Home Building Wire UL Type MC Armored VFD, Multi-Conductor, 600/1000 V

UL Type MC Armored VFD, Multi-Conductor, 600/1000 V

Construction

Voltage

600V

Optional: 1000V

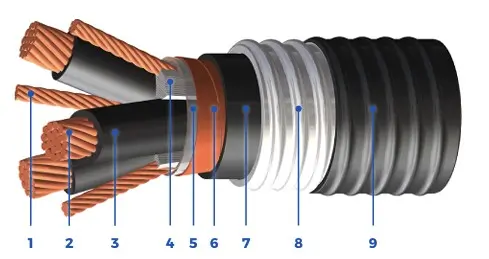

Product Construction

- Insulation:

- FR XLPE (XHHW-2 rated)rated: 90°C wet / dry Shielding:

- Dual helically applied copper tape shield

- Shielding:

- Dual helically applied copper tape shield

- Armour:

- Aluminum Interlocking Armor (AIA) (standard)

- Steel Interlocking Armor (SIA) (optional)

- Jacket:

- FRPVC outer black or yellow jacket (standard) rated: 90°C to -40°C

- Thermoset CPE optional)

- Thermoplastic CPE (optional)

- Thermoplastic LSZH (optional)

- Available in:

- Custom insulation / jacket colours

- TC-ER (optional)

Certifications

Certifications/Compliances

- UL 1569, Metal Clad Cables (MC)

- UL 44, Thermoset Insulated Wires and Cables

- UL 1685 / FT4, Vertical Tray Flame Test rated

- IEEE 1202 / 383 (70,000 BTU / hr), Vertical Flame Test rated

- ICEA T-30-520 (70,000 BTU / hr), Vertical Flame Test rated

- XLPE (XHHW-2 rated), 90°C wet / dry

- UV sunlight resistant SUN RES (all colours)

- (Direct burial rated)

- -40°C cold bend rated

- Rated for use in hazardous locations:

- Class I Zone 2 (Div 2)

- Class II Zone 20, 21 (Div 1)

- Class II Zone 22 (Div 2)

Colour Coding

- 3C Black, # coded

- Method 4 (optional)

Properties

- Tri-sectional Grounding Conductors

- Stranded Bare (ASTM B8) Annealed Copper Conductors

- FR XLPE (XHHW-2 Rated) Insulated Conductors

- Polypropylene Fillers

- Polyester Separator Tape

- Dual Helically Applied Bare / Tinned Copper Tape Shield

- FR PVC Inner Protective Jacket

- Aluminum Interlocked Armor (AIA) (standard)

- FR PVC Outer Protective Jacket

| Part Number | Number of Conductors | Conductor Size | Ground Wire Size (uninsulated) | OD Over Inner Jacket | Nominal Diameters | Cable Weight | Ampacity | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius (Pull) | |

| Over Armour | Overall Cable | |||||||||

| (AWG/kcmil) | (AWG/kcmil) | (in/mm) | (in/mm) | (in/mm) | (lbs/1000ft)/ (kg/km) | (30°C ambient) | (lb/kg) | (in/mm) | ||

| 2C61HU1203003DR | 3 | 12 | 3 x 16 | 0.439 / 11.1 | 0.678 / 17.2 | 0.798 / 20.3 | 386 / 574 | 30 | 157 / 71 | 14.4 / 365 |

| 2C61HU1003003DR | 3 | 10 | 3 x 14 | 0.500 / 12.7 | 0.740 / 18.8 | 0.900 / 22.9 | 538 / 800 | 40 | 249 / 113 | 16.2 / 412 |

| 2C61HU0803003DR | 3 | 8 | 3 x 14 | 0.657 / 16.7 | 0.897 / 22.8 | 1.057 / 26.9 | 769 / 1144 | 55 | 397 / 180 | 19 / 483 |

| 2C613U0603003DR | 3 | 6 | 3 x 12 | 0.737 / 18.7 | 0.977 / 24.8 | 1.137 / 28.9 | 982 / 1462 | 75 | 629 / 285 | 20.5 / 520 |

| 2C613U0403003DR | 3 | 4 | 3 x 12 | 0.838 / 21.3 | 1.042 / 26.5 | 1.202 / 30.5 | 1256 / 1870 | 95 | 1002 / 454 | 21.6 / 549 |

| 2C613U0203003DR | 3 | 2 | 3 x 10 | 1.003 / 25.5 | 1.207 / 30.7 | 1.367 / 34.7 | 1755 / 2612 | 130 | 1593 / 723 | 24.6 / 625 |

| 2C613U0103403DR | 3 | 1 | 3 x 10 | 1.129 / 28.7 | 1.334 / 33.9 | 1.493 / 37.9 | 2125 / 3163 | 145 | 2009 / 911 | 26.9 / 683 |

| 2C613U1/03403DR | 3 | 1/0 | 3 x 10 | 1.215 / 30.9 | 1.420 / 36.1 | 1.579 / 40.1 | 2498 / 3717 | 170 | 2534 / 1150 | 28.4 / 722 |

| 2C613U2/03403DR | 3 | 2/0 | 3 x 10 | 1.308 / 33.2 | 1.512 / 38.4 | 1.672 / 42.5 | 2922 / 4348 | 195 | 3194 / 1449 | 30.1 / 764 |

| 2C613U3/03403DR | 3 | 3/0 | 3 x 8 | 1.417 / 36.0 | 1.622 / 41.2 | 1.842 / 46.8 | 3621 / 5389 | 225 | 4007 / 1818 | 33.1 / 842 |

| 2C613U4/03403DR | 3 | 4/0 | 3 x 8 | 1.538 / 39.1 | 1.742 / 44.2 | 1.962 / 49.8 | 4296 / 6393 | 260 | 5078 / 2304 | 35.3 / 897 |

| 2C613U2503603DR | 3 | 250 | 3 x 8 | 1.680 / 42.7 | 1.985 / 50.4 | 2.205 / 56.0 | 5194 / 7730 | 290 | 6000 / 2722 | 39.7 / 1008 |

| 2C613U3503603DR | 3 | 350 | 3 x 6 | 1.961 / 49.8 | 2.266 / 57.6 | 2.486 / 63.2 | 6960 / 10358 | 350 | 8400 / 3810 | 44.8 / 1137 |

| 2C613U5003603DR | 3 | 500 | 3 x 6 | 2.236 / 56.8 | 2.542 / 64.6 | 2.822 / 71.7 | 9325 / 13877 | 430 | 12000 / 5443 | 50.8 / 1290 |

| 2C613U7503603DR | 3 | 750 | 3 x 4 | 2.686 / 68.2 | 2.991 / 76.0 | 3.271 / 83.1 | 13110 / 19509 | 535 | 18000 / 8165 | 58.9 / 1495 |

*Ampacity value based on National Electrical Code, Version 2020, Table 310.16. Values are corrected according to Table 310.15(C)(1) for number of Conductors.

Markets / Applications

- Transit

- Water/Waste Water Treatment

- Generation

- Communication Power & Control

- Generation – Nuclear

- Power Distribution

- Industrial Construction/Automation

- Civil Construction Projects

- Industrial

- Generation – Renewables

- Petrochem/Pulp & Paper

- Utility

- Commercial Construction Projects

- OIl & Gas

- Mining

Voltage

600V

Optional: 1000V

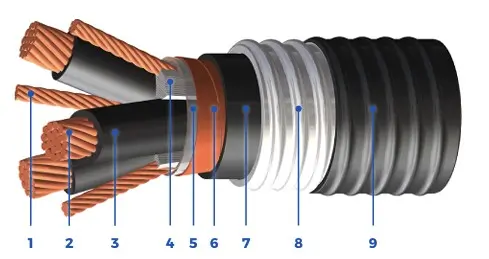

Product Construction

- Insulation:

- FR XLPE (XHHW-2 rated)rated: 90°C wet / dry Shielding:

- Dual helically applied copper tape shield

- Shielding:

- Dual helically applied copper tape shield

- Armour:

- Aluminum Interlocking Armor (AIA) (standard)

- Steel Interlocking Armor (SIA) (optional)

- Jacket:

- FRPVC outer black or yellow jacket (standard) rated: 90°C to -40°C

- Thermoset CPE optional)

- Thermoplastic CPE (optional)

- Thermoplastic LSZH (optional)

- Available in:

- Custom insulation / jacket colours

- TC-ER (optional)

Certifications/Compliances

- UL 1569, Metal Clad Cables (MC)

- UL 44, Thermoset Insulated Wires and Cables

- UL 1685 / FT4, Vertical Tray Flame Test rated

- IEEE 1202 / 383 (70,000 BTU / hr), Vertical Flame Test rated

- ICEA T-30-520 (70,000 BTU / hr), Vertical Flame Test rated

- XLPE (XHHW-2 rated), 90°C wet / dry

- UV sunlight resistant SUN RES (all colours)

- (Direct burial rated)

- -40°C cold bend rated

- Rated for use in hazardous locations:

- Class I Zone 2 (Div 2)

- Class II Zone 20, 21 (Div 1)

- Class II Zone 22 (Div 2)

Colour Coding

- 3C Black, # coded

- Method 4 (optional)

- Tri-sectional Grounding Conductors

- Stranded Bare (ASTM B8) Annealed Copper Conductors

- FR XLPE (XHHW-2 Rated) Insulated Conductors

- Polypropylene Fillers

- Polyester Separator Tape

- Dual Helically Applied Bare / Tinned Copper Tape Shield

- FR PVC Inner Protective Jacket

- Aluminum Interlocked Armor (AIA) (standard)

- FR PVC Outer Protective Jacket

| Part Number | Number of Conductors | Conductor Size | Ground Wire Size (uninsulated) | OD Over Inner Jacket | Nominal Diameters | Cable Weight | Ampacity | Max. Pulling Tension (Pulling Eye) | Min. Bend Radius (Pull) | |

| Over Armour | Overall Cable | |||||||||

| (AWG/kcmil) | (AWG/kcmil) | (in/mm) | (in/mm) | (in/mm) | (lbs/1000ft)/ (kg/km) | (30°C ambient) | (lb/kg) | (in/mm) | ||

| 2C61HU1203003DR | 3 | 12 | 3 x 16 | 0.439 / 11.1 | 0.678 / 17.2 | 0.798 / 20.3 | 386 / 574 | 30 | 157 / 71 | 14.4 / 365 |

| 2C61HU1003003DR | 3 | 10 | 3 x 14 | 0.500 / 12.7 | 0.740 / 18.8 | 0.900 / 22.9 | 538 / 800 | 40 | 249 / 113 | 16.2 / 412 |

| 2C61HU0803003DR | 3 | 8 | 3 x 14 | 0.657 / 16.7 | 0.897 / 22.8 | 1.057 / 26.9 | 769 / 1144 | 55 | 397 / 180 | 19 / 483 |

| 2C613U0603003DR | 3 | 6 | 3 x 12 | 0.737 / 18.7 | 0.977 / 24.8 | 1.137 / 28.9 | 982 / 1462 | 75 | 629 / 285 | 20.5 / 520 |

| 2C613U0403003DR | 3 | 4 | 3 x 12 | 0.838 / 21.3 | 1.042 / 26.5 | 1.202 / 30.5 | 1256 / 1870 | 95 | 1002 / 454 | 21.6 / 549 |

| 2C613U0203003DR | 3 | 2 | 3 x 10 | 1.003 / 25.5 | 1.207 / 30.7 | 1.367 / 34.7 | 1755 / 2612 | 130 | 1593 / 723 | 24.6 / 625 |

| 2C613U0103403DR | 3 | 1 | 3 x 10 | 1.129 / 28.7 | 1.334 / 33.9 | 1.493 / 37.9 | 2125 / 3163 | 145 | 2009 / 911 | 26.9 / 683 |

| 2C613U1/03403DR | 3 | 1/0 | 3 x 10 | 1.215 / 30.9 | 1.420 / 36.1 | 1.579 / 40.1 | 2498 / 3717 | 170 | 2534 / 1150 | 28.4 / 722 |

| 2C613U2/03403DR | 3 | 2/0 | 3 x 10 | 1.308 / 33.2 | 1.512 / 38.4 | 1.672 / 42.5 | 2922 / 4348 | 195 | 3194 / 1449 | 30.1 / 764 |

| 2C613U3/03403DR | 3 | 3/0 | 3 x 8 | 1.417 / 36.0 | 1.622 / 41.2 | 1.842 / 46.8 | 3621 / 5389 | 225 | 4007 / 1818 | 33.1 / 842 |

| 2C613U4/03403DR | 3 | 4/0 | 3 x 8 | 1.538 / 39.1 | 1.742 / 44.2 | 1.962 / 49.8 | 4296 / 6393 | 260 | 5078 / 2304 | 35.3 / 897 |

| 2C613U2503603DR | 3 | 250 | 3 x 8 | 1.680 / 42.7 | 1.985 / 50.4 | 2.205 / 56.0 | 5194 / 7730 | 290 | 6000 / 2722 | 39.7 / 1008 |

| 2C613U3503603DR | 3 | 350 | 3 x 6 | 1.961 / 49.8 | 2.266 / 57.6 | 2.486 / 63.2 | 6960 / 10358 | 350 | 8400 / 3810 | 44.8 / 1137 |

| 2C613U5003603DR | 3 | 500 | 3 x 6 | 2.236 / 56.8 | 2.542 / 64.6 | 2.822 / 71.7 | 9325 / 13877 | 430 | 12000 / 5443 | 50.8 / 1290 |

| 2C613U7503603DR | 3 | 750 | 3 x 4 | 2.686 / 68.2 | 2.991 / 76.0 | 3.271 / 83.1 | 13110 / 19509 | 535 | 18000 / 8165 | 58.9 / 1495 |

*Ampacity value based on National Electrical Code, Version 2020, Table 310.16. Values are corrected according to Table 310.15(C)(1) for number of Conductors.

- Transit

- Water/Waste Water Treatment

- Generation

- Communication Power & Control

- Generation – Nuclear

- Power Distribution

- Industrial Construction/Automation

- Civil Construction Projects

- Industrial

- Generation – Renewables

- Petrochem/Pulp & Paper

- Utility

- Commercial Construction Projects

- OIl & Gas

- Mining

Related products

-

UL Type MC Armored Control, Multi-Conductor, 2000 V

View Product: UL Type MC Armored Control, Multi-Conductor, 2000 VUL Type MC Armored Control, Multi-Conductor, 2000 V

These metal-clad AIA power cables are suitable for use in ventilated, non-ventilated and ladder-type cable trays, in direct burial, raceways and for exposed or concealed wiring in wet, damp or dry locations in -40°C (-40°F) environments. Applicable for use in utility, industrial and commercial applications.

SKU: 1669 Categories: UL Type MC Metal Clad Cable, UL Type TC Tray Cable, Building WireUL Type MC Armored Control, Multi-Conductor, 2000 V

These metal-clad AIA power cables are suitable for use in ventilated, non-ventilated and ladder-type cable trays, in direct burial, raceways and for exposed or concealed wiring in wet, damp or dry locations in -40°C (-40°F) environments. Applicable for use in utility, industrial and commercial applications.

MORE DETAILS -

UL Type MC Armored Control, Multi-Conductor, 600/1000 V

View Product: UL Type MC Armored Control, Multi-Conductor, 600/1000 VUL Type MC Armored Control, Multi-Conductor, 600/1000 V

Metal Clad AIA Control cables are suitable for use in ventilated, non-ventilated and ladder type cable trays, direct burial, raceways and for exposed or concealed wiring in wet, damp or dry locations in -40°C (-40°F) environments. Applicable for use in Utilities, Industrial and Commercial applications.

SKU: 1750 Categories: UL Type MC Metal Clad Cable, UL Type TC Tray Cable, Building WireUL Type MC Armored Control, Multi-Conductor, 600/1000 V

Metal Clad AIA Control cables are suitable for use in ventilated, non-ventilated and ladder type cable trays, direct burial, raceways and for exposed or concealed wiring in wet, damp or dry locations in -40°C (-40°F) environments. Applicable for use in Utilities, Industrial and Commercial applications.

MORE DETAILS -

UL Type Metal Clad Riser Armored Mineshaft Cables, 2000 V

View Product: UL Type Metal Clad Riser Armored Mineshaft Cables, 2000 VUL Type Metal Clad Riser Armored Mineshaft Cables, 2000 V

Riser cables are designed for vertical applications to prevent cable core slippage and are suitable for use in mineshaft and for environments that require self-supporting lengths. Typically used in Mining, Utilities, Industrial and Commercial applications.

SKU: 1677 Categories: UL Type MC Metal Clad Cable, UL Type TC Tray Cable, Mineshaft Cable for Vertical InstallationUL Type Metal Clad Riser Armored Mineshaft Cables, 2000 V

Riser cables are designed for vertical applications to prevent cable core slippage and are suitable for use in mineshaft and for environments that require self-supporting lengths. Typically used in Mining, Utilities, Industrial and Commercial applications.

MORE DETAILS