Ultimate Guide to Wire Connector Types You Need to Know?

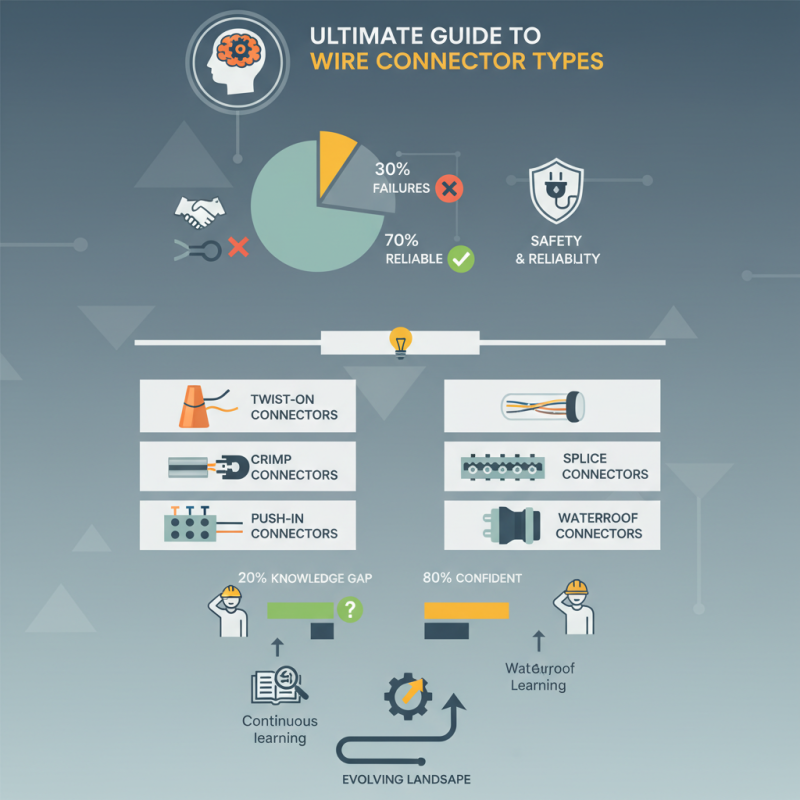

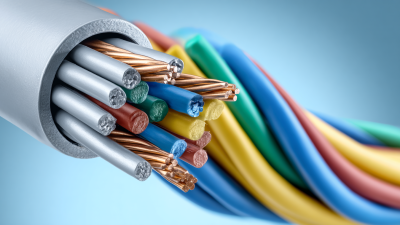

In the ever-evolving world of electrical engineering, understanding wire connector types is crucial. Industry reports reveal that a staggering 30% of electrical failures are linked to inadequate connections. Recognizing the right connector can significantly improve system reliability. As noted by expert Dr. Emily Foster, “Choosing the proper wire connector types can be the difference between safety and failure.” This highlights the importance of informed decisions in connector selection.

The diversity of wire connector types available can be overwhelming. From twist-on connectors to crimp connectors, each has specific applications and advantages. A misstep in selection might lead to poor performance or even hazardous situations. Reports from the Institute of Electrical and Electronics Engineers indicate that 20% of survey respondents lacked fundamental knowledge about these connectors. This knowledge gap is alarming and reflects a need for better education.

Experts advocate for continuous learning regarding wire connector types. While many professionals feel confident in their choices, small oversights can result in significant issues. The journey towards mastering these connectors is ongoing. It requires commitment and critical thinking, as the landscape of electrical components is constantly changing.

Types of Wire Connectors: An Overview of Common Types

Wire connectors are crucial in electrical systems. They ensure secure connections and play a role in safety. Knowing the common types of wire connectors can prevent problems in installations. According to the National Electrical Contractors Association, improper connections cause about 30% of electrical failures.

The most widespread types include twist-on connectors, also known as wire nuts. They are simple and easy to use. Crimp connectors are another common type. They require a tool but provide a more permanent solution. Terminal blocks offer organization, but they can become cumbersome in tight spaces. The choice depends on the application and environment.

However, not all connectors are created equal. Poor-quality connectors may lead to overheating or even fires. A 2020 report by the Electrical Safety Foundation International noted that improper usage can increase risks significantly. It's essential to follow guidelines and select the right connector for each task. Error margins are real, and a moment of carelessness can have serious consequences.

Understanding Wire Gauge and Its Impact on Connector Selection

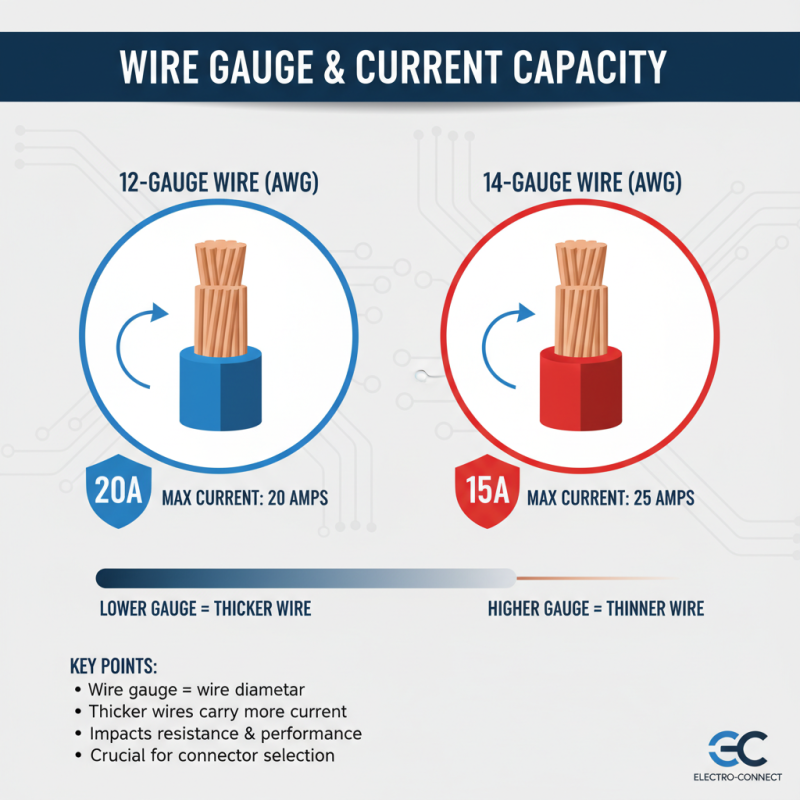

Understanding wire gauge is crucial for selecting the right connector types. Wire gauge refers to the diameter of the wire. This measurement impacts current capacity, resistance, and overall performance. For instance, a lower gauge means a thicker wire. Thicker wires can carry more current. According to the American Wire Gauge (AWG) standard, a 12-gauge wire can safely carry up to 20 amps, while a 14-gauge wire is limited to 15 amps.

Choosing the wrong wire gauge can lead to overheating. This risk is often overlooked. For example, using a 16-gauge wire with a connector rated for only 15 amps may cause failure. This mistake can lead to damaged connections and equipment. Always check gauge specifications before making a selection.

**Tips:** Always verify the load requirements for your project. Ensure that the wire gauge matches the connector specifications. Regularly inspect connections for signs of wear or overheating, as this can indicate an improper gauge use or connector type.

How to Choose the Right Wire Connector for Your Project

Choosing the right wire connector for your project can feel overwhelming. With various types available, the task can be daunting. Think about the specific needs of your project. What are the requirements? Consider the size, the environment, and the electrical load. These factors will guide your decision-making process.

For instance, if you're working with outdoor applications, waterproof connectors are essential. They ensure reliable connections despite rain or humidity. On the other hand, if your project involves high voltage, opt for connectors designed for that purpose. Not all connectors can handle significant loads safely.

Don't rush the selection process. Mistakes can happen. You might find that a connector doesn't fit well or can’t handle the necessary power. Assess your options carefully. It’s wise to have a backup plan. Don't hesitate to seek advice or do more research. Let your project's unique demands drive your choices.

Installation Tips for Various Types of Wire Connectors

When installing wire connectors, proper technique is crucial. Different types of connectors require specific handling. For instance, push-in connectors allow quick connections without special tools. However, they may not be as reliable in high-vibration environments.

According to the National Electrical Manufacturers Association (NEMA), incorrect installation can lead to electrical failures in 30% of cases.

Torque specifications matter too. Over-tightening screw-type connectors can damage the wire. A study from the Institute of Electrical and Electronics Engineers (IEEE) indicates that nearly 25% of electrical faults originate from poorly tightened connections.

Using a torque wrench can help ensure correct tension, further preventing issues.

Inspecting connections after installation is essential. Look for signs of corrosion or heat damage, which could indicate problems. Most manufacturers suggest routine checks twice a year. If overlooked, this could shorten the lifespan of the wiring system. Keeping these tips in mind will enhance the reliability of your electrical connections and prevent future headaches.

Safety Considerations When Using Wire Connectors

When working with wire connectors, safety is crucial. Improper use can lead to electrical shocks or fires. Always ensure that your workspace is dry and well-lit. Wear protective gear, such as gloves and goggles, to prevent injuries. Avoid using connectors in areas where moisture or chemicals are present.

Tips: Double-check the voltage rating of your connectors. Using the wrong type can cause malfunction. Ensure all wire surfaces are clean before connecting. Contaminated wires can create resistance, leading to overheating.

Never force connectors onto wires. A snug fit is essential, but too much pressure can damage the connector or wire. This might lead to future failures or hazards. Take your time to secure each connection properly. Re-evaluating your techniques can help avoid future mistakes.

Ultimate Guide to Wire Connector Types You Need to Know

| Connector Type | Description | Use Cases | Safety Considerations |

|---|---|---|---|

| Twist-On Connector | A plastic cap that twists onto wire connections. | Commonly used in residential electrical wiring. | Ensure wires are stripped properly to avoid short circuits. |

| Crimp Connector | A metal connector that is squeezed onto a wire. | Ideal for automotive and industrial applications. | Check for proper crimping to prevent disconnection. |

| Screw Terminal Connector | Wires are fastened under a screw on a metal plate. | Commonly used in panel wiring and older installations. | Tighten screws securely but avoid over-torquing which can damage wires. |

| Butt Connector | A cylindrical connector that joins two wire ends. | Used in automotive, marine, and general electronics. | Proper insulation is crucial to prevent moisture ingress. |

| Quick Disconnect Connector | Allows easy disconnection of wires. | Frequently used in devices that require frequent maintenance. | Inspect regularly for signs of wear or corrosion. |

Related Posts

-

The Ultimate Guide to Understanding Different Wire Connector Types for Your Projects

-

Maximizing Safety and Efficiency: The Essential Guide to Choosing Electrical Wire Connectors in 2023

-

2026 Top Electrical Wire Connectors for Every Project Need?

-

Top 10 Control Cable Types for Optimal Performance in Industrial Applications

-

Top 10 Benefits of Using Soow Cable for Your Electrical Wiring Needs

-

2025 Top 5 Industrial Electric Wire and Cable Solutions for Every Business Need