What is a wire mesh weaving machine and how does it work?

A wire mesh weaving machine is a complex yet fascinating device. It plays a vital role in various industries, particularly in construction and manufacturing. This machine transforms raw wire into sturdy mesh products. These products are essential for security, filtration, and reinforcement.

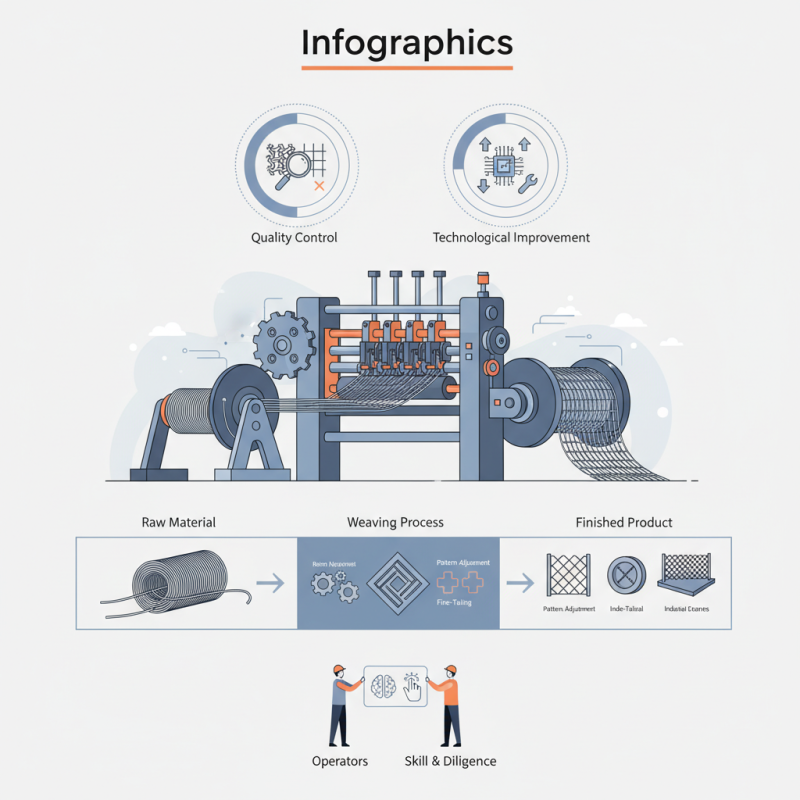

Understanding how this machine operates is crucial. At its core, the wire mesh weaving machine utilizes a systematic process. It interlaces wire strands, creating a robust structure. Different patterns and designs come from adjustments in the weaving process. Fine-tuning settings can be challenging, leading to potential flaws in the final product. Operators must pay close attention to detail.

The applications of wire mesh are widespread. From fencing to industrial filters, its versatility is striking. However, not all produced mesh meets stringent quality standards. It raises questions about the production process. Continuous improvement in technology is necessary to address these concerns. Overall, the wire mesh weaving machine is critical in producing reliable mesh products, yet it demands both skill and diligence in operation.

What is a Wire Mesh Weaving Machine?

A wire mesh weaving machine is a specialized tool for creating various types of wire mesh. It primarily uses strands of wire interwoven to form a strong, grid-like structure. This equipment is essential in many industries, including construction, agriculture, and manufacturing.

Operating a wire mesh weaving machine involves several steps. First, wire is fed through the machine, where it is shaped and cut to the desired length. The machine’s mechanism interlaces the wires accurately to ensure a consistent pattern. Each mesh type may require specific settings and adjustments. Users must often calibrate the machine to achieve desired tightness or spacing. This process can be meticulous.

While the technology is impressive, challenges can arise. Misaligned wires or improper tension may create defects in the mesh. These issues often require reevaluation and adjustment of the machine settings. Users sometimes overlook the importance of inspecting the finished product for quality. Inconsistent mesh can lead to problems in its application, reflecting the need for careful monitoring and problem-solving throughout production.

Key Components of a Wire Mesh Weaving Machine

A wire mesh weaving machine plays a crucial role in various industries. Understanding its components helps in grasping how it operates. Key elements include the warp and weft systems. The warp consists of vertical wires, while the weft involves horizontal threads. Together, they form the mesh structure, often used in construction and filtration sectors.

The machine's primary mechanism is the loom. The loom interlaces the warp and weft, creating desired mesh patterns. According to industry reports, the global wire mesh market is expected to reach $10 billion by 2025. This growth highlights the machine’s efficiency in meeting demand. Adjustments in tension levels are essential for quality control. Yet, improper settings can lead to uneven mesh patterns. Regular maintenance also plays a vital role in machine longevity.

Another significant component is the drive system. It powers the weaving process, impacting speed and precision. Research indicates that enhanced automation in these machines boosts productivity by 30%. However, automation can also pose challenges. It may require skilled operators to manage complex tasks. Balancing automation and manual intervention is vital for optimal results in wire mesh production.

What is a wire mesh weaving machine and how does it work? - Key Components of a Wire Mesh Weaving Machine

| Component | Description | Function |

|---|---|---|

| Weaving Mechanism | The primary system that interlaces wires to form mesh structures. | Creates different mesh patterns depending on wire arrangement and tension. |

| Feeding System | Holds and supplies wire to the weaving mechanism. | Ensures consistent wire supply for uniform mesh production. |

| Warping Unit | Prepares and aligns wires before weaving. | Enhances production efficiency by organizing wire layout. |

| Control Panel | Interface for operators to manage machine settings. | Allows for adjustment of weaving patterns and speeds. |

| Cutting Unit | Cuts completed mesh into specified sizes. | Facilitates handling and packaging of the final product. |

The Weaving Process: Step-by-Step Guide

Wire mesh weaving machines are vital in manufacturing various mesh products. The weaving process involves several key steps. Initially, raw materials, typically metal wires, are prepared. These wires come in different diameters and materials, depending on the final product's requirements.

The weaving process starts with the setup of the machine. Wires are threaded through the machine's shuttle. The shuttle moves back and forth, weaving strands together. Each pass creates a new row of mesh. Reports indicate that modern machines can produce up to 300 meters of mesh per hour. However, factors such as wire tension and spacing affect the output quality.

After weaving, the mesh undergoes inspection. Quality control ensures the mesh meets industry standards. Common issues include inconsistencies in tension and misalignment. These flaws can lead to structural weaknesses. Thus, operators must remain vigilant throughout the process. The intricate nature of weaving requires skill and attention to detail.

Types of Wire Mesh Produced by Weaving Machines

Wire mesh weaving machines produce various types of wire mesh. The texture and application depend on the weaving technique used. Some popular types include plain weave, twill weave, and Dutch weave. Each type has unique characteristics that make it suitable for specific uses.

Plain weave mesh is simple and sturdy. It has equal warp and weft wires that cross each other at right angles. This design provides good tensile strength. However, it may lack flexibility compared to other types. On the other hand, twill weave offers a more complex pattern. It creates diagonal lines across the mesh. This results in a more pliable material. The added flexibility makes it ideal for industrial applications where movement is essential.

Dutch weave mesh consists of tightly packed wires. It's designed for filtration applications. The dense structure allows for high flow rates while keeping particles contained. This type may require a more intricate weaving machine. Each design reflects different priorities, from strength to filtration capacity. There's always room for improvement in the weaving process, ensuring quality remains a focus. The challenge lies in balancing efficiency with precision.

Types of Wire Mesh Produced by Weaving Machines

Applications and Industries Utilizing Wire Mesh Weaving Machines

Wire mesh weaving machines are pivotal in various industries. They produce mesh used in construction, agriculture, and filtration. The machinery weaves wires into grids, providing strength and flexibility. According to a report by MarketsandMarkets, the global wire mesh market is projected to reach $6.5 billion by 2025. This highlights the rising demand for wire mesh across sectors.

In construction, wire mesh reinforces concrete structures. It enhances durability and reduces cracking. In agriculture, mesh is often used for fencing and crop protection. It offers a sturdy barrier against animals. The food and beverage industry also benefits from wire mesh, employing it for filtration and safety measures. A study from Grand View Research notes a 7% growth in demand for industrial filters, largely due to increased safety regulations.

Despite its many uses, challenges exist. The production process requires precision. Any misalignment can lead to inconsistencies in mesh quality. Quality control is essential, yet often overlooked in smaller operations. Additionally, evolving industries must adapt to technological advancements. Failure to do so risks falling behind competitors.