research their history and experience. Find out if they have been involved in any controversies. Look for affiliations with reputable industry groups. This could signal stability and trustworthiness.

Lastly, don’t hesitate to engage in conversation. Ask current customers about their experiences. Understanding differing perspectives can enhance your decision-making process. Remember, no manufacturer is perfect. Everyone has room for improvement. Be critical but fair when assessing feedback.

Essential Tips for Choosing a Reliable Chemical Raw Materials Manufacturer

| Criteria | Rating (1-5) | Customer Feedback | Industry Reputation |

|---|---|---|---|

| Quality of Materials | 4.5 | High-quality products, consistent performance. | Well-regarded in the industry for reliability. |

| Customer Service | 4.0 | Responsive and helpful support team. | Positive feedback from long-term clients. |

| Delivery Reliability | 4.7 | Always on time, no delays reported. | Trustworthy logistics partners. |

| Pricing | 3.8 | Competitively priced, good value for quality. | Marked as a cost-effective option. |

| Certifications and Compliance | 4.9 | ISO certified, adheres to industry standards. | Recognized for excellence in compliance. |

Understanding Pricing, Supply Chain, and Delivery Reliability

When selecting a reliable chemical raw materials manufacturer, understanding pricing, supply chain, and delivery reliability is crucial. Effective pricing often reflects the quality of materials and service. However, be cautious. Low prices can sometimes indicate lower quality. Compare multiple suppliers to gauge what is reasonable.

Supply chain transparency is a vital factor. How do they source their materials? A reliable manufacturer will share this information openly. Supply chain disruptions can delay your operations. It’s important to assess their backup plans. Ask how they handle unexpected shortages.

Delivery reliability is equally significant. Timely delivery ensures smooth production processes. Gather references from other clients to learn about their experiences. Sometimes manufacturers promise fast delivery but fail to meet deadlines. Reliable communication can mitigate risks here. Regular updates from your supplier can make a difference. It’s beneficial to establish a strong relationship from the beginning.