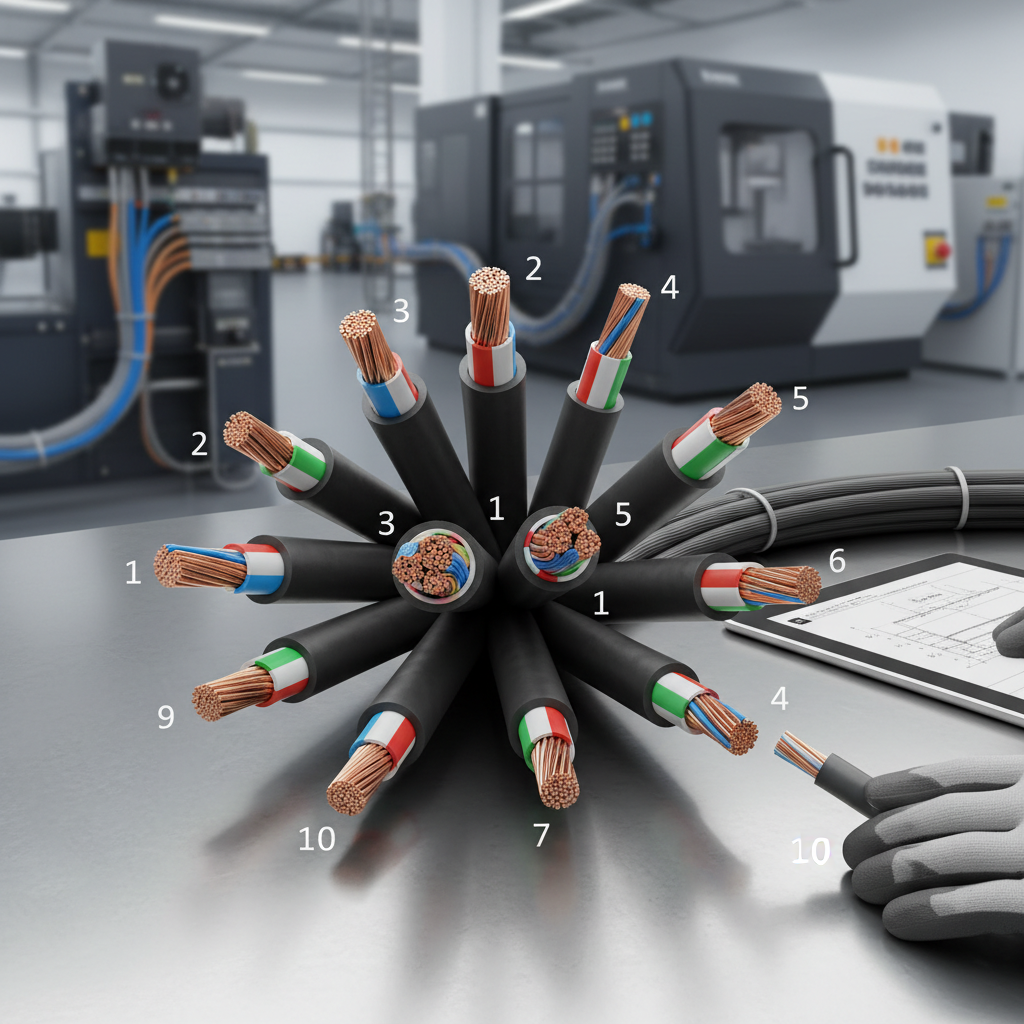

Top 10 Control Cable Types for Optimal Performance in Industrial Applications

In the fast-evolving landscape of industrial applications, the integral role of control cables cannot be overstated. These cables are essential for transmitting signals and powering equipment, ensuring smooth operations across various sectors, including manufacturing, energy, and automation. According to the latest report from the International Cable Manufacturers Federation (ICMF), the demand for control cables is projected to increase by 12% annually, reaching $14 billion by 2026. This indicates a significant shift towards more advanced, reliable solutions that cater to an evolving technological environment.

Industry experts emphasize the importance of selecting the right type of control cable to maximize performance and safety. As Dr. Jane Smith, a leading figure in the cable innovation field, succinctly puts it, "The choice of control cable can significantly impact the efficiency and safety of industrial processes." Given the critical nature of these components, understanding the various types of control cables and their specific applications becomes paramount for engineers and decision-makers alike. This article presents a curated list of the top 10 control cable types designed to enhance operational efficiency in industrial environments, aiming to facilitate informed choices that align with contemporary technological demands.

Types of Control Cables Revolutionizing Industrial Automation in 2025

As industrial automation evolves, the demand for advanced control cables is set to revolutionize various applications by 2025. Emerging technologies, such as the Industrial Internet of Things (IIoT) and smart manufacturing, are driving the need for cables that can handle high data transmission rates and withstand harsh environmental conditions. According to a recent market report by ResearchAndMarkets, the global control cable market is projected to grow at a CAGR of 6.5% from 2023 to 2028, underscoring the importance of selecting the right cable types for maximizing operational efficiency.

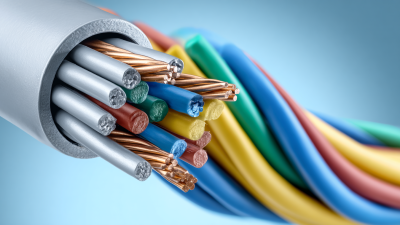

Among the types leading this transformation are shielded cables designed to mitigate electromagnetic interference (EMI), crucial for maintaining signal integrity in complex environments. Additionally, hybrid control cables that integrate power and data transmission capabilities are becoming increasingly popular, allowing for streamlined installations and reduced material costs. Reports indicate that end-users in sectors such as manufacturing and logistics are already benefiting from these innovative cable solutions, with improvements in automation speed and reliability. Thus, the future of industrial automation heavily relies on the continual development and adoption of specialized control cables, ensuring optimal performance and scalability for diverse applications.

Essential Features of Control Cables for Enhanced Performance in Harsh Environments

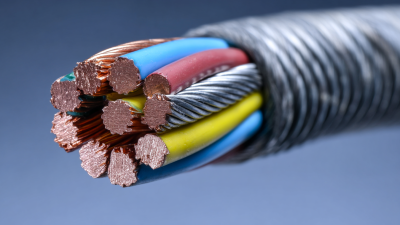

In industrial applications, control cables play a crucial role, particularly in harsh environments where reliability and performance are paramount. The essential features of control cables designed for such conditions include robustness against mechanical stress, excellent resistance to chemical corrosion, and the ability to withstand extreme temperatures. These attributes ensure that the cables can maintain performance and longevity, minimizing downtime and maintenance costs in industrial settings.

Recent advancements highlight the integration of innovative materials and design techniques, enhancing the durability and functionality of control cables. For instance, the use of anti-noise triboelectric sensors can significantly improve the signal clarity in noisy industrial environments, promoting better human-machine collaboration. Furthermore, the development of high-performance components such as MEMS pressure sensors and advanced thermal management solutions demonstrates a trend towards more resilient and efficient technologies. These innovations not only enhance the operational capacity of control cables but also contribute to a more sustainable and reliable industrial infrastructure.

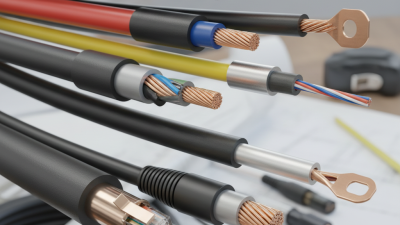

Comparative Analysis of Copper vs. Fiber Optic Control Cables in Industry

When it comes to industrial applications, the choice between copper and fiber optic control cables can significantly impact performance. Copper cables have long been the standard due to their electrical conductivity and cost-effectiveness. They perform exceptionally well in environments requiring reliable power transmission and are less susceptible to external interference. However, they can be limited by distance, as signal quality diminishes over long runs.

On the other hand, fiber optic cables excel in data transmission over vast distances, offering higher bandwidth and immunity to electromagnetic interference. This makes them especially suitable for industries that demand high-speed communication and data integrity. Although the initial investment is higher for fiber optics, their ability to handle larger data volumes and longer distances often justifies the expense in the long run.

**Tips:** Consider the environment where the cables will be installed. If your application involves high levels of interference, fiber optics may be the best choice. Also, evaluate the future scalability of your infrastructure; investing in fiber now might save costs and headaches as the technology demands evolve. Always conduct a thorough analysis of both cable types to ensure optimal performance based on your specific industrial needs.

Comparative Analysis of Copper vs. Fiber Optic Control Cables

Innovative Design Trends in Control Cables for Improved Efficiency and Safety

In today's fast-paced industrial environment, the design of control cables is evolving to enhance both efficiency and safety. Innovative materials, such as thermoplastic elastomers and advanced composites, are being utilized to create cables that can withstand extreme conditions. These materials offer greater flexibility and resistance to abrasion, ensuring reliable performance even in challenging settings. Additionally, manufacturers are increasingly focusing on reducing the cable's weight while maintaining its durability, which facilitates easier installation and improved handling in complex machinery.

Another significant trend in control cable design is the integration of smart technology. With the rise of Industry 4.0, cables equipped with sensors can monitor performance in real-time, detecting potential issues before they escalate into costly failures. This connectivity enhances operational safety by providing immediate feedback to operators and maintenance teams. Furthermore, the use of color-coded sheathing and labeling simplifies identification and maintenance, leading to quicker troubleshooting and reduced downtime. These cutting-edge design trends are not only transforming the functionality of control cables but also setting new standards for industrial efficiency and safety compliance.

Future of Control Cables: Emerging Technologies and Their Industrial Impact

The future of control cables in industrial applications is significantly influenced by the growing emphasis on renewable energy sources and sustainable practices. As industries pivot towards greener solutions, the demand for high-performance control cables designed to withstand the rigors of renewable energy projects, such as solar and wind, is expected to surge. A report from an industry research firm indicates that the market for control cables in renewable energy is projected to grow at a compound annual growth rate (CAGR) of over 7% from 2023 to 2028. This uptick is driven by the need for efficient power transmission and the integration of advanced controls to optimize energy management.

In addition, the rise of emerging technologies, including artificial intelligence and spatial computing, will further reshape the landscape of industrial applications by 2026. These technological advancements not only enhance operational efficiency but also facilitate real-time monitoring and predictive maintenance, significantly reducing downtime and operational costs. The engineering and construction sectors stand to benefit immensely from these innovations, as they can leverage modern control solutions to streamline processes and improve project outcomes. As industries adapt to these changes, the demand for specialized control cables that meet stringent performance criteria will become paramount, emphasizing the importance of selecting the right cable types for optimal performance.

Top 10 Control Cable Types for Optimal Performance in Industrial Applications - Future of Control Cables: Emerging Technologies and Their Industrial Impact

| Cable Type | Jacket Material | Conductor Material | Temperature Range (°C) | Typical Applications |

|---|---|---|---|---|

| PVC Control Cable | PVC | Copper | -10 to 70 | Industrial machinery, HVAC |

| XLPE Control Cable | XLPE | Aluminum | -30 to 90 | Oil and gas industry |

| Armored Control Cable | PVC | Copper | -20 to 70 | Production facilities, mining |

| Silicone Rubber Control Cable | Silicone | Copper | -60 to 200 | High-temperature applications |

| TPU Control Cable | TPU | Copper | -40 to 90 | Automation and robotics |

| Shielded Control Cable | PVC | Copper | -10 to 70 | Data transmission systems |

| FEP Control Cable | FEP | Copper | -200 to 180 | Chemical processing |

| Ethernet Control Cable | LSZH | Copper | -40 to 80 | Networking solutions |

| Multi-pair Control Cable | PVC | Copper | -10 to 70 | Telecommunications |

| Fiber Optic Control Cable | LSZH | Silica | -40 to 70 | High-speed data transmission |

Related Posts

-

2025 Guide to Choosing the Right Wire and Cable for Your Projects

-

Essential Automotive Cable Maintenance Tips for a Smooth Ride

-

Exploring the Essential Role of Power Wires in Modern Electrical Systems

-

Understanding Multi Conductor Cables: Essential Tips for Effective Electrical Wiring

-

What is Armoured Cable? Understanding Its Types, Benefits, and Applications

-

Top 10 Benefits of Using Soow Cable for Your Electrical Wiring Needs