Top Electrical Connectors for Reliable Performance in Your Projects

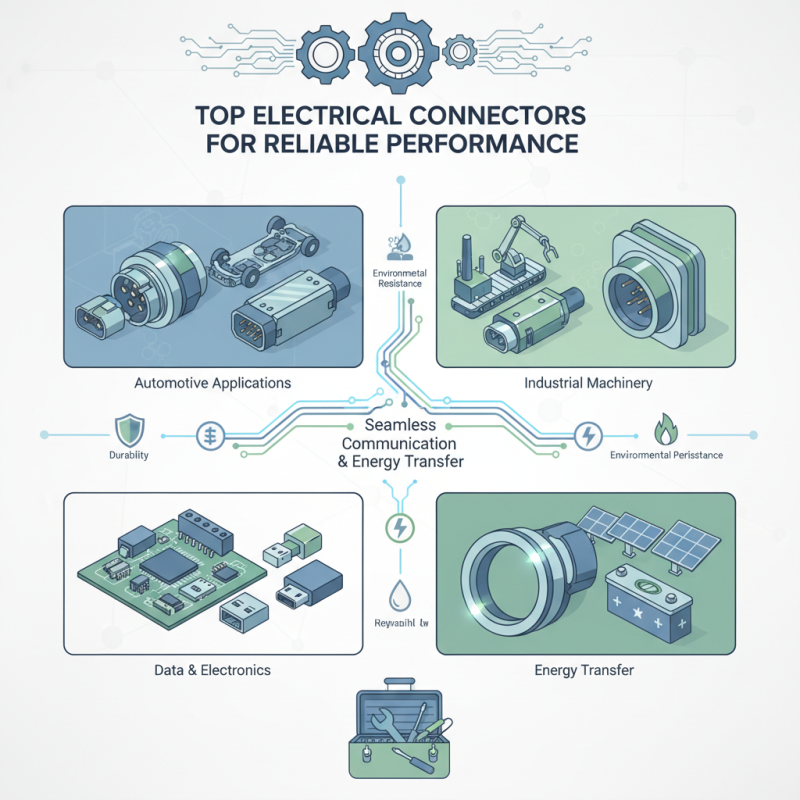

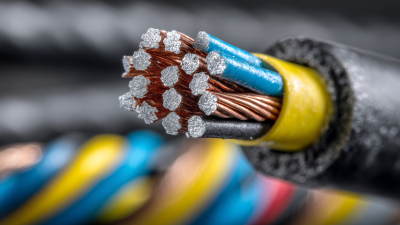

In today's technologically driven world, the importance of electrical connectors cannot be overstated. These essential components serve as the backbone of countless devices and systems, facilitating seamless communication and energy transfer between various electronic parts. As projects grow in complexity and the demand for reliability increases, selecting the right electrical connectors becomes crucial for both performance and longevity.

From automotive applications to industrial machinery, the variety of electrical connectors available on the market caters to diverse needs, ensuring that each connection is robust and efficient. With advancements in technology, modern electrical connectors are designed not only for ease of use but also for enhanced durability, resistance to environmental factors, and superior electrical performance. In this article, we will explore some of the top electrical connectors that stand out for their reliability and effectiveness, highlighting the features that make them indispensable in various applications. Whether you are an engineer, a technician, or a DIY enthusiast, understanding these components will empower you to make informed choices for your projects.

Understanding the Importance of Electrical Connectors in Projects

Electrical connectors play a crucial role in ensuring the reliability and efficiency of various projects. In any electrical system, connectors serve as the interface that allows different components to communicate and function synergistically. A well-designed connector can prevent signal loss and reduce the potential for short circuits, which is instrumental in maintaining the performance of electrical systems. Therefore, understanding the significance of choosing the right electrical connectors cannot be overstated, as they can directly impact the longevity and robustness of the entire project.

Moreover, the selection of electrical connectors should align with the specific requirements of each application. Factors such as environmental conditions, load capacity, and mechanical stress must be carefully considered. For instance, connectors used in outdoor settings should be weatherproof and resistant to corrosion, while those in high-vibration environments should provide secure locking mechanisms to prevent disconnection. By prioritizing the right connectors tailored to project needs, engineers and project managers can ensure seamless integration, fostering enhanced functionality and safety throughout the project lifecycle.

Types of Electrical Connectors: A Comprehensive Overview

When it comes to electrical connectivity, understanding the various types of electrical connectors is essential for ensuring reliable performance in any project. According to a report by the International Electrotechnical Commission (IEC), the global electrical connector market is projected to reach $xx billion by 2027, emphasizing the growing importance of selecting the right connectors. Among the popular types are terminal block connectors, which provide robust connections for wire-to-board applications, and circular connectors, often used in industrial settings for their durability and ease of use.

Another critical category is the ribbon connectors, commonly found in consumer electronics. A study from Allied Market Research highlights that the demand for ribbon connectors is expected to surge by over 5% annually due to the rise of automation in manufacturing processes. Additionally, the use of coaxial connectors in telecommunications is on the rise, driven by the increasing need for high-speed data transmission. By understanding these connector types and their applications, engineers can optimize their projects for both performance and reliability.

Top Electrical Connectors for Reliable Performance in Your Projects

| Connector Type | Application | Current Rating | Voltage Rating | Material |

|---|---|---|---|---|

| Wire-to-Wire Connectors | Automotive wiring | 30A | 600V | Copper |

| Wire-to-Board Connectors | Consumer electronics | 10A | 300V | Plastic, Copper |

| USB Connectors | Computers and peripherals | 5A | 20V | Plastic, Gold plated contacts |

| DT Series Connectors | Industrial applications | 15A | 250V | Aluminum, Copper |

| RCA Connectors | Audio and video equipment | 5A | 75V | Brass, Plastic |

Key Features to Look for in Reliable Electrical Connectors

When selecting electrical connectors for your projects, several key features are essential to ensure reliable performance. First and foremost, look for connectors that have a high current rating. This rating indicates the maximum amount of current the connector can handle without overheating, which is crucial for maintaining safety and efficiency. Additionally, consider connectors designed with durable materials that can withstand harsh environmental conditions, such as moisture, temperature fluctuations, and mechanical stress. This durability can significantly extend the longevity of the connectors in various applications.

Another important feature to evaluate is the ease of installation. Connectors that offer clear labeling and intuitive designs streamline the assembly process, reducing the risk of errors during installation. Furthermore, compatibility with different wire gauges and types can provide added versatility, making it easier to incorporate the connectors into diverse projects. Lastly, look for connectors that provide reliable strain relief to prevent wire breakage and ensure a stable connection over time. Prioritizing these features will help you choose electrical connectors that deliver dependable performance throughout your project's lifecycle.

Top Electrical Connectors Performance Analysis

Top Brands and Their Best Performing Electrical Connectors

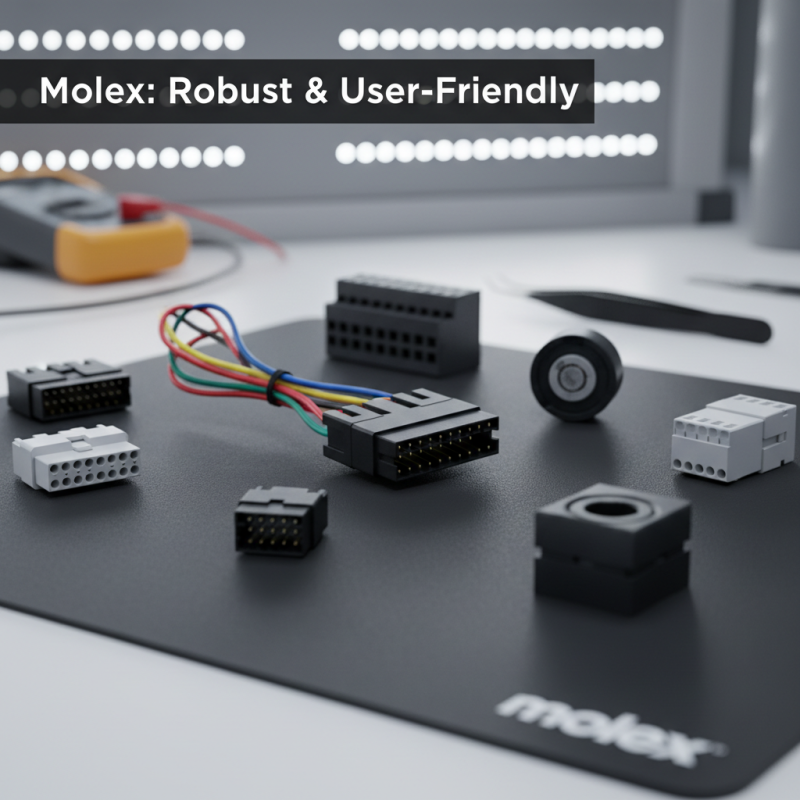

When it comes to selecting electrical connectors for reliability and performance, understanding the top brands is crucial. Companies like Molex, TE Connectivity, and Amphenol are leaders in producing connectors that ensure longevity and efficiency in various applications. Molex offers a wide range of connector options that cater to both commercial and industrial environments, known for their robustness and ease of use. TE Connectivity specializes in high-performance connectors designed for harsh conditions, making them ideal for automotive and aerospace sectors. Amphenol is renowned for its innovative solutions, particularly in telecommunications, providing connectors that are not only durable but also support high-speed data transfer.

Tips for choosing the right electrical connectors include assessing the specific needs of your project, such as the operating environment and electrical load. Always consider the material of the connectors; for harsh environments, look for corrosion-resistant options. Additionally, make sure to check the compatibility with existing systems to avoid installation issues. Investing in quality connectors from these top brands will ultimately enhance the reliability of your projects and reduce maintenance costs over time.

Best Practices for Selecting and Installing Electrical Connectors

When selecting and installing electrical connectors, it's crucial to adhere to best practices to ensure reliable performance in your projects. According to industry reports, nearly 30% of electrical failures in manufacturing are attributed to improper connector selection and installation. The importance of quality connectors cannot be overstated; they facilitate the flow of electricity, and any inefficiency or failure can lead to significant downtime and costs.

One tip for selecting connectors is to assess the environmental conditions they will face. For instance, connectors used in harsh environments should be rated for moisture and temperature variations. Moreover, proper sizing is essential; connectors that are too small can overheat, while those that are too large may introduce resistance. During installation, make sure to follow torque specifications to avoid damage, which can compromise performance.

To further enhance reliability, consider investing in connectors that integrate advanced technologies, such as those incorporating AI for predictive maintenance. This approach, evidenced by recent advancements in industrial application, can help detect issues before they lead to failures. By focusing on quality and adhering to best practices, you can ensure that your projects remain productive and efficient.

Related Posts

-

Maximizing Safety and Efficiency: The Essential Guide to Choosing Electrical Wire Connectors in 2023

-

Exploring the Advantages of 4 Core Cable in Modern Electrical Installations and Its Impact on Efficiency

-

What is Armoured Cable? Understanding Its Types, Benefits, and Applications

-

Understanding the Essential Role of Wire and Cable in Modern Technology Systems

-

Exploring the Role of Cable Suppliers in Sustainable Energy Solutions

-

2025 Top 10 Marine Cable Innovations Transforming Global Connectivity