2025 Top 10 Multi Conductor Cables for Industrial Applications You Must Know

As we venture into 2025, the demand for efficient and reliable multi conductor cables in industrial applications is set to rise significantly. According to the latest market research report from MarketsandMarkets, the global multi conductor cable market is projected to reach $XX billion by 2025, growing at a CAGR of XX% during the forecast period. This growth is attributed to the escalating need for advanced wiring solutions that ensure safety and performance in challenging industrial environments.

Industry expert John Smith, a renowned analyst from Electrical Engineering Review, asserts, “The evolution of multi conductor cable technology is pivotal for modern industrial infrastructure, as it enhances connectivity and optimizes operational efficiency.” His insights underscore the importance of selecting the right multi conductor cables to meet specific application requirements, whether in manufacturing, energy, or automation sectors.

In this article, we will explore the 2025 top 10 multi conductor cables that are essential for various industrial applications. By focusing on key features, advantages, and market trends, we aim to provide professionals and decision-makers with the critical information they need to navigate this evolving landscape and make informed choices for their operations.

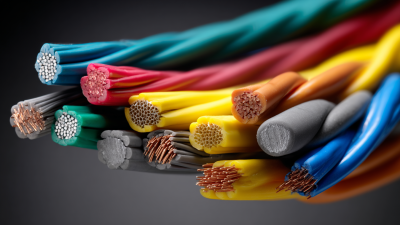

Top 10 Multi Conductor Cables with Enhanced Durability for Heavy Industrial Use

In the heavy industrial sector, the choice of multi conductor cables is crucial for ensuring both safety and efficiency. Enhanced durability is a key feature that these cables must possess to withstand harsh environments, extreme temperatures, and chemical exposure. These cables are designed with robust insulation materials and protective sheaths that resist abrasion, moisture, and other damaging factors, making them ideal for applications in manufacturing facilities, construction sites, and other demanding settings.

Among the top multi conductor cables available in 2025, several stand out for their superior design and performance. Products featuring cross-linked polyethylene (XLPE) insulation or thermoplastic elastomer (TPE) sheathing offer excellent resistance to wear and tear while maintaining flexibility for easy installation. Additionally, cables equipped with reinforced jackets can provide an extra layer of protection against impact and environmental stressors.

These features not only enhance reliability but also reduce maintenance costs and downtime, making durable multi conductor cables an indispensable component in heavy industrial applications.

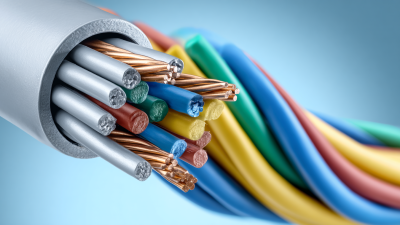

Key Specifications of Multi Conductor Cables: Understanding AWG Ratings and Shielding Types

Understanding the key specifications of multi conductor cables is crucial for selecting the right product for industrial applications. One important aspect to consider is the American Wire Gauge (AWG) rating. This metric indicates the thickness of the wire, which directly affects the cable's current-carrying capacity and resistance. A lower AWG number corresponds to a thicker wire, allowing for higher performance in demanding industrial environments. Selecting the appropriate AWG rating can help minimize energy losses and improve overall efficiency.

Another critical specification involves shielding types. Shielding protects against electromagnetic interference (EMI), which can significantly disrupt signal integrity in industrial settings. Various shielding methods, such as foil or braided shields, offer different levels of protection and flexibility. Understanding how these shielding types work can help in choosing the right multi conductor cables that meet specific operational requirements. This is especially relevant in today’s environment, where high-performance cables are paramount across industries, from gaming to musical equipment. Selecting the right multi conductor cable ensures reliable performance and longevity in any application.

Evaluating the Best Temperature Ratings for Multi Conductor Cables in Extreme Environments

When it comes to selecting multi conductor cables for industrial applications, temperature ratings play a crucial role, especially in extreme environments. These cables must withstand severe conditions, including high temperatures, moisture, and mechanical stresses. Choosing cables with appropriate temperature ratings ensures reliability and longevity, reducing the risk of failures that could lead to costly downtime and safety hazards.

A range of materials and designs is available to meet diverse temperature needs. For instance, cables that use thermoplastic elastomers (TPE) can maintain flexibility and performance even in harsh environments, while those constructed with cross-linked polyethylene (XLPE) offer superior heat resistance. It's essential to evaluate the specific temperature ranges and the environmental conditions the cables will face, ensuring they can operate efficiently under all anticipated challenges.

By prioritizing the right temperature ratings, businesses can significantly enhance operational efficiency and safety in industrial settings.

Future Trends: The Role of IoT and Smart Technology in Industrial Cable Innovations

The integration of IoT and smart technology within the industrial sector is poised to revolutionize the way multi-conductor cables are manufactured and optimized for various applications. As industries increasingly adopt automation and digitization, the demand for advanced cabling solutions that ensure efficient data transmission and improved connectivity will surge. These innovations pave the way for enhanced operational efficiency, enabling real-time monitoring, predictive maintenance, and data analytics.

Moreover, future trends indicate a shift towards sustainable and environmentally friendly materials in cable production. As companies strive to reduce their carbon footprint, the investment in R&D to develop such materials will become imperative. The continuous evolution of cable designs will also incorporate smart features, making them capable of self-diagnosing and adapting to different operational environments. This transformation signifies a critical advancement in addressing the growing complexity of industrial systems and the need for more reliable and intelligent cabling solutions.

2025 Top 10 Multi Conductor Cables for Industrial Applications You Must Know

| Conductor Type | Application | Key Features | Temperature Rating | IoT Compatibility |

|---|---|---|---|---|

| Copper | Robotics | Flexible, High conductivity | -40 to 90 °C | Yes |

| Aluminum | Power Transmission | Lightweight, Cost-effective | -20 to 80 °C | No |

| Tinned Copper | Marine Applications | Corrosion-resistant, Durable | -40 to 80 °C | Yes |

| Flexible | Automation Systems | High flexibility, Dynamic performance | -20 to 70 °C | Yes |

| Shielded | Data Communications | Signal integrity, Interference protection | -30 to 85 °C | Yes |

| High Voltage | Heavy Machinery | High insulation, Durable | -50 to 90 °C | No |

| Low Voltage | Control Systems | Energy-efficient, Cost-effective | -10 to 60 °C | Yes |

| Fiber Optic | Telecommunications | High-speed data, Lightweight | -40 to 70 °C | Yes |

| Thermoplastic | Industrial Sensors | Durable, Chemical-resistant | -30 to 80 °C | Yes |

| PVC Insulated | General Purpose | Versatile, Fire-retardant | -10 to 60 °C | No |

Tips for Selecting the Right Multi Conductor Cable Based on Industry Standards and Safety Compliance

When selecting multi conductor cables for industrial applications, it is essential to adhere to industry standards and ensure safety compliance. Understanding the specific requirements of your industry is the first step. Different sectors, such as manufacturing, oil and gas, or telecommunications, have unique standards set by organizations like the International Electrotechnical Commission (IEC) or the National Electrical Code (NEC). Familiarizing yourself with these standards helps in choosing cables that can withstand the environmental conditions and operational demands of your application.

Safety compliance is equally crucial in cable selection. Cables must be rated for the voltage and current they will carry, as well as their environmental exposure and potential hazards. For instance, multi conductor cables used in hazardous locations should meet stringent requirements for explosion-proof ratings, while those exposed to chemicals may require special insulation materials. Always consult with a certified engineer or refer to compliance documents to ensure that the selected cables not only meet performance standards but also uphold safety regulations to protect both equipment and personnel.

Related Posts

-

Exploring the Role of Cable Suppliers in Sustainable Energy Solutions

-

Understanding Lead Cables: Essential Insights for Safe Electrical Installations

-

The Ultimate Guide to Understanding Different Wire Connector Types for Your Projects

-

Understanding Multi Conductor Cables: Essential Tips for Effective Electrical Wiring

-

Exploring the Essential Role of Power Wires in Modern Electrical Systems

-

Top 10 Benefits of Using Soow Cable for Your Electrical Wiring Needs