Top Wire Connectors: Choosing the Best Types for Your Projects

When it comes to ensuring safe and reliable electrical connections in your projects, the choice of wire connector plays a crucial role. Wire connectors are essential components that provide a secure method for joining electrical wires, making them indispensable not only for professional electricians but also for DIY enthusiasts. With a wide variety of wire connectors available on the market, understanding which types are best suited for your specific applications can significantly impact the effectiveness and safety of your wiring system.

In this guide, we will explore the different types of wire connectors, highlighting their features, advantages, and best-use scenarios. From traditional crimp connectors to modern push-in types, each connector serves a unique purpose and is designed to meet various electrical requirements. By considering factors such as wire gauge, application environment, and ease of installation, you can make informed decisions that enhance the quality and longevity of your electrical connections. Ultimately, selecting the right wire connector will not only facilitate your project's success but also ensure compliance with electrical standards, providing peace of mind throughout the process.

Top Wire Connector Types: An Overview of Options and Features

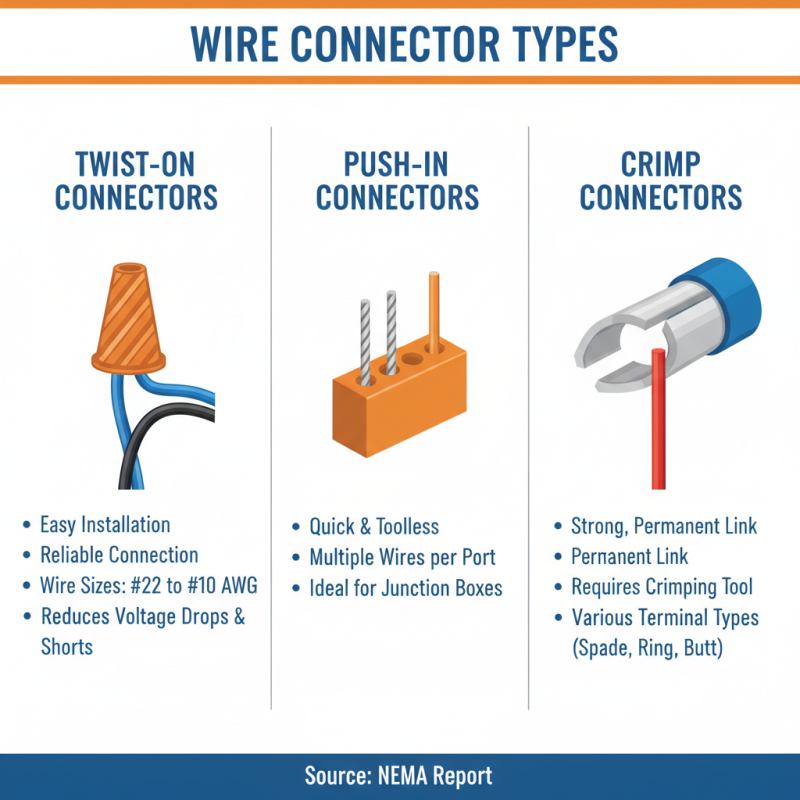

When selecting wire connectors for your projects, understanding the various types available and their distinct features is essential. Wire connectors can be categorized into several types: twist-on connectors, push-in connectors, and crimp connectors, each serving different applications. According to a report from the National Electrical Manufacturers Association (NEMA), twist-on connectors are widely used due to their straightforward installation and reliability, accommodating wire sizes ranging from #22 to #10 AWG. These connectors offer a secure connection, reducing the risk of voltage drops and short circuits.

Push-in connectors have gained popularity for their ease of use, especially in scenarios where speed is critical. Data from the International Electrotechnical Commission (IEC) indicates that push-in connectors can significantly reduce installation time in both residential and commercial settings. They generally support a variety of wire gauges and are built for quick insertion without requiring special tools. Meanwhile, crimp connectors provide a sturdy and long-lasting connection, often used in automotive applications. A study by the Society of Automotive Engineers (SAE) shows that crimped connections, when done correctly, can last longer than traditional soldered joints, making them ideal for high-vibration environments.

Overall, selecting the right type of wire connector hinges on the specific requirements of your project, including the environment, type of wiring, and installation method. Familiarizing yourself with the options and associated features can lead to more efficient and safe electrical connections.

Understanding Wire Connector Ratings: Amperage and Voltage Considerations

When selecting wire connectors for your projects, understanding the ratings for amperage and voltage is crucial. Amperage, or current rating, refers to the maximum amount of electrical current a connector can safely handle. Exceeding this limit can lead to overheating, potential failure, or even fire hazards. It's essential to choose connectors that match or exceed the amperage requirements of your application to ensure safe and efficient operation.

Voltage ratings indicate the maximum voltage a connector can withstand before breaking down. This is particularly important in high-voltage applications where pressures can be significant. Keeping voltage ratings in mind helps in avoiding insulation failure and ensures that the connectors will perform reliably under the expected conditions. In many cases, connectors are rated for specific applications, so always refer to the specifications to avoid mismatches that could lead to electrical failures. By paying close attention to these ratings, you can confidently select the right wire connectors that will support the integrity and safety of your electrical projects.

Wire Connector Amperage Ratings

This chart displays the amperage ratings for different wire connectors. Understanding these ratings is crucial for selecting the right connectors for your electrical projects.

Material Matters: Comparing Copper vs. Aluminum Connectors in Performance

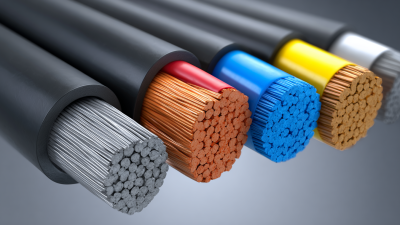

When it comes to wire connectors, the choice of material can significantly influence performance and longevity. Copper connectors are widely recognized for their excellent conductivity, which allows for efficient electrical transmission with minimal energy loss. This makes them an ideal choice for high-performance applications where reliability is critical, such as in industrial settings or critical electrical systems. Additionally, copper's natural corrosion resistance enhances its durability, ensuring a long lifespan even in challenging environments.

On the other hand, aluminum connectors present an advantageous alternative due to their lightweight and cost-effectiveness. Although aluminum does not conduct electricity as efficiently as copper, advancements in connector design have led to improved performance, making aluminum a viable option for many projects. The lower weight of aluminum connectors can also ease installation and reduce the load on existing structures. However, it's essential to consider compatibility with other materials and the potential need for additional maintenance to prevent issues like oxidation, which can impair performance over time. Ultimately, the choice between copper and aluminum connectors will depend on the specific requirements of a project, balancing factors such as conductivity, weight, cost, and environmental conditions.

Application-Specific Connectors: Choosing Based on Project Requirements

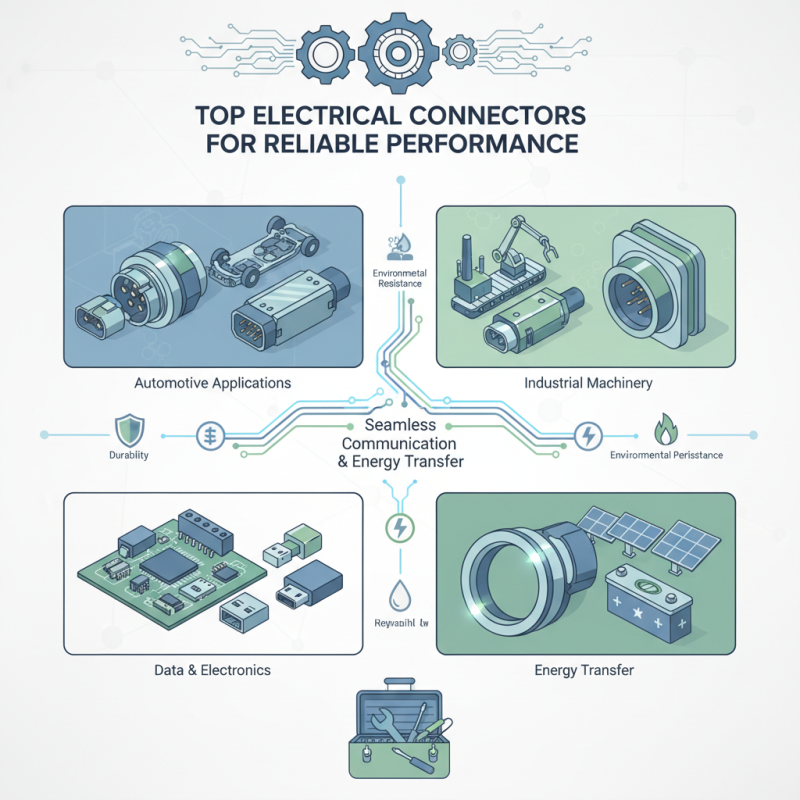

When selecting wire connectors for a project, the specific application requirements play a crucial role in determining the best type for optimal performance. Different projects may require connectors that can withstand varying environmental conditions, such as temperature fluctuations, humidity, or exposure to chemicals. For instance, marine applications demand connectors that are corrosion-resistant and can handle high moisture levels, while automotive projects may require connectors that can endure heat and vibrations.

Furthermore, the electrical specifications of a project also guide the choice of wire connectors. Considerations such as voltage rating, current-carrying capacity, and the number of circuits needed can influence the decision-making process. In applications where space is at a premium, smaller, more compact connectors may be necessary, while larger, more robust connections might be required for heavy-duty electrical systems. Ultimately, understanding the specific demands of your project will ensure that the selected wire connectors provide safety, reliability, and efficiency.

Top Wire Connectors: Choosing the Best Types for Your Projects

| Connector Type | Application | Wire Gauge | Max Voltage | Temperature Rating |

|---|---|---|---|---|

| Butt Connectors | Electrical wiring | 22-10 AWG | 600V | 105°C |

| Splice Connectors | Automotive | 18-12 AWG | 500V | 85°C |

| Ring Terminals | Ground connections | 14-10 AWG | 300V | 105°C |

| Fork Terminals | Battery connections | 16-12 AWG | 600V | 125°C |

| Push-In Connectors | Quick connections | 20-16 AWG | 250V | 75°C |

Cost-Effectiveness and Reliability: Evaluating Connector Longevity and Maintenance

When selecting wire connectors for your projects, cost-effectiveness and reliability should be at the forefront of your decision-making. High-quality connectors can save you money in the long run by minimizing maintenance and replacement costs. A durable connector will endure various environmental conditions, reducing the frequency of repairs and ensuring a steady and safe connection for years. Evaluating the lifespan of different connector types is essential, as some materials are naturally more resistant to corrosion and wear, which directly affects longevity.

Tips for enhancing connector longevity include proper installation techniques, which can prevent stress on the connection points. Ensure that connectors are appropriately rated for the electrical loads they will handle to avoid overheating and potential failures. Regular maintenance checks are also beneficial—inspecting wiring and connectors for signs of wear or damage can help catch problems early, minimizing downtime and repair expenses.

Additionally, consider the environmental conditions where connectors will be used. For outdoor projects, connectors should be resistant to moisture, UV exposure, and other harsh elements. Choosing connectors designed for specific conditions can further enhance reliability and performance, ultimately leading to greater satisfaction and less hassle throughout the lifespan of your project.

Related Posts

-

Maximizing Safety and Efficiency: The Essential Guide to Choosing Electrical Wire Connectors in 2023

-

Top Electrical Connectors for Reliable Performance in Your Projects

-

2025 Top 10 Marine Cable Innovations Transforming Global Connectivity

-

Top 10 Uses of Thermocouple Wire in Industrial Applications

-

2025 Top 10 Multi Conductor Cables for Industrial Applications You Must Know

-

Exploring the Advantages of 4 Core Cable in Modern Electrical Installations and Its Impact on Efficiency