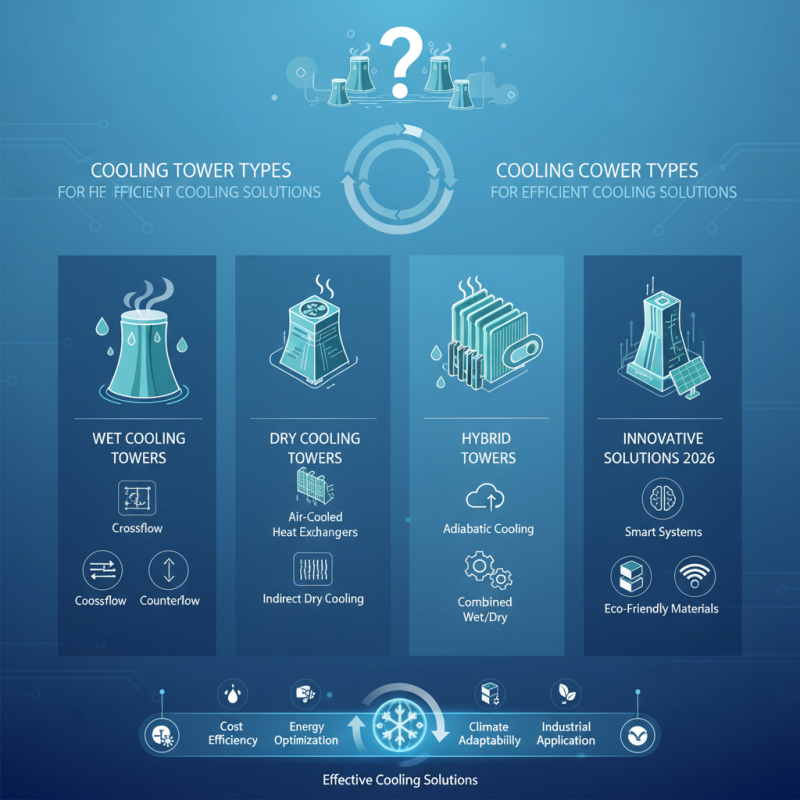

Top Cooling Tower Types for Efficient Cooling Solutions in 2026?

In 2026, the demand for effective cooling solutions continues to grow. cooling towers play a vital role in various industries. Their design and efficiency significantly influence energy consumption.

Different types of cooling towers have emerged. Each tower serves specific needs and environments. Some are more efficient, while others may be cheaper. Understanding these options is crucial for industries aiming to optimize costs and performance.

As we explore the top cooling tower types, we find a mix of traditional and innovative solutions. Selecting the right cooling tower requires careful thought. Efficiency alone does not guarantee effectiveness. Consider factors like climate and application. Balancing these elements often presents challenges. Facing these choices can lead to unexpected outcomes.

Overview of Cooling Towers and Their Importance in Industrial Applications

Cooling towers play a crucial role in various industrial processes. They primarily help regulate temperatures, ensuring efficient operation of machinery. By dissipating excess heat, they contribute to energy savings and prolonged equipment lifespan. This functionality is especially vital in industries like power generation, manufacturing, and HVAC systems.

Different types of cooling towers exist, such as natural draft and mechanical draft. Each type has distinct advantages and limitations. For instance, natural draft towers rely on the natural flow of air, needing less mechanical energy. However, they often occupy larger spaces, posing a challenge in urban settings. On the other hand, mechanical draft towers are more space-efficient but require additional power to operate fans.

Choosing the right cooling tower can be complex. It involves understanding site-specific conditions and operational requirements. Factors like water quality, ambient temperature, and energy costs are critical. Many companies overlook these aspects, leading to inadequate cooling solutions. Reflection on past implementations can guide better decisions for future projects.

Types of Cooling Towers: Natural Draft vs. Mechanical Draft

Cooling towers play a crucial role in industrial applications. They help dissipate heat from machinery and processes. Among various types, natural draft and mechanical draft cooling towers stand out.

Natural draft cooling towers rely on buoyancy. Warm air rises naturally, creating a draft. This design often appears in larger facilities. However, their efficiency can vary with external temperatures. On hot days, they might struggle to maintain optimal cooling. Proper maintenance is vital for consistent performance.

Mechanical draft cooling towers use fans to push air through. They are more versatile and can fit in smaller spaces. Their efficiency is less dependent on weather conditions. However, they often consume more energy. This could increase operational costs over time. Balancing energy use and cooling needs is essential.

Innovative Materials and Technologies in Modern Cooling Towers

The cooling tower industry is evolving rapidly, driven by innovative materials and technologies. Recent studies indicate that composite materials reduce weight significantly. This change enhances structural integrity while improving thermal performance. In fact, recent reports show a 15% increase in efficiency with advanced materials.

Modern cooling towers often utilize hybrid designs, combining natural and mechanical cooling. This method optimizes energy consumption. A notable report suggests that such designs can reduce energy use by up to 30%. However, these systems require careful planning and may lead to increased initial costs.

Emphasizing sustainability, some towers now incorporate smart technologies. Sensors monitor performance in real-time. This feature helps maintain optimal conditions efficiently. It also allows for predictive maintenance, which can prevent costly shutdowns. Such advancements are promising, yet pose challenges in integration with existing systems.

Energy Efficiency and Environmental Considerations in Cooling Towers

Cooling towers are crucial for maintaining efficient thermal management in various industries. Their role in energy efficiency cannot be understated. Modern designs aim to minimize water and power consumption. However, not all cooling towers meet these energy standards. Some older technologies lag behind, leading to excessive waste. It's vital to assess each type's efficiency thoroughly.

Environmental considerations are becoming increasingly important. Cooling towers can impact local ecosystems through water usage and chemical treatments. Innovative solutions focus on reducing these impacts. Some systems now incorporate filtration to limit chemical usage. A promising trend includes the use of renewable energy sources. Solar power can help lower operational costs while enhancing sustainability.

Decision-makers must reflect on their choices. It’s easy to opt for traditional systems, but they may not always be the best fit. The push for energy-efficient cooling solutions is growing. The challenge lies in balancing efficiency with environmental responsibility. Continuous improvement is essential in this evolving landscape.

Top Cooling Tower Types for Efficient Cooling Solutions in 2026

| Cooling Tower Type | Cooling Capacity (kW) | Efficiency Rating | Water Consumption (L/h) | Environmental Impact |

|---|---|---|---|---|

| Closed-Circuit Cooling Tower | 300 - 1500 | High | 20 - 50 | Low emissions; minimal water wastage |

| Open-Circuit Cooling Tower | 400 - 2000 | Moderate | 50 - 150 | Higher water loss; potential for plume |

| Hybrid Cooling Tower | 250 - 1200 | Very High | 30 - 70 | Reduced water usage; eco-friendly |

| Evaporative Cooling Tower | 500 - 2500 | High | 40 - 100 | Efficient but involves water usage |

| Counterflow Cooling Tower | 350 - 1600 | High | 25 - 60 | Efficient; can have noise issues |

Future Trends and Predictions for Cooling Tower Designs in 2026

In 2026, cooling tower designs will evolve significantly. Efficiency will be key. Engineers will focus on enhancing airflow and energy use. New materials could play a role. Lightweight and durable options may emerge. This will help reduce maintenance and operational costs.

Tips: Consider energy audits. Regular checks can identify leaks. Improper airflow could waste energy. Small fixes often lead to big savings.

Sustainability will also shape the future. Many will turn to eco-friendly materials. Water conservation methods will gain traction. Innovations in design could lead to less water use.

Monitoring technology is vital. Smart sensors will track performance. These tools can help in real time. Understand the limitations of current systems. Continuous improvement is essential in this sector.